Maintenance/service – MacDon 922 User Manual

Page 46

Form # 46620

Issue 01/06

44

MAINTENANCE/SERVICE

SICKLE AND SICKLE DRIVE

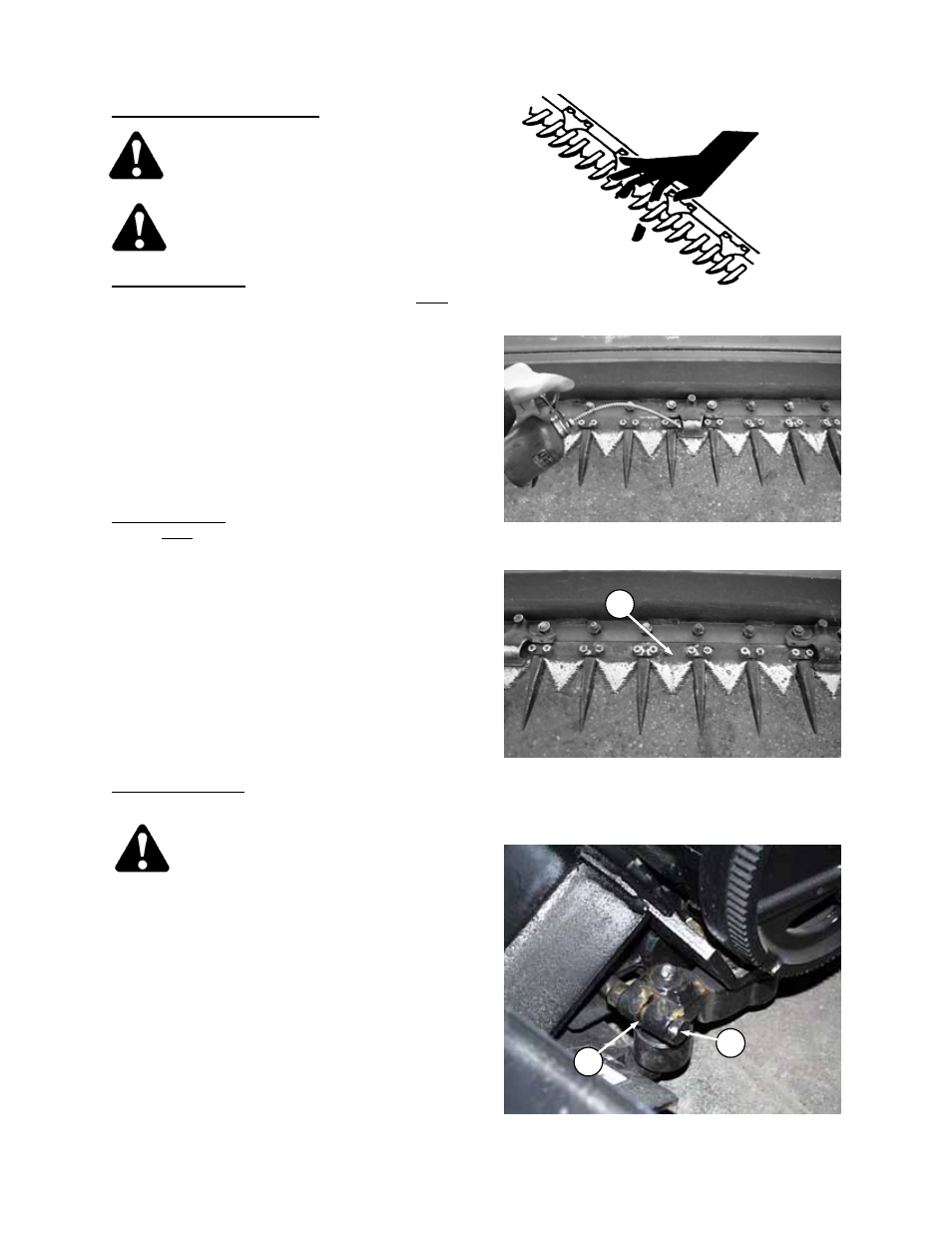

WARNING: Keep hands clear of the

area between guards and sickle at all

times.

CAUTION: Wear heavy gloves when

working around or handling sickles.

Sickle Lubrication

Apply SAE 10 or equivalent light weight oil daily

(one or two drops per section) along entire length

of sickle.

NOTE: Do not oil sickle if operating in sandy

conditions. Oil will cause sand to adhere to sickle

components, resulting in excessive wear.

Units with stub guards - Keep adjuster screws and

top guard adjuster bar well-lubricated, especially

before storage to prevent corrosion.

Sickle Sections

Check daily that sections are firmly bolted to the

sickle back and are not worn or broken. Replace

as required.

To replace sickle section:

1. A worn or broken sickle section (A) can be

replaced without removing sickle from

cutterbar.

2. Remove lock nuts and lift section off of bolts.

IMPORTANT: Do not mix heavy and light

sickle sections on same sickle.

3. Clean any dirt off of sickle back and position

new sickle section on bolts. Secure with lock

nuts.

To Remove Sickle

WARNING: Always stand to rear and

grasp rear edge of sickle during

removal to reduce risk of injury from

cutting edges. Wear heavy gloves

when handling sickle.

1. Clean area around sickle head. Stroke sickle

to its outer limit and remove bolt (C).

2. Insert screwdriver in slot (B) and pry up on

sickle head pin to free sickle.

3. Stroke pitman arm to clear bearing in sickle

head. Insert sickle head pin in sickle head to

shield bearing from dirt.

4. Wrap a chain around sickle head and pull

sickle out.

5. If sickle is not being immediately reinstalled,

cover sickle head to shield bearing from dirt.

KEEP HANDS AWAY FROM SICKLE

BOLT-ON SECTIONS

A

OIL SICKLE DAILY EXCEPT

IN SANDY SOIL

REMOVING SICKLE

C

B