S&S Cycle Super Stock and Special Application Crankcases for 1936-99 Big Twin Engines User Manual

Page 15

15

I- Gearcover

NOTES

S&S® crankcases accept S&S and stock gearcovers. Mounting holes are 1⁄4-20 thread. Tighten to 8-10 ft-lbs. in all applications. Mounting screws are not

•

furnished, but are available separately.

Some aftermarket gearcovers have incorrect machining that may cause poor alignment of oil passages, pinion shaft, cam and dowel locations.

•

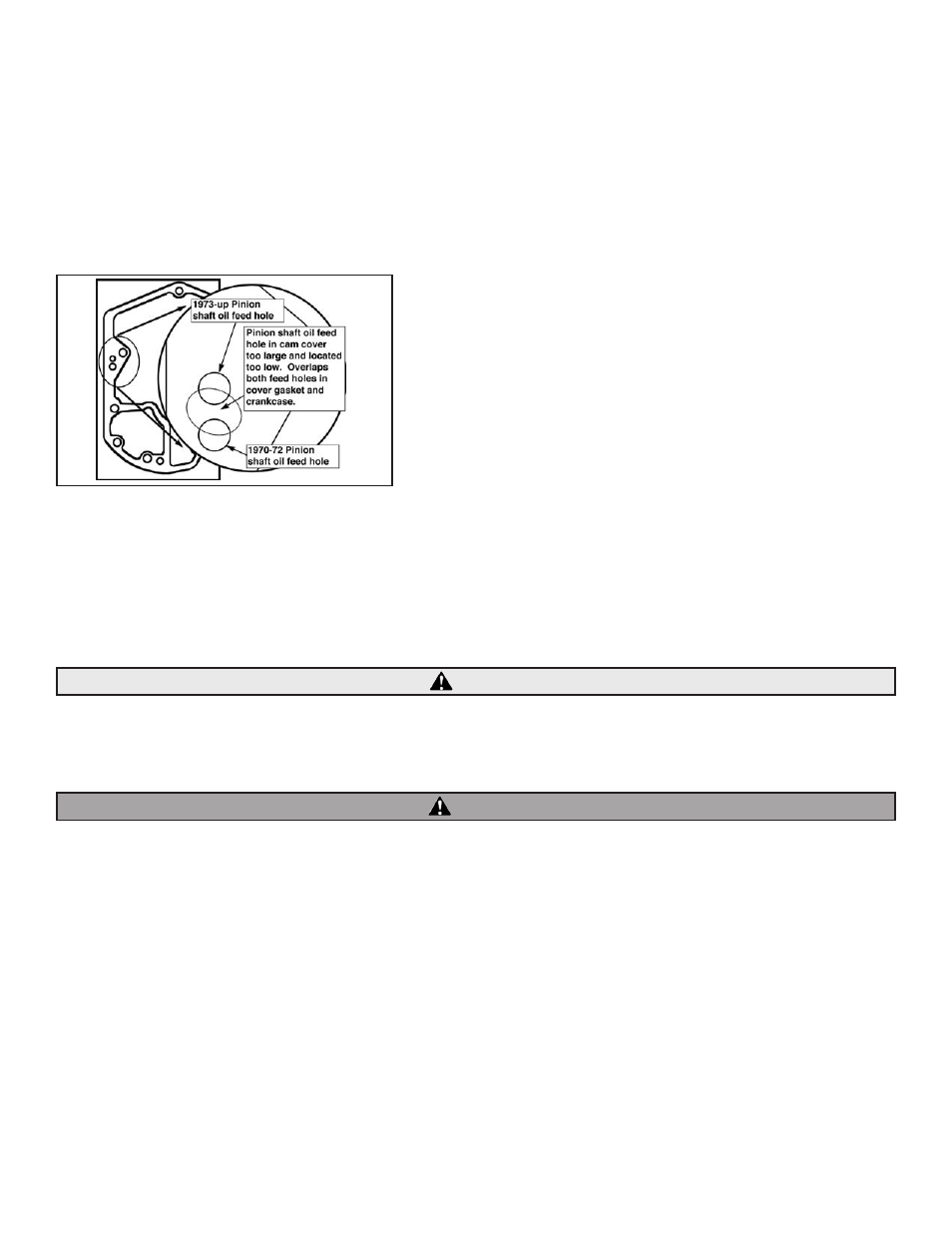

Incorrect machining on some 1970 to present aftermarket covers may also cause poor alignment between oil passage in gearcover pinion shaft oil

