Precision Turbo and Engine BigStuff3 GEN3 Powertrain Controller Ignition Setup Tutorial User Manual

Page 9

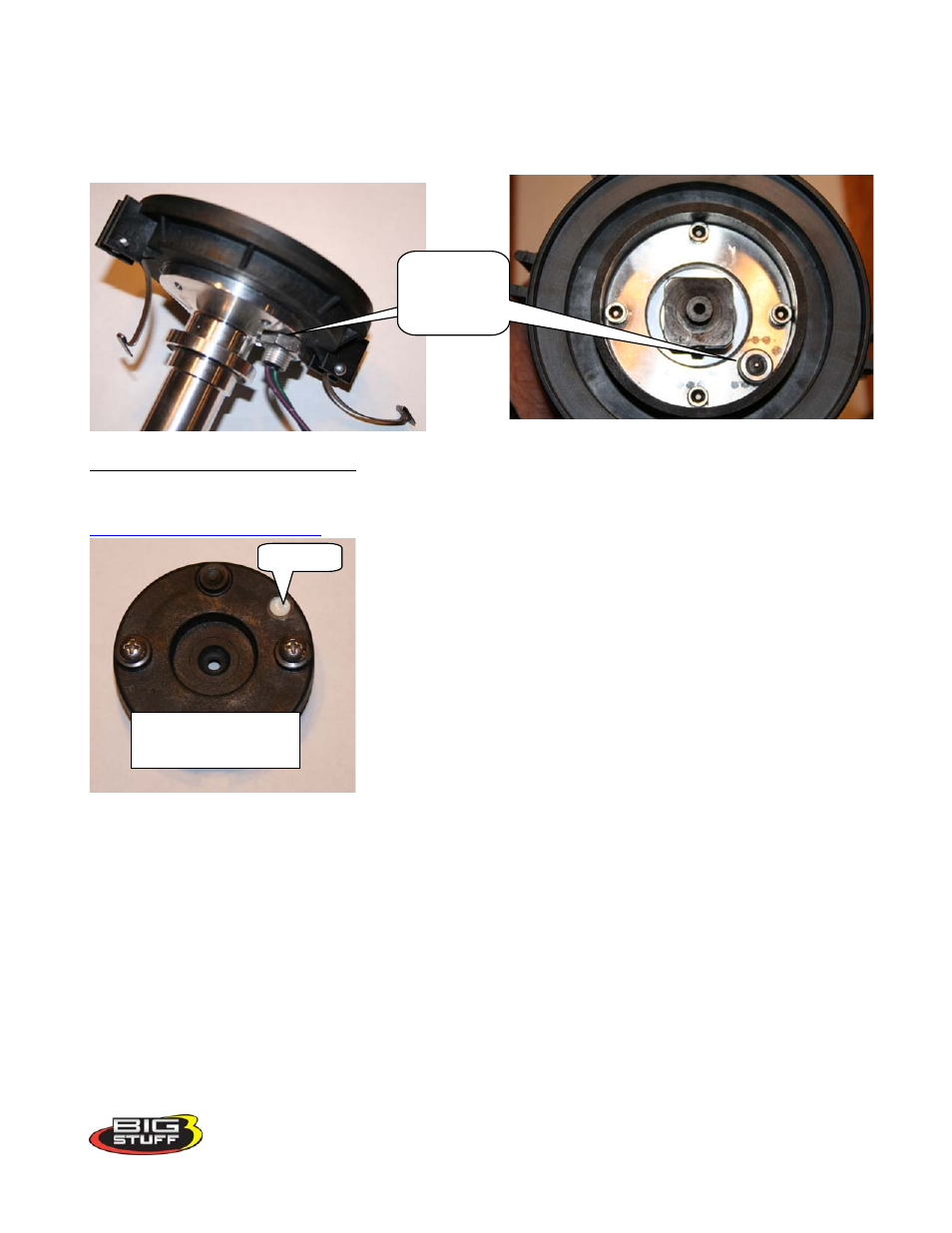

MSD Cam Sync Drive

Shown below is MSD’s cam sync distributor, part number 2340.

Inductive

pick-up

(sensor)

Installing the Cam Sync Distributor

The cam sync (signal) needs to occur 10

o

– 20

o

before the “Crank Reference” angle (see

on page 25 ). For example, if the “Crank Reference” angle is set to

45

o

BTDC (number 1 cylinder, compression stroke), the cam

sync should be installed between 55

o

and 65

o‘s

BTDC.

Magnet

Start by rotating the engine to the desired cam sync position (55 –

65

o

BTDC #1 Comp). Next remove the distributor cap and rotor.

While aligning the magnet with the Inductive Pick-Up (IPU)

sensor, drop it into the engine.

Note: Install the Cam Sync Distributor making sure that it is

installed in the engine in an orientation that allows the plug wires

to be easily routed to their respective cylinders and that the leads

(wires from the pickup) can be easily connected to the main wire

harness. Make sure the distributor is seated fully. “Bump” the engine to engage the oil pump drive.

Once fully seated, rotate the engine back to the desired cam sync position (55 – 65

o

BTDC), then

realign the magnet with the Inductive Pick-Up (IPU) sensor and tighten the base down.

Magnet carrier. Rotor

attaches to this piece

Next you’ll need to check/verify your rotor phase. Rotate the engine now to the timing desired for max

power (20

o

for boosted engines) note where the rotor is in relation to the distributor cap terminal. It

should be directly across. If not, use an MSD adjustable rotor or if space allows, an MSD “Cap-a-

Dapt” to correct the rotor phase. If space does not allow for a “Cap-a-Dapt” or the adjustable rotor did

not provide adequate phasing you will need to reposition the magnet in the magnet carrier as described

below.

8