Warning caution, Caution – S&S Cycle Bore Stroker Kit 3 3/16 for Harley-Davidson Sportster Models User Manual

Page 6

●

Some solvents, degreasers, gasoline and other chemicals are

harmful to skin, eyes and other body parts. Many items are

flammable and present a fire hazard. Read manufacturer’s

instruction label for proper use. Use in well ventilated area

and wear protective clothing when using them to avoid

personal injury.

●

Compressed air and particles dislodged by compressed air

are harmful to eyes and body. Wear protective goggles

when using compressed air and always direct air stream

away from body parts such as hands and eyes and other

people near you.

Perform following steps when assembling flywheels:

A.

Thoroughly clean all parts to be used. This includes

mainshafts, main bearings, connecting rods, rod

bearings, crankpin nut retainers and screws if they

are to be used, keys and flywheels including tapers

and keyways.

Burrs, dirt, filings, etc. left on flywheel assembly parts may

circulate in oil damaging other parts possibly causing

engine failure.

B.

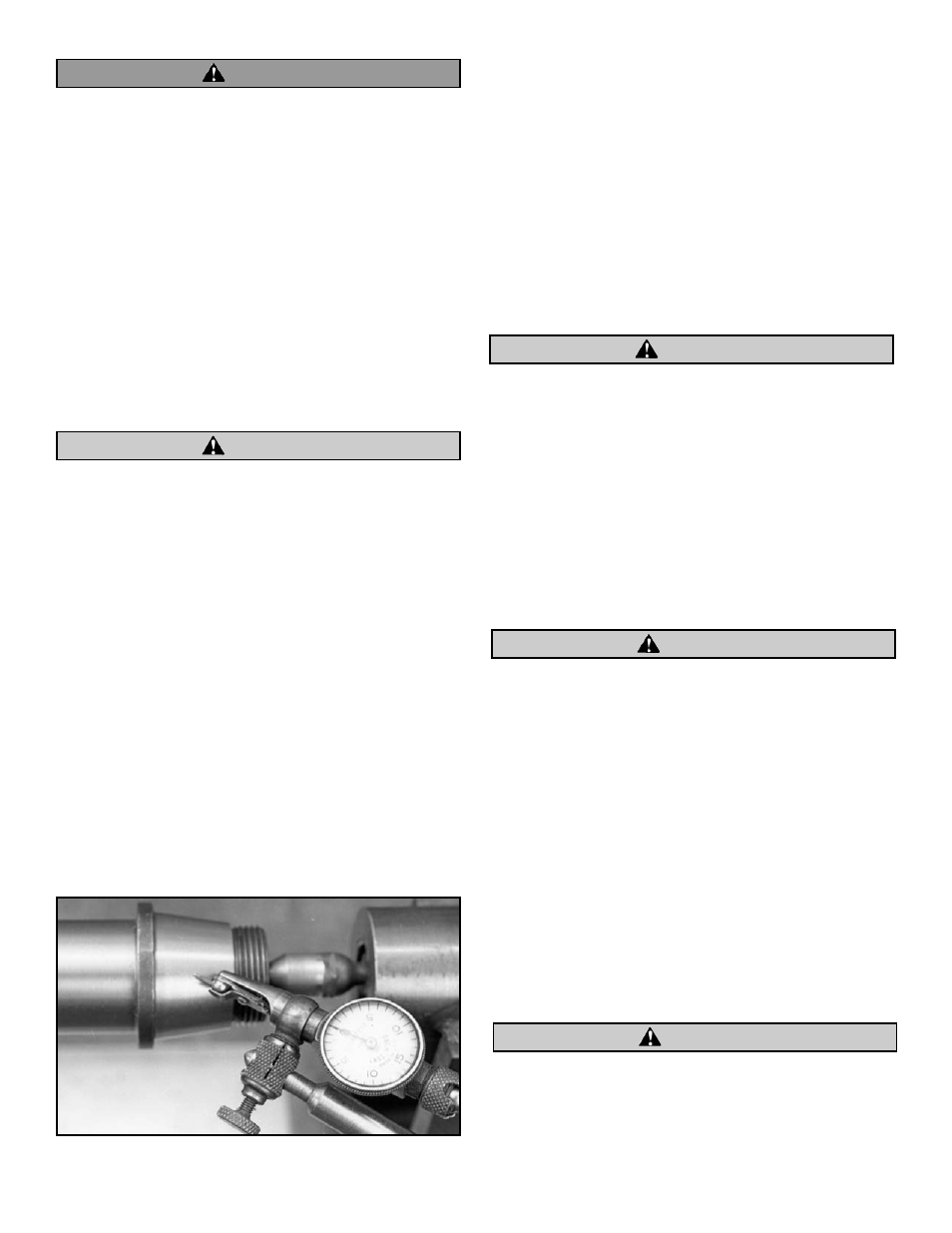

Check both mainshafts between centers for taper

surface to bearing surface concentricity.

Make sure

centers on shafts are clean beforehand. If tapers and

bearing surfaces are concentric with each other and

with center, then truing will be easier. See Picture 7.

NOTE - S&S

®

prefers to see .0003” or less of runout between taper

and bearing surface with an absolute maximum of .0005”. S&S

shafts are .0003” or less.

C.

Inspect keyways and oil holes for burrs in flywheels and

remove if necessary.

D.

With key in shaft, insert into respective tapered hole in

flywheel and check to see that key does not bottom in

groove. If key bottoms out, file flat side of key, not

rounded side, until shaft with key in place fits in

flywheel without bottoming out. Check crankpin and

crankpin key also.

E.

Reclean mainshaft tapers, crankpin and flywheel tapers

with lacquer thinner.

F.

Assemble mainshafts in respective flywheels. Coat taper

and threads of each shaft with green Loctite

®

RC 609 or

Omni Fit 1730 during assembly. Install crankpin in

camside flywheel using Loctite

®

also. Tighten all nuts to

