Reluctor repositioning calculations – Precision Turbo and Engine BigStuff3 GEN3 Powertrain Controller Ignition Setup Tutorial User Manual

Page 25

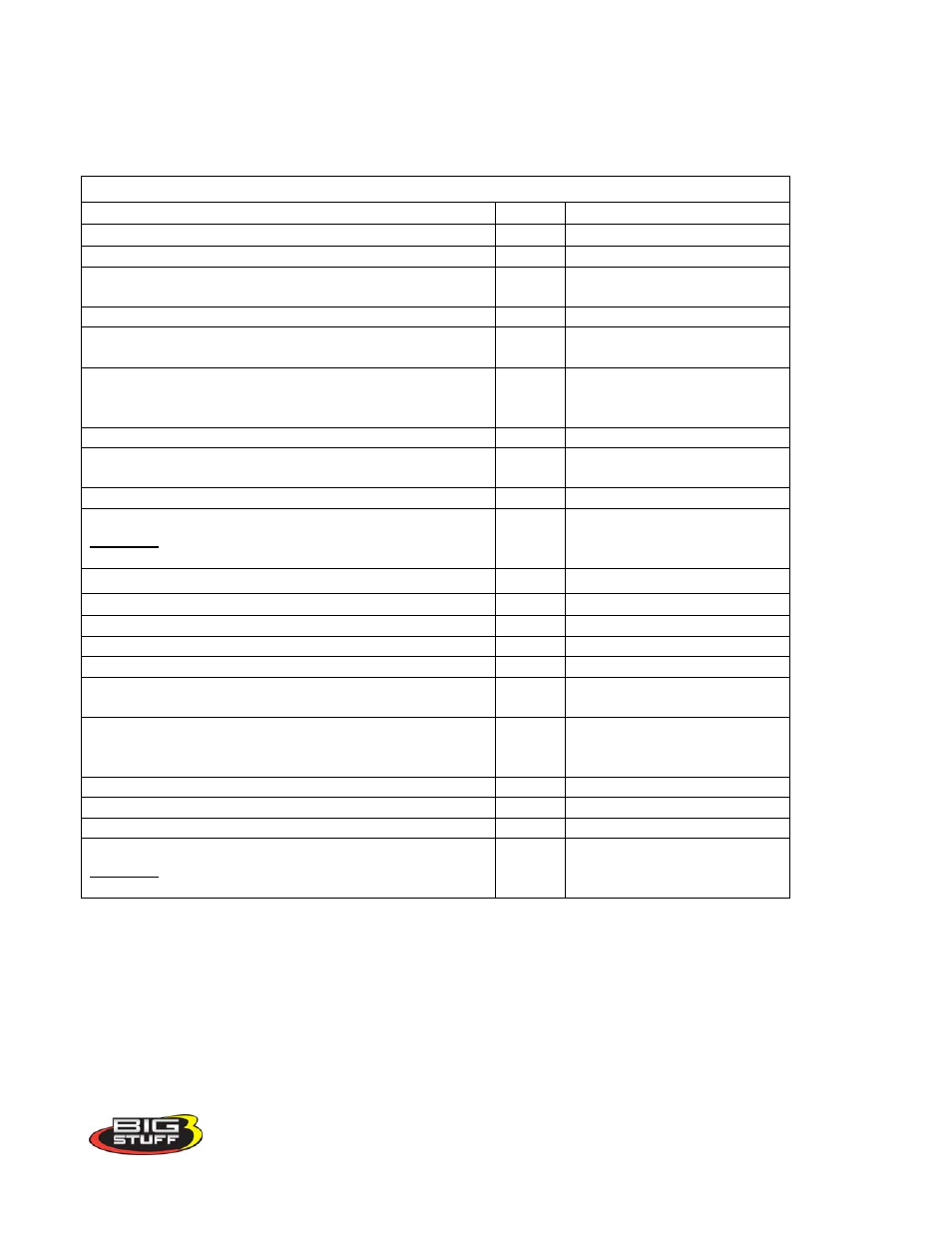

24

For example, with the Crank Reference set to 50

o

BTDC, the rotor needs to be retarded by 30

o

(crankshaft degrees) to achieve good rotor phase for a desired advance of 20

o

. The table below

outlines how this number was derived.

Reluctor Repositioning Calculations

Normally Aspirated Engine

BTDC

Maximum Timing Advance Engine will See (high speed

light load)

45

o

Plus 5

o

timing advance (buffer for ECU)

5

o

Equals Crank Reference (angle) Value Inputted Into

BigComm Software

50

o

Cam Sync - Degrees Need Before Crank Reference

+15

o

Cam Sync and Crank Angle

position cannot be the same

or the engine will not run.

Equals Cam Sync signal Position

65

o

Less Total Timing Advance Engine Will Operate under at

Peak Power

-38

o

Want best rotor phase here!

Equals Total Degrees (Crankshaft)

27

o

Total Degrees (Camshaft) the reluctor needs to be

advanced on the distributor shaft for rotor and cap

terminal to be “in-phase” at peak power.

14

o

Convert Crank Degrees to

Cam by dividing by 2

Boosted Engine

Maximum Timing Advance Engine will See

40

o

Plus 5

o

timing advance (buffer for ECU)

5

o

Equals Crank Reference (angle) Value Inputted Into

BigComm Software

45

o

Cam Sync - Degrees Needed Before Crank Reference

+15

o

Cam Sync and Crank Angle

position cannot be the same

or the engine will not run.

Cam Sync signal Position

60

o

Less Total Timing Advance Engine Operate at

-20

o

Want best rotor phase here!

Total Degrees (Crankshaft)

40

o

Total Degrees (Camshaft) the reluctor needs to be

advanced on the distributor shaft for rotor and cap

terminal to be “in-phase” at peak power

**20

o

Convert Crank Degrees to

Cam by dividing by 2

**If the number of degrees that the reluctor needs to be repositioned on the distributor shaft is more

than 10

o

, an adjustable rotor may need to be used in conjunction with repositioning the reluctor. Hand

modifications like adding a pin slot at 20

o

, may also need to be made to the reluctor. If hand

modifications are required, the new pin slot needs to be the same width and depth as the original slot so

that the reluctor does not move!

The following paragraphs explain how to reposition the reluctor on the distributor shaft of a MSD Pro-

Billet distributor so that cap and rotor are in-phase at peak power.