Generator start-up procedure (manual), Figure 30. voltage adjust control knob, Figure 31. ammeter (no load) – Multiquip DCA20SPXU2 User Manual

Page 32: Figure 32. oil pressure gauge, Figure 33. coolant temperature gauge, Figure 34. engine tachometer gauge, Figure 36. ammeter (load)

page 32 — dCa20spxu2 servpro

®

• operation and parts manual — rev. #0 (09/23/13)

5. If the voltage is not within the specified tolerance use

the voltage adjustment control knob (Figure 30) to

increase or decrease the desired voltage.

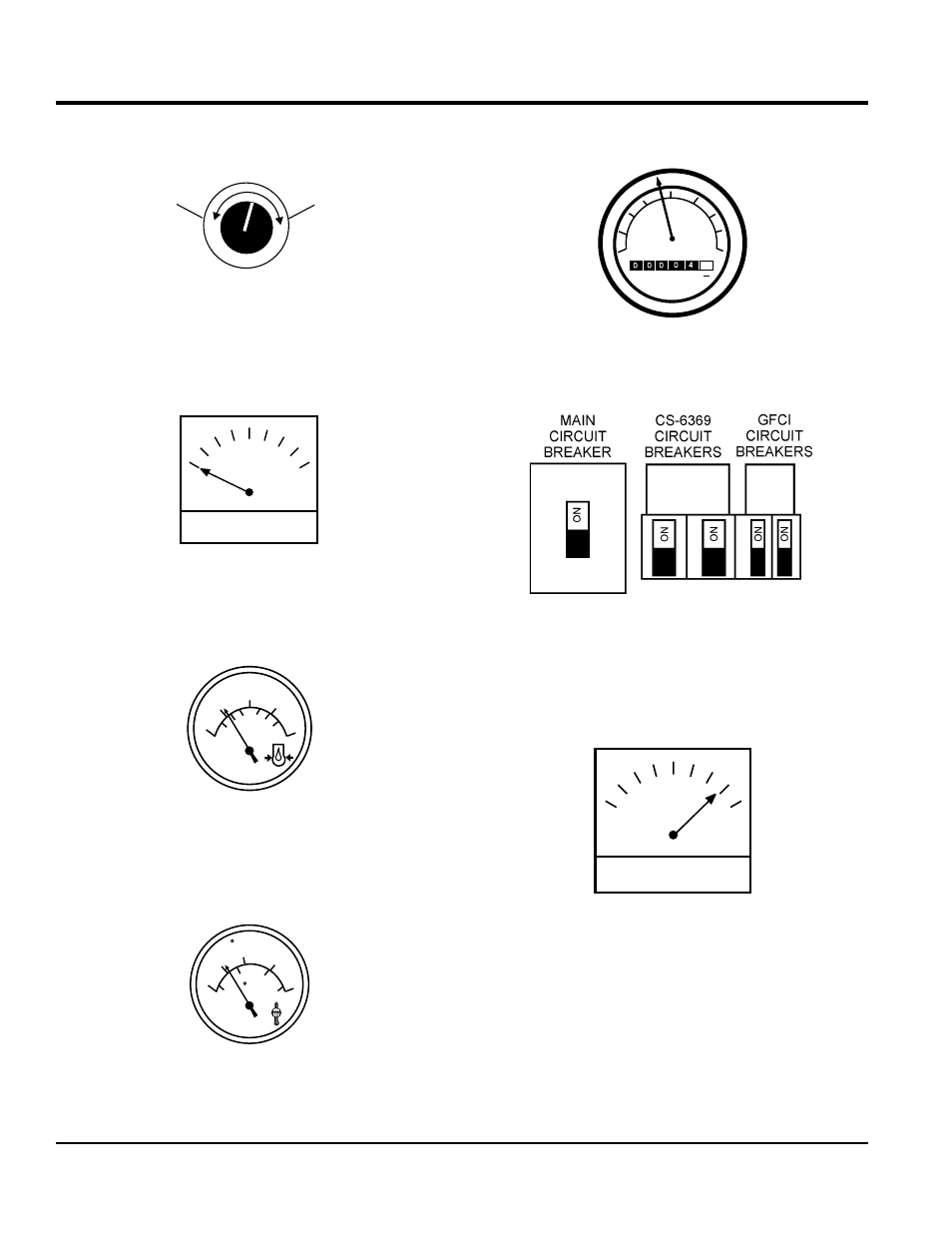

Figure 30. Voltage Adjust Control Knob

6. The ammeter (Figure 31) will indicate

zero amps with

no load applied. When a load is applied, the ammeter

will indicate the amount of current that the load is

drawing from the generator.

Figure 31. Ammeter (No Load)

7. The engine oil pressure gauge (Figure 32) will indicate

the oil pressure of the engine. Under normal operating

conditions the oil pressure is approximately 35 to 65

psi. (241~448 kPa).

Figure 32. Oil Pressure Gauge

8. The

coolant temperature gauge (Figure 33) will

indicate the coolant temperature. Under normal

operating conditions the coolant temperature should

be between 180°~221°F (82°~105°C) (

green zone).

Figure 33. Coolant Temperature Gauge

9. The

tachometer gauge (Figure 34) will indicate the

speed of the engine when the generator is operating.

INCREASE

DECREASE

A

50

75

100

0

25

1

2 3 4 5

6

bar

OIL

PRESS

psi

DATCON

150

180

240

100

130

40

C

WATER

TEMP

DATCON

60

80

110

F

Under normal operating conditions this speed is

approximately 1800 RPM’s.

Figure 34. Engine Tachometer Gauge

10. Place the

main, g.F.C.i., and aux. circuit breakers

(Figure 35) in the

on position.

.

Figure 35. Main, Aux. and GFCI

Circuit Breakers (ON)

11. Observe the generator’s ammeter (Figure 36) and

verify it reads the anticipated amount of current with

respect to the load. The ammeter will only display a

current reading if a load is in use.

Figure 36. Ammeter (Load)

12. The generator will run until manually stopped or an

abnormal condition occurs.

20

25

30

10

40

TACH

HOURS

RPM X 100

8

1

10

0

35

5

15

0

0

0

0

4

A

generatOr start-up prOceDure (ManuaL)