S&S Cycle Standard & Easy Start Gear Drive Camshafts for 2007–up Harley-Davidson Big Twin and 2006 Dyna Models User Manual

Page 3

Important Notes Regarding Easy Start Camshafts:

• Stock EFI engines require a minimum of 80 PSI cranking

compression, checked with the throttle open, for the ECU to fire the

spark plugs.

• The easy start cams were designed to work with the compression

ratio and displacement combinations that the cam was intended

for. Due to a near infinite number of engine combinations,

manufacturing tolerances, or if the cam is used outside our

recommended compression ratios, occasionally an engine may not

build the required compression to start the bike. For these cases we

offer cams that do not release as much compression. Please call our

technical department at 1-608-627-8324.

• Cranking compression numbers are no longer a valid health check

of the engine. We recommend performing a leak down test.

• S&S recommends that you install new lifters when installing new

cams

• If any service work is performed and the lifters are not replaced, the

lifters must be installed in the original position and orientation.

• If the lifters have been disassembled or bled down for any purpose,

the starter may have difficulty with the initial start. Although the

decompression lobe lifts the lifter body, the lifter is not pumped up

and it will not lift the exhaust valve. You may need to remove the

spark plugs and crank the engine to get oil pressure to the lifters.

• There is no service required with these cams. If you ever have the

cams out for any reason, inspect the mechanism for wear and verify

that the lever operates smoothly.

1- Disassembly

1. Remove pushrods.

a- Remove pushrod cover clips with a small screwdriver and

compress pushrod covers to expose pushrods. Lift rear tire of

motorcycle with a suitable jack. Rotate the engine until one

of the cylinders is on “top dead center compression stroke”

(TDCC). TDCC can be found by rolling the rear tire forward

while watching or feeling the pushrods move through their

travel. When BOTH pushrods are at the lowest point of their

travel and the piston for that cylinder is at TDC, the engine is at

TDCC. Rotate the pushrods to ensure there is no load on them.

If the pushrods will not rotate freely by hand, either the engine

is not on TDCC, or the lifters need to bleed down. It may be

necessary to let the lifters bleed down for a few minutes before

the pushrods will rotate freely.

b- If S&S adjustable pushrods will be used for re-assembly, the

stock pushrods may be cut to remove them at this time. When

cutting pushrods, S&S recommends a bolt cutter be used as it

is the cleanest method. Be sure to only cut the pushrods that

are not loaded and rotate freely by hand.

Cutting the pushrods with a saw may result in metal chips entering

the engine and causing extensive damage which will not be covered

under warranty.

Cutting pushrods without relieving valve spring force on the

pushrods may result in injury.

c- If stock one piece pushrods are to be re-used, remove the gas

tank and rocker box covers. Remove the rocker arm support by

first removing the two smaller bolts which hold the breather

cover in place. Next break loose the four bolts holding the

rocker arm support plate in place with an alternating pattern.

Remove the four rocker arm support plate bolts, and then

the rocker arm support assembly. The pushrods may now

be removed by sliding them up into the head slightly and

then pulling the bottom of the pushrod towards you. Mark

the original pushrod location as it is removed to ensure it is

replaced in its original position. The intake pushrod is shorter

than the exhaust pushrod. Interchanging the intake and

exhaust pushrods upon reassembly, will cause the intake valve

to stay open on the compression stroke and the engine will not

run.

d- Rotate the engine so the other cylinder is on TDC compression

and repeat the above procedure.

