Caution warning – S&S Cycle Bore Stroker Kit 3 3/16 for Harley-Davidson Sportster Models User Manual

Page 3

NOTES

●

Oil rings will usually touch and/or cross oil return holes with

installation of stroke 4

7

⁄

16

” or longer. Strokes shorter than

4

7

⁄

16

” do not require this step.

●

Method given below was tried as an experiment when we

installed an S&S

®

4

5

⁄

8

” stroker kit in our 1972 model. All steps

except H and I were performed. Object was to see if engine

would smoke and use excessive oil which it did not. Several

customers have also reported similar successes when leaving

stock holes open. Based upon our test results and these

customer reports, we feel relatively confident in

recommending that stock oil return holes be left open even

though we have tried it on only one test engine and cannot

guarantee that it will work in all instances. If you decide to

try leaving the stock oil return holes open, perform all of the

following steps except H and I.

For strokes 4

7

⁄

16

” and longer, perform following steps:

A.

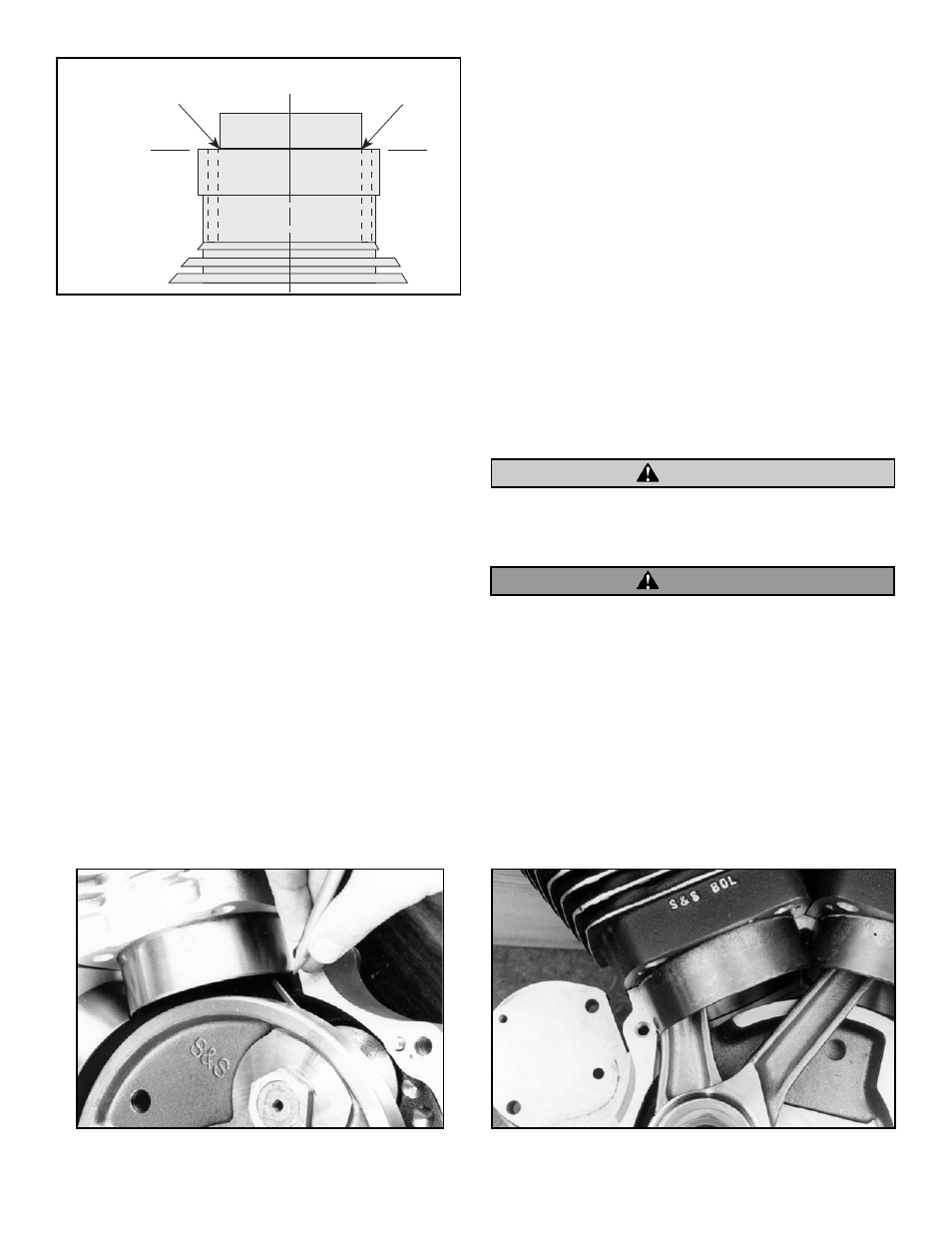

Place cylinder with head gasket surface down on bench.

Lay out lines “A” on cylinder base gasket surface so they

are directly above centers of old oil return holes which

exit into cylinder bore. See Figure 1.

B.

Lay piece of

1

⁄

8

” thick material against cylinder spigot 90°

to lines A and scribe lines “B”.

C.

Center punch points where lines A and B intersect.

D.

Drill

3

⁄

16

” diameter hole at each point perpendicular to

gasket surface to meet passage coming from cylinder

head. Be careful not to break drill when breaking into

existing passage as holes may be slightly misaligned and

drill may tend to grab.

E.

Center punch corners where lines A intersect spigot.

See Figure 2.

F.

Drill

3

⁄

32

” diameter hole at each point at 60° angle into

cylinder bore.

G.

Enlarge

3

⁄

32

” holes from inside cylinder bore with

3

⁄

16

”

diameter drill.

H.

Braze or weld old oil return holes shut. .

NOTE - Be sure person who does work knows how to work with

cast iron as cylinders may crack or develop hard spots if not done

properly

I.

Repeat step D to remove braze or welding material that

may be obstructing oil return passages.

J.

Blow air through passages to remove chips, etc.

Dirt, filings, etc. left in oil return passageways may circulate

in oil damaging other parts possibly causing engine failure.

●

Some solvents, degreasers, gasoline and other chemicals are

harmful to skin, eyes and other body parts. Many items are

flammable and present a fire hazard. Read manufacturer’s

instruction label for proper use. Use in well ventilated area

and wear protective clothing when using them to avoid

personal injury.

●

Compressed air and particles dislodged by compressed air

are harmful to eyes and body. Wear protective goggles

when using compressed air and always direct air stream

away from body parts such as hands and eyes and other

people near you.

3

Centerpunch, then

drill

3

⁄

32

" diameter hole

Figure 2

Picture 2

Picture 3

CAUTION

WARNING

Center-punch, then drill

3

⁄

32

”

diameter hole