supply passage in crankcase. See Figure 5. Additionally, S&S has found some covers to have porosity between pinion shaft oil supply and crankcase

breather passages. Result is that high pressure oil intended for top end is diverted to breather cavity or bottom end, starving hydraulic tappets, rocker

arms, etc. as a result. Problem may be intensified by heat; as engine temperature increases, oil thins and pressure drops, flywheel cavity becomes flooded

with oil, scavenging mechanism becomes overwhelmed and excessive oil is blown out crankcase breather. Engine damage may also occur.

If stock gearcover is used, it must be correct design for year group. 1970-1972 style cover could interfere with oil circulation if used with 1973 and later

•

end oiling pinion shaft. Venting crankcase pressure out hole E (See Picture 6) requires 1973-1992 style gear cover. Operating engine with hole E open

and 1993-up style gearcover will cause large oil losses out crankcase.

1973 - 1992 style gear cover must be used if crankcase pressure is vented directly out crankcase rather than through cylinder heads as in 1993-up style

•

big twin. S&S® recommends venting out hole E in crankcase AND cylinder heads if 1992-earlier gear cover and 1993-up rocker arm covers are available.

S&S supplies all long blocks with correct gearcover for dual vent arrangement. S&S rocker covers are compatible with cylinder head venting if umbrella

valves are installed correctly (See S&S Rocker Cover Instructions 51-1051). If only cylinder head venting is used, hole E in Picture 6 must be plugged.

Gearcover misalignment with crankcase alignment dowels, pinion shaft and/or camshaft may cause abnormal stresses resulting in

•

shaft breakage and other engine damage not covered under warranty.

Incorrect oil passage machining in gear cover may cause low oil pressure resulting in extensive engine damage not covered under

•

warranty.

Attempting to use 1993-up stock gearcover on engine with direct crankcase venting will result in large oil losses with possible loss of

control of motorcycle and serious injury to operator and others.

1- Compatibility

a- 1936 to 1969 engines - Stock or S&S gear covers may be used with S&S generator style crankcases. See notes and cautions above.

b- 1970 to present - Use appropriate year group, 1970 to 1972, 1973 to 1992 or 1993 to present, stock or S&S gearcover. Do not use

1970 to 1972 type with 1973 and later end oiling pinion shaft. See notes and cautions above.

2- Gearcase mounting hardware

a- To use stock gear covers with chamfered mounting holes, fasteners with identical chamfers must be used. Some builders have used

S&S 1⁄4-20 x 3⁄4” (S&S 50-0072) Phillips oval head screws usually used to install S&S teardrop air cleaner covers. As an alternative, S&S offers

special 1⁄4” screw adapter washers, S&S 33-5308 that are used with regular 1⁄4 -20 x 1” socket head cap screws such as (S&S 50-0084) or

1⁄4 -20 x 7⁄8” 12 pt. cap screws (S&S 50-0068). Screw thread engagement in cases must be at least 1⁄2”. To check, install screw and washer, if

used, in gear cover and measure amount of screw that protrudes past gear cover gasket surface. Allow for gasket thickness.

b- Stock gearcovers utilize several different length screws with washers. Screws in S&S cover kits are identical in length. They are

1⁄4-20 x 11⁄4“ (S&S 50-0008). Washers supplied are S&S 50-7020.

Figure 5

CAUTION

WARNING