S&S Cycle Super Stock and Special Application Crankcases for 1936-99 Big Twin Engines User Manual

Page 4

4

NOTE: This step is not necessary in S&S® crankcases manufactured with large wiring recess.

Do not increase depth of recess. Remove minimum amount of material that will allow alternator stator to mount on crankcase without

crimping wiring harness. Removing excess material may weaken crankcase.

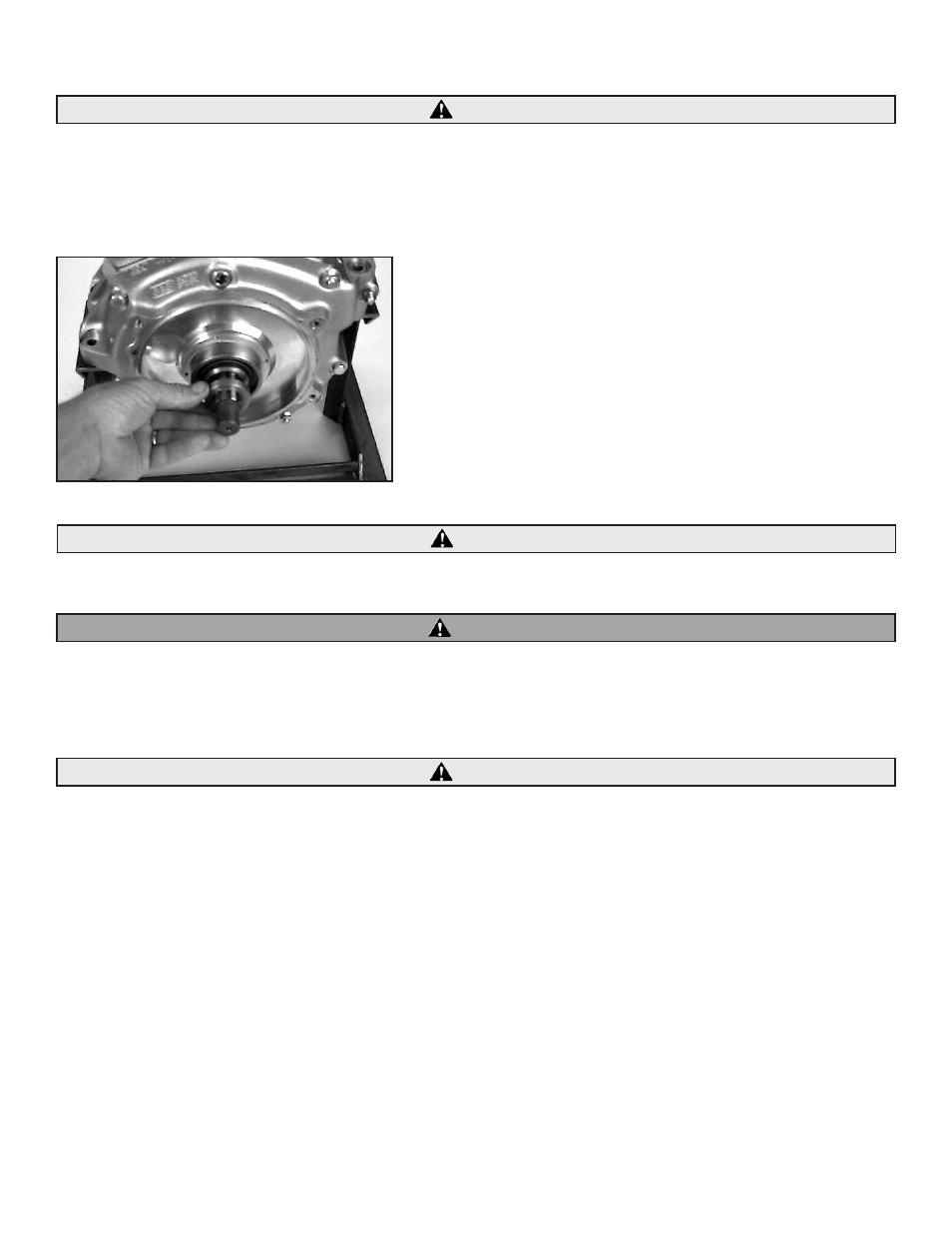

2- After installation of flywheel assembly, S&S drive sprocket spacer 31-4011 and Timken® main bearing seal, place S&S spacer 31-4033

(not provided) on sprocket shaft between spacer 31-4011 and alternator rotor. See Picture 2. Dimensions of spacer 31-4033 are 1.13”

(i.d.) x 1.73” (o.d.) x .325” (thickness).

Failure to use spacer 31-4033 with 45 amp alternator will cause rotor to bottom against crankcase when sprocket nut is tightened, causing

damage to crankcase, rotor, or both.

To insure safe operation of motorcycle, these operations must be performed correctly and in a professional manner.

3- After completing engine assembly and installing engine in frame, check primary chain run-out according to procedure in Harley-

Davidson® service manual. Maximum permissible run-out is .030”. Prior to operation of motorcycle confirm that primary chain and

drive assembly rotate freely and without contacting alternator wiring harness, crankcase, or other components.

Incorrect installation of engine or driveline could cause loss of control of motorcycle with serious consequences to operator and other.

B- Clean crankcases in hot soapy water or solvent to remove any dirt or contamination which may have been introduced during shipping,

handling, or set-up. If 1973-1980 stock shovelhead oil pump is to be used, refer to note in section 3-f, Oil Supply Passages, prior to final

preparation.

C- Carefully clear all oil passages with compressed air.

Compressed air and particles dislodged by compressed air are potentially harmful. Wear protective goggles when using compressed air and always

direct air stream away from yourself and others nearby.

3- Hardware Identification and Installation

NOTES:

Some hardware supplied in crankcase kits may not be needed.

•

When installing hardware, be careful not to cross-thread fittings or damage threads. Damage caused by improper installation of hardware will not be

•

covered under warranty.

To prevent galling, apply anti-seize compound or Teflon® tape to threads of all steel fittings prior to installation in crankcase.

•

If Teflon® tape is used, loose tape must not enter crankcase or oil passages. Do not apply tape to first 2-3 threads that screw into hole. If fittings are

•

removed or replaced be sure no tape shreds remain in holes. Tape shred could block oil passages causing restriction of oil flow.

CAUTION

CAUTION

WARNING

Picture 2

CAUTION