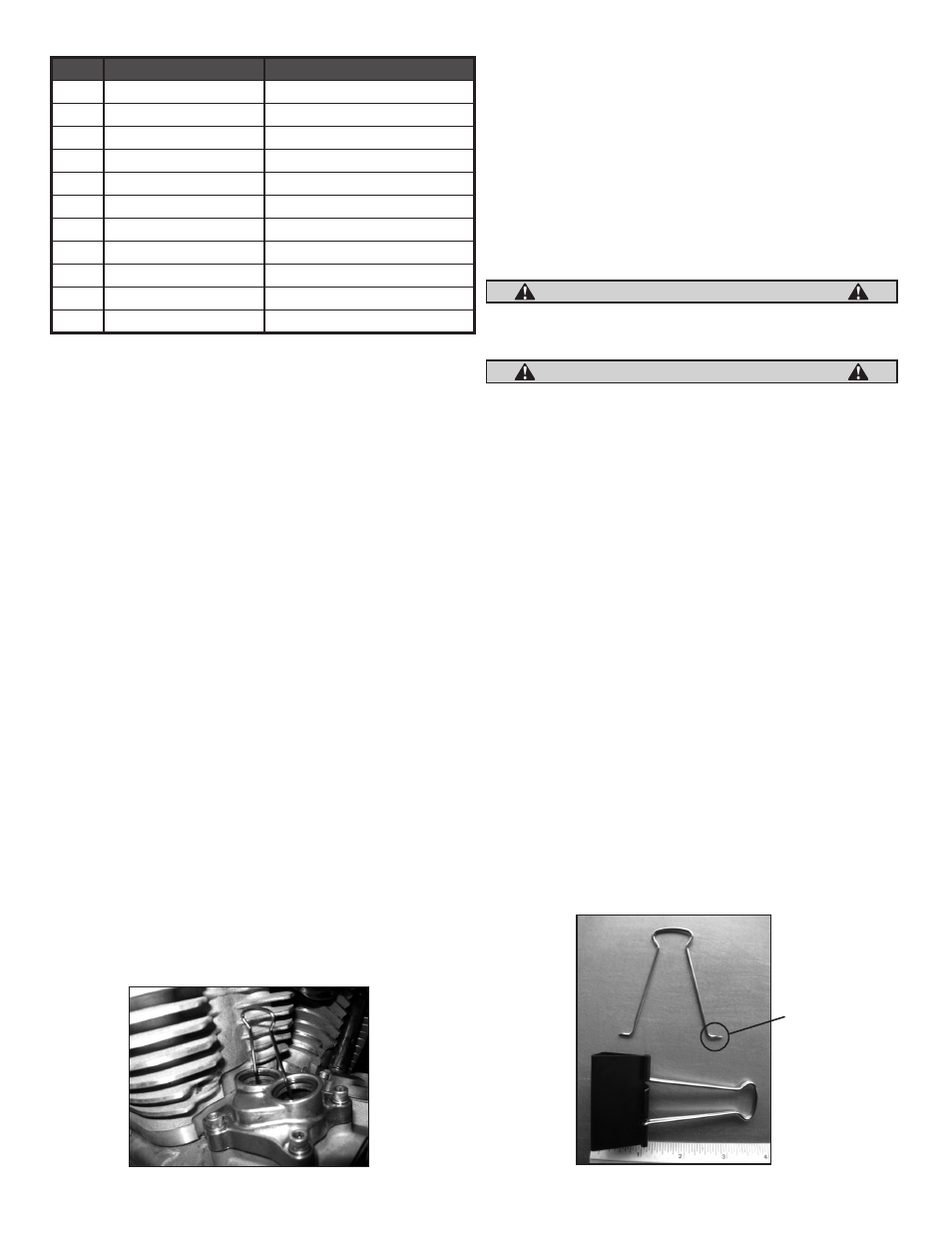

2. Remove cam cover and gasket. Secure lifters with a magnetic lifter

tool or a tool made from a large binder clip spring. See Pictures 2

and 3 below.

3. Rotate rear wheel to align timing marks on the primary cam chain.

4. Remove the primary chain tensioner by removing the two

retaining bolts and install sprocket locking tool.

5. Remove the crank sprocket bolt and flat washer.

6. Remove rear cam sprocket bolt and flat washer.

7. Remove sprocket locking tool.

8. Gently pry off crank sprocket and rear cam sprocket.

3

Cam

Intended Displacement

Intended Compression Ratio

551

88–106

9.0–10.0

557

96-103

9.6-10.0

570

88–106

9.0–10.0

583

88–106

9.0–10.0

585

88–106

9.2–10.5

625

95+

10.0–10.75

635

106-124

10.2-10.8

640

95+

10.5–11.5

675

120+

11+

HP103

103

9.6-10.0

MR103

103

9.6-10.0

CAUTION

WARNING

Picture 2

Grind points

on each end

Picture 3