MacDon R85 Rotary Disc 13 Foot Self-Propelled Windrower Header User Manual

Page 159

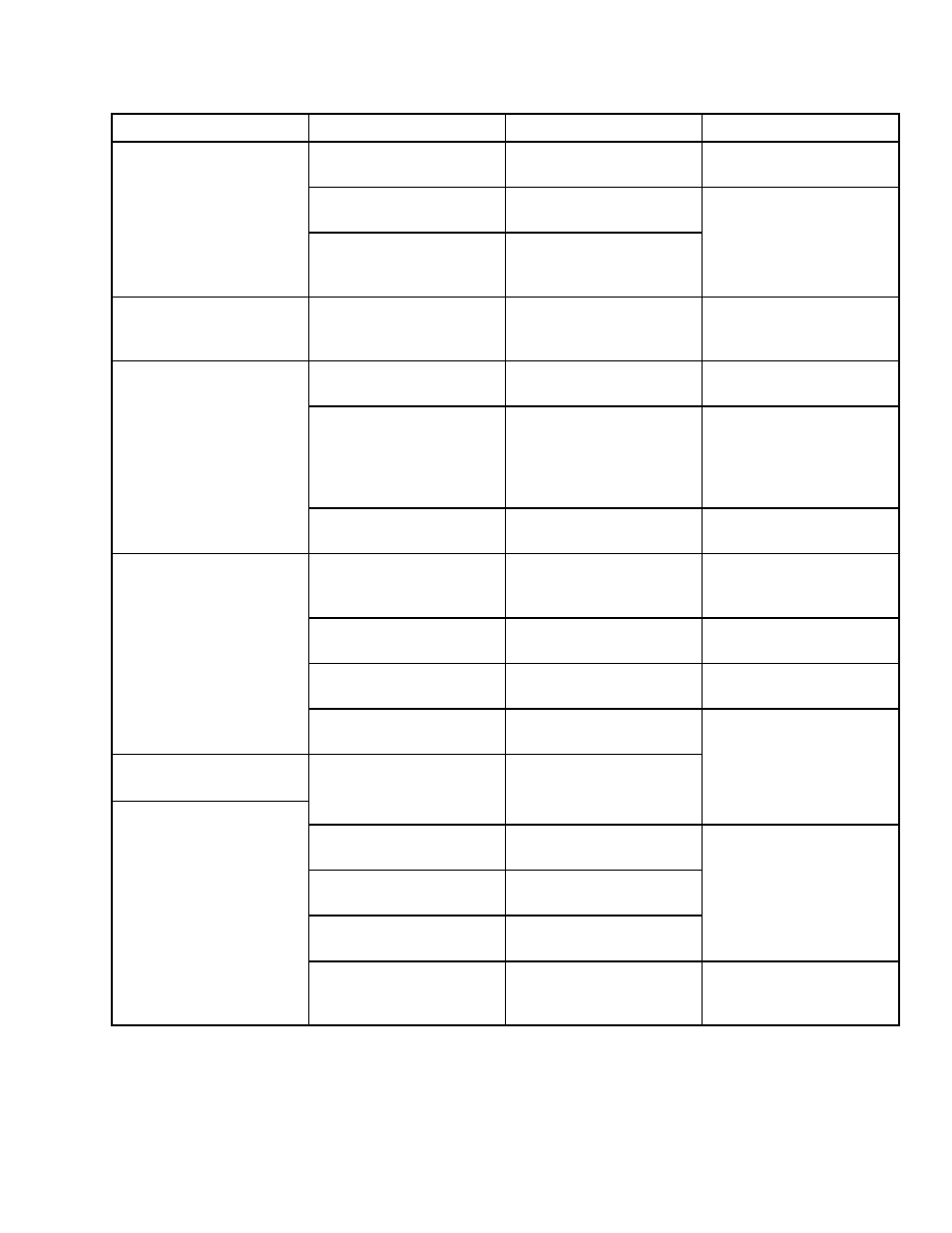

Symptom

Problem

Solution

Section

Header angle too steep

Reduce header angle

Crop residue and dirt

deposits on cutterbar

Clean cutterbar

Excessive wear of cutting

components

Mud on cutterbar

Remove mud from

cutterbar. Do NOT allow

mud to dry on cutterbar.

—

Machine pulling to one

side

Header dragging on one

end and pulling to that

side

Adjust header flotation on

both ends

6.1.1 Adjusting Header

Float, page 68

Belt not in proper groove

in pulley

Move belt to proper groove

Replacing the Conditioner

Drive Belt, page 140

Foreign object between

rolls

Disengage header and

stop engine. When

all moving parts are

completely stopped,

remove foreign object.

—

Breakage of conditioner

drive belt

Belt pulleys and idlers

misaligned

Align pulleys and idler

See MacDon Dealer

Mud on cutterbar

Remove mud from

cutterbar. Do NOT allow

mud to dry on cutterbar.

—

Hoses not connected

Connect hoses

5.7 Attaching the Header,

page 39

Faulty drive belt

Check drive belt pulleys

Inspecting the Conditioner

Drive Belt, page 138

Disc does not turn when

engaging header

Poor electrical connection

at pump solenoid

Check connection at

windrower

Header slows when going

uphill

Hydraulic oil level in

windrower is low

Add oil to windrower

reservoir

See windrower operator’s

manual

Defective hydraulic motor

Repair/replace hydraulic

motor

Defective hydraulic pump

in windrower

Repair/replace pump

Defective relief valve in

windrower

Repair/replace relief valve

See MacDon Dealer

Header runs while

unloaded, but slows

or stops when starting to

cut

Cold oil in hydraulic drive

system

Reduce ground speed

until oil reaches operating

temperature

169455

151

Rev. E