Caution – S&S Cycle Bore Stroker Kit 3 3/16 for Harley-Davidson Sportster Models User Manual

Page 8

●

Crankcase oil scavenging can be greatly improved on 1957 to

1971 engines by converting to 1972 and later style breather

parts combination. If your engine is 1971 or earlier, we

strongly recommend purchase of 1972 and later pump

breather gear, H-D

®

#26331-72 and corresponding gear

retainer lock ring, H-D

®

#11002. These parts are used in place

of early pump breather gear, H-D #26331-60, because slot in

early version is too wide and requires the removal of too

much material from pump body to achieve desired results.

When later parts are used in early pump, scavenger gear,

part H-D #26315-62, must be installed with flat side of gear

facing retainer lock ring.

All reference to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding Harley-Davidson

®

part

number shown.

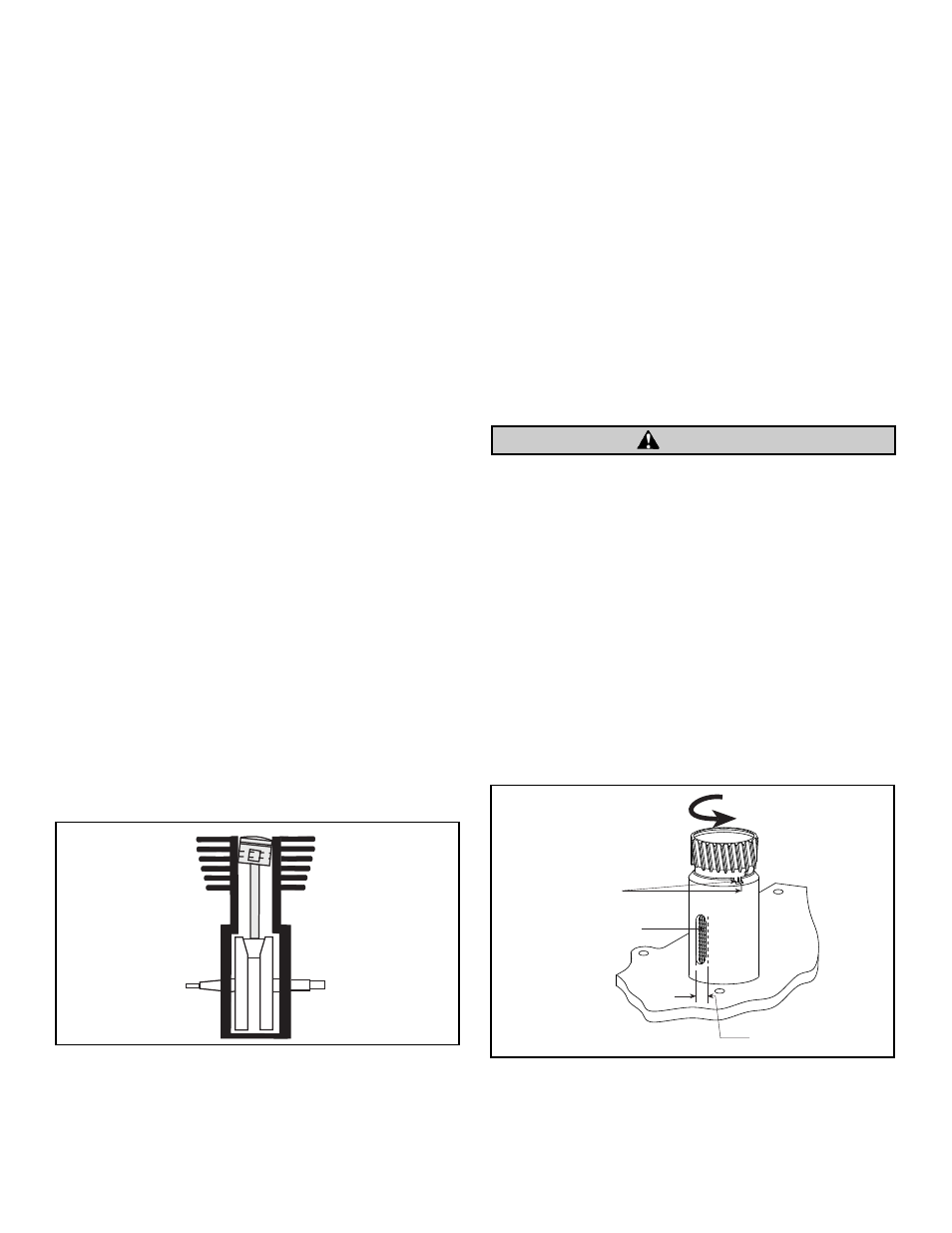

To check and correct crankcase breather timing, perform

following steps:

A.

Before installing oil pump, turn pump gear

counterclockwise until sleeve hole in gear aligns with

slot in pump body. Place .002” shim in opening and

reverse gear until tight. Scribe mark across pump gear

sleeve and pump body at small timing notch on top

edge of body. See Figure 5.

NOTE - Pump gear sleeve is very hard and scribing mark may be

difficult. It may be advantageous to coat top ring of sleeve just

below teeth with Dykem Blue to make marking easier.

B.

Install and time pump in normal manner as in final

assembly.

C.

Install degree wheel on sprocket shaft, and position

pointer at 0° when front piston is at top dead center

(TDC) position.

D.

Rotate front piston to 25° ATC. Be sure oil pump drive

gear is firmly butted against shoulder on pinion shaft.

E.

If scribe mark on pump gear is to left of scribe mark on

body, grind material off engine side of pump drive gear

to allow it to move farther onto shaft until scribe marks

line up. If scribe mark is to right, place shim between

pump drive gear and pinion shaft shoulder to line up

marks. Big twin cam thrust washers, H-D

®

#25550-36,

can be used for this purpose, but are marginal because

they fit pinion shaft poorly. For a better fit we fabricate

our own washers to exact size.

F.

Rotate crankshaft so front piston is at 85° ABC (after

bottom center).

G.

Make a second scribe mark on pump to align with first

scribe mark on body.

H.

Remove pump and carefully grind or file slot wider in

body towards cam cover until it closes at second scribe

mark. Proceed with caution. Do not remove more

material,than absolutely necessary. If unsure, contact

S&S before you make a mistake.

Improper breather timing causes poor oil scavenging from

flywheel cavity and incorrect crankcase air pressure. These

conditions may cause unwarranted engine oil leaks around

gaskets and seals and probable oil burning due to oil blow by

past piston rings. Removal of excessive material from slot

opening is irreversible and damage to body may result.

I.

During final assembly, place oil pump drive gear on

pinion shaft, and time pump in normal fashion. If

material was removed from flywheel side of oil pump

drive gear, it may be necessary to shim between pump

drive gear and pinion gear.

NOTE - Pinion gear must be flush with or extend out slightly past

splines on pinion shaft so pinion gear end play shim does not

contact pinion shaft splines instead of pinion gear.

8

Figure 4

Scribe mark

Breather gear just

starting to open

Enlarge closing

side only

Figure 5

CAUTION