S&S Cycle 2006-Up Gear Drive Cams for Harley-Davidson Twin Cam 88 Engines User Manual

Page 6

6

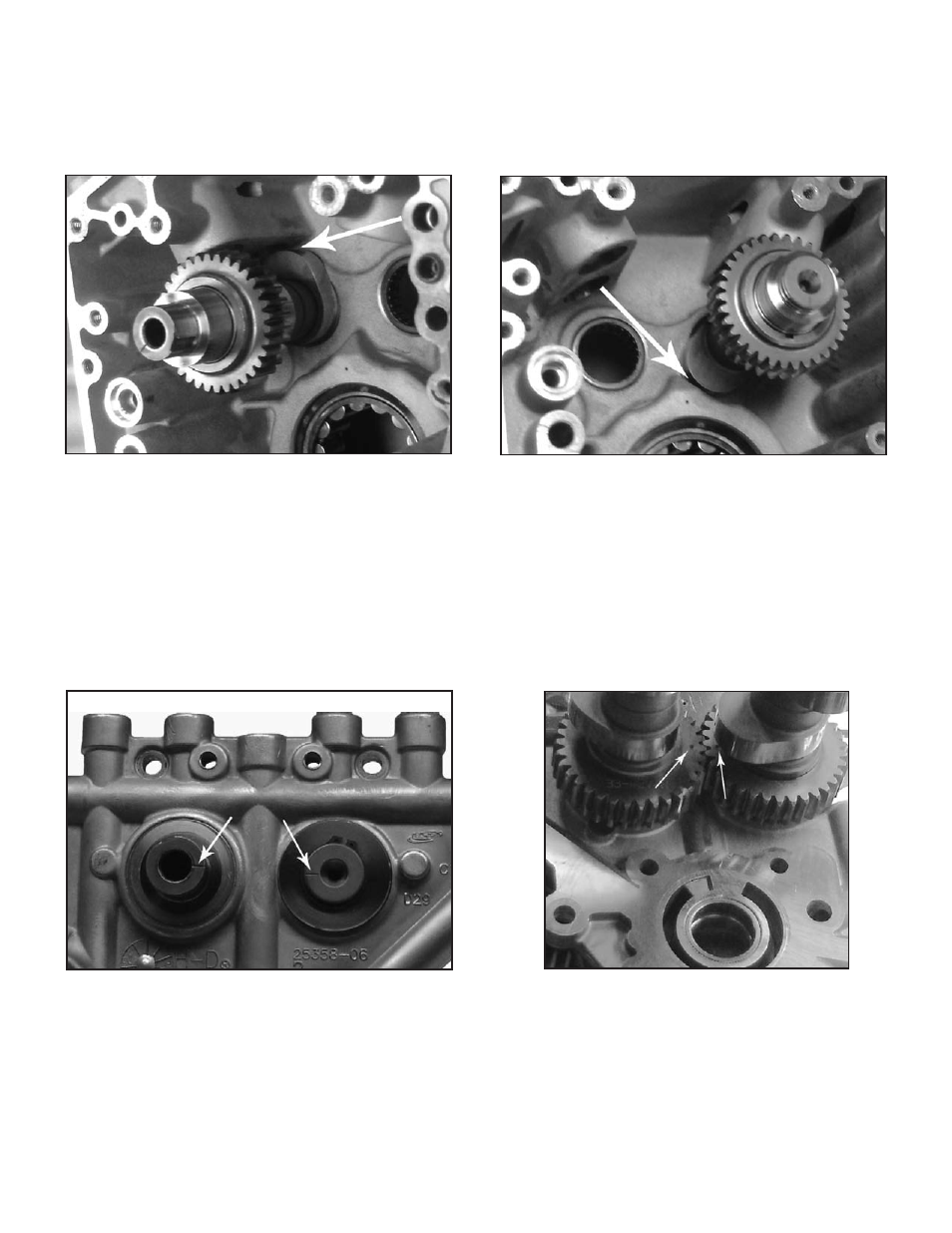

C- When using 585G, 625G, or 640G camshafts (33-5248, 33-5249, 33-5250) clearance between the pinion bearing boss and the rear cam lobe

must be checked. See Picture 7 & 8. Remove just enough material to provide .030” of clearance between the top of the cam lobe and the

pinion bearing boss when the camshafts are rotated in the inner needle bearing. Also check clearances between the cam lobe and the

tappet guide bosses. To avoid contamination of the engine with chips, we recommend that all holes in the gear case be taped off with duct

tape and that the gear case be thoroughly cleaned with parts cleaner or solvent after clearancing is performed.

Picture 8

Picture 7

D- Apply assembly lube to the outer races of the cam and the bearing bore of the support plate. Slide the S&S® front cam into place.

E- Install the .110” washer on the other side of the support plate over the front cam.

F- Install a new loaded retaining ring onto the end of the front cam to secure it in place.

NOTE: Before reinstalling the cam support plate make sure the oil pump o-rings are in good condition and remain in place during following procedure.

Replace worn or damaged o-rings if necessary.

G- Apply a thin layer of assembly lube to the rear cam journal, lobe surfaces, and inner bearing surfaces.

H- Slide the rear cam into place aligning the two timing marks on the back of the cam gears. See Picture 9a.

Picture 9

Picture 9a