Unloading & assembly – MacDon 922 User Manual

Page 71

Form # 46620

Issue 01/06

69

UNLOADING & ASSEMBLY

INSTALL SKID SHOES OR GAUGE ROLLERS

NOTE: Before lowering header, install either

adjustable skid shoe or gauge roller option at

cutterbar. Installation instructions are packaged

with the option kit.

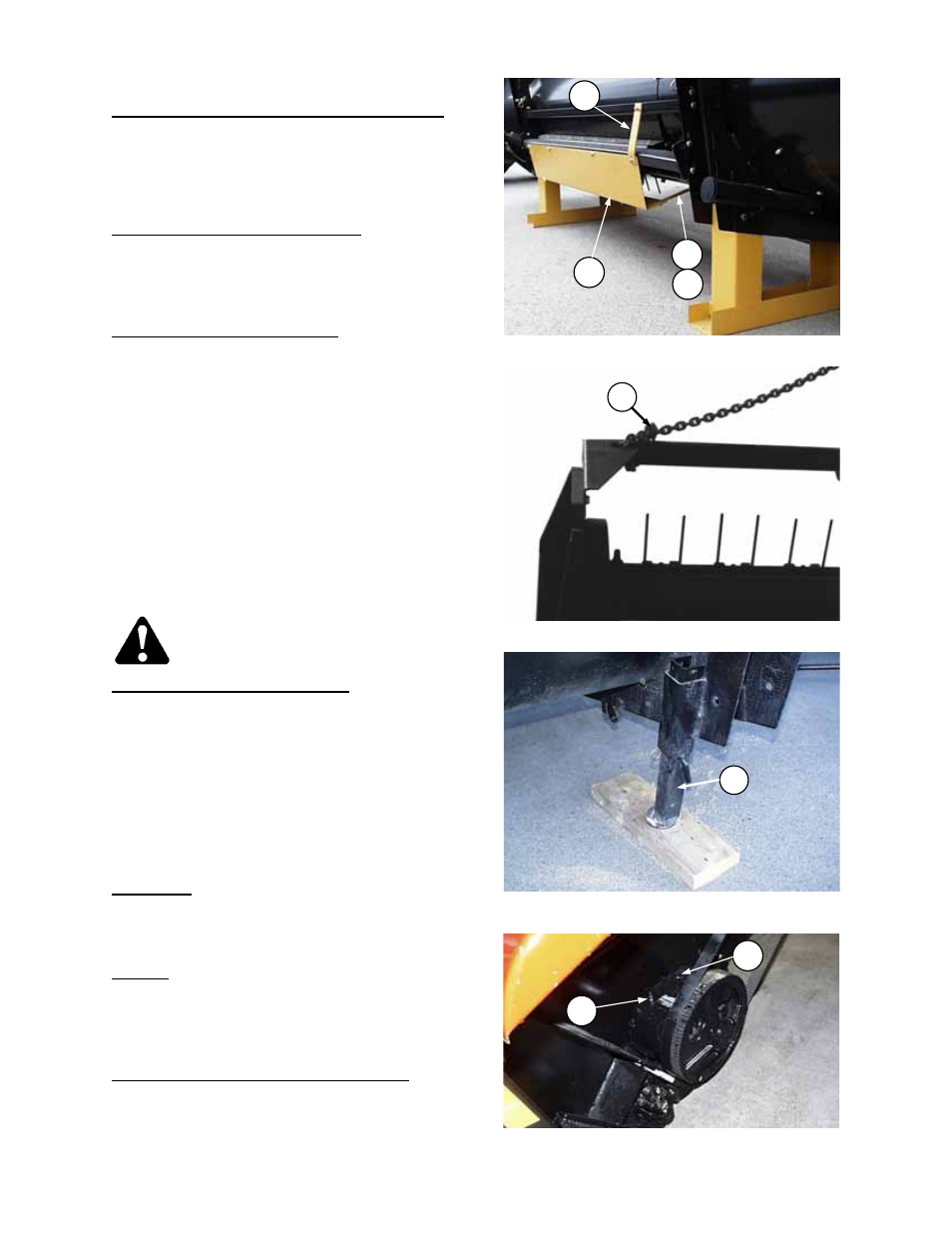

REMOVE LIFT PAN AND BRACES

Before lowering header, remove lift pan (B), two

vertical braces (C), and brace (D). (Model 933

Header not exactly as shown.)

LOWER HEADER TO GROUND

NOTE: Before lowering header, remove linkage

pins from header legs.

1. Drive lifting vehicle to approach header from its

"underside".

2. Attach chain (A) to both ends of lean bar as

shown.

IMPORTANT: See "Chain Requirements" in

this section for minimum chain specifications.

Also, chain length must be sufficient to provide

a minimum 48 inches (1220 mm) vertical

distance between forks and lean bar.

3. Raise lifting apparatus to take some of the

weight off shipping stands and back up

SLOWLY to lower the header.

CAUTION: Stand clear when

lowering, as machine may swing.

SET HEADER SUPPORT STAND

1. Remove chain and move lifting vehicle to rear

of header.

2. Attach chain to center link anchor on frame

tube. Raise rear of header and lower header

stand into position (E).

NOTE: In soft conditions use a 2x4 block

under stand.

3. Lower header onto stand. Remove yellow

shipping stands from header legs.

LEAN BAR

Lean bar is fully retracted for shipping. Reposition

lean bar to an appropriate height. See "Lean Bar

Position" in Operation section.

LIGHTS

Rotate lights from shipping position to field

position.

NOTE: Do not overtighten mounting hardware –

lights must pivot out of the way of obstructions.

REPOSITION WOBBLE BOX BREATHER

Swap positions of plug (F) and breather (G) at

wobble box to position breather in rear hole.

HEADER STAND – LOWERED

& SHIPPING STANDS REMOVED

E

LOWERING HEADER

A

REMOVE LIFT PAN & BRACES

B

C

D

(2)

REPOSITION WOBBLE BOX BREATHER

F

G