at least factory torque specs minimum. When S&S shafts

are used, follow instructions included with them.

NOTE - S&S recommends to tighten nuts very tight. We use a

3

⁄

4

”drive breaker bar and a five foot piece of pipe when

assembling flywheels.

After right side flywheel, pinion shaft and crankpin are

assembled, blow air through pinion shaft oil feed hole to check

for blockage.

Partially or completely blocked oil feed passageways may

cause irreversible damage to bearings and other engine

components.

G.

Measure width of female rod on crankpin end. See

Picture 8. Measurement should be 1.481” to 1.483”.

H.

Assemble left and right flywheels and moderately

snug nuts. Do not worry about them being true.

Measure distance between connecting rod thrust

pads. See Picture 9.

NOTE - S&S recommended rod side play is .015” to .035”.

Rod Side Play = (Distance from Pad to Pad) - (Female Rod Width)

Incorrect connecting rod side play may cause excessive rod

side thrusting and potential damage to rods, flywheels and

other engine components.

If difference is less than .020”, female rod must be ground on

sides as final tightening will pull wheels closer together. Rod side

play diminishes about .015” when crankpin nut is final tightened.

Take equal amounts off each side if amount to be removed is

more than .010”. If there is no rod side play try different

crankpin. If rod side play is more than .035”, try different

crankpin. We have run side play of as much as .045” without

serious consequences. If side play is excessive and different

crankpins do not correct problem, contact us.

NOTE - If material is removed from sides of female rod, overall

width of bearing cages must be reduced so bearings and cages

are free to float with rods without contacting flywheel thrust

pads. Bearing cage side clearance of .008 to .020 less than rod

width is recommended.

Connecting rod bearing and cage assemblies that are wider

than female rod may become damaged upon contact with

flywheel thrust pads. Damaged rod bearing assemblies

and/or foreign material from damaged components

circulating in oil could cause further destruction and possible

failure of other engine parts.

6

WARNING

CAUTION

Picture 7

CAUTION

CAUTION

CAUTION