Operation – MacDon 5020 Mower Conditioner User Manual

Page 28

28

OPERATION

REEL POSITION (continued)

NOTE: The reel must be adjusted equally on both

sides, both horizontally and vertically.

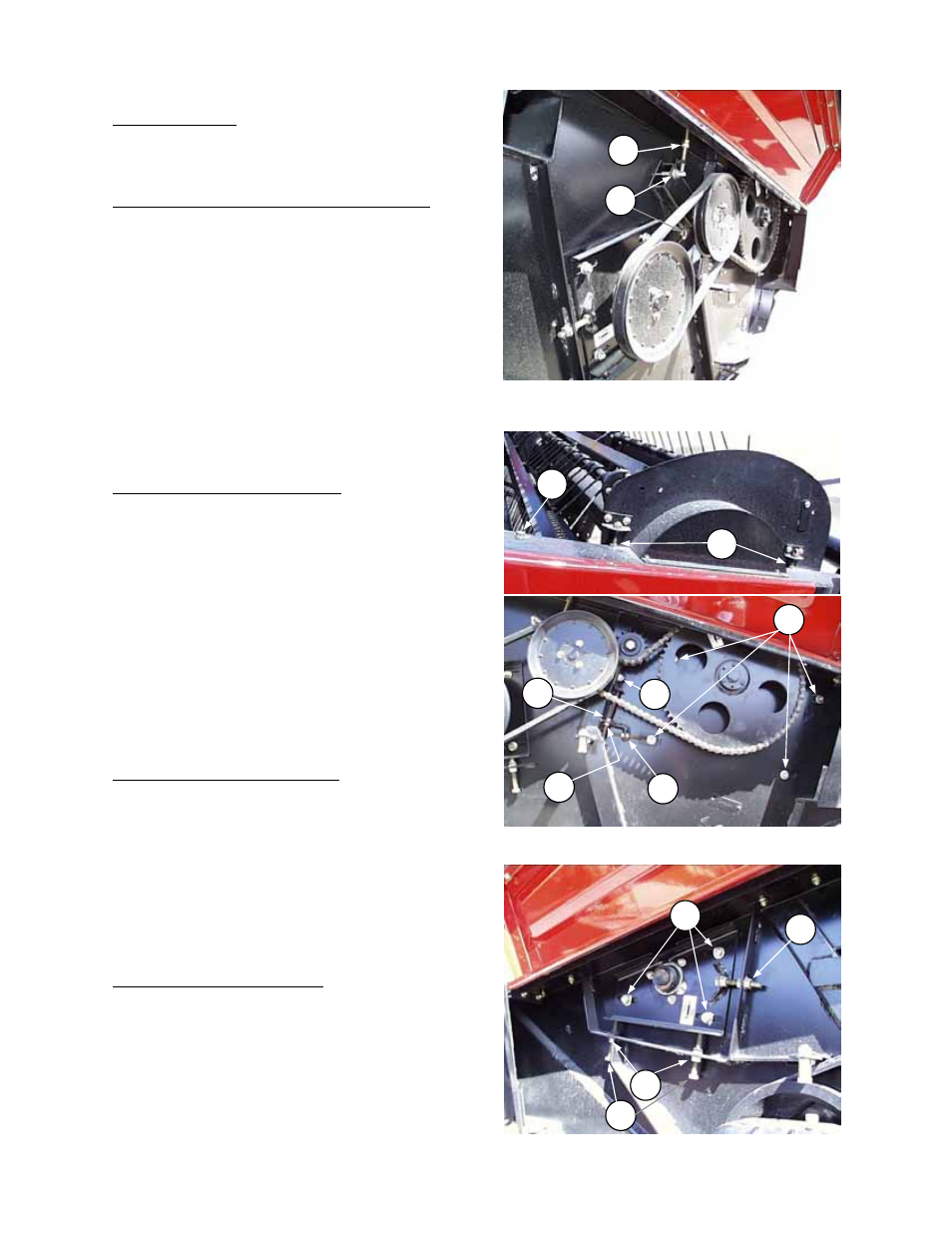

To adjust reel horizontal (fore-aft) position:

a. Loosen jam nut (A) on adjuster bolt and two

flange nuts (B) at reel drive arm. Loosen

adjuster bolt (C) to slacken belt

b. Loosen nut (D) and back off nut (E). Turn nut

(F) to move idler sprocket upward until reel

drive chain is loose.

c. Loosen nuts (G), three on left side, four on right

side.

d. Loosen jam nut on bolt (H), both sides, and

turn adjuster nuts to move reel fore or aft to

desired position. Tighten jam nut.

e. Tighten nuts (G).

f. Tighten belt first, then tighten chain. See

recommended tensions in Maintenance/

Service section.

To adjust reel vertical position:

a. Loosen jam nut (A) on adjuster bolt and two

flange nuts (B) at reel drive arm. Loosen

adjuster bolt (C) to slacken belt

b. Loosen nut (D) and back off nut (E). Turn nut

(F) to move idler sprocket upward until reel

drive chain is loose.

c. Loosen nuts (G), three on left side, four on right

side.

d. Loosen jam nuts (J) (left side only), and use

push bolts (K), two per side, to move reel up or

down to desired position. Tighten nuts (J).

e. Tighten nuts (G)

f. Tighten belt first, then tighten chain. See

recommended tensions in Maintenance/

Service section.

To adjust tine aggressiveness:

a. At right side of reel (cam end) only, loosen four

nuts (G).

b. Use push bolts (K) to rotate cam to desired

position. Viewed from right side, rotate cam

clockwise to obtain more aggressive tine

action.

c. Tighten nuts (G), then check that chain and/or

belt have not become over tight. Adjust to

recommended tension if required. See

Maintenance/ Service section.

After adjusting reel position:

a. Check that the reel rotates freely. Tines must

not contact auger, guards or ground.

b. Check that the reel is adjusted to the same

position on both sides. Reel tube should

appear parallel to header beam from both side

and front.

c. Check header float and adjust if required. See

"Header Flotation" in this section.

LOOSENING REEL DRIVE BELT –

RIGHT SIDE

A

B

REEL POSITION ADJUSTMENTS - LEFT SIDE

G

H

J

K

REEL POSITION ADJUSTMENTS - RIGHT SIDE

D

E

F

G

H

C

K