C-4 finisher trowel — maintenance – Multiquip C42H User Manual

Page 28

PAGE 28 — C-4 FINISHER WALK-BEHIND TROWEL— PARTS & OPERATION MANUAL — REV. #0 (07/24/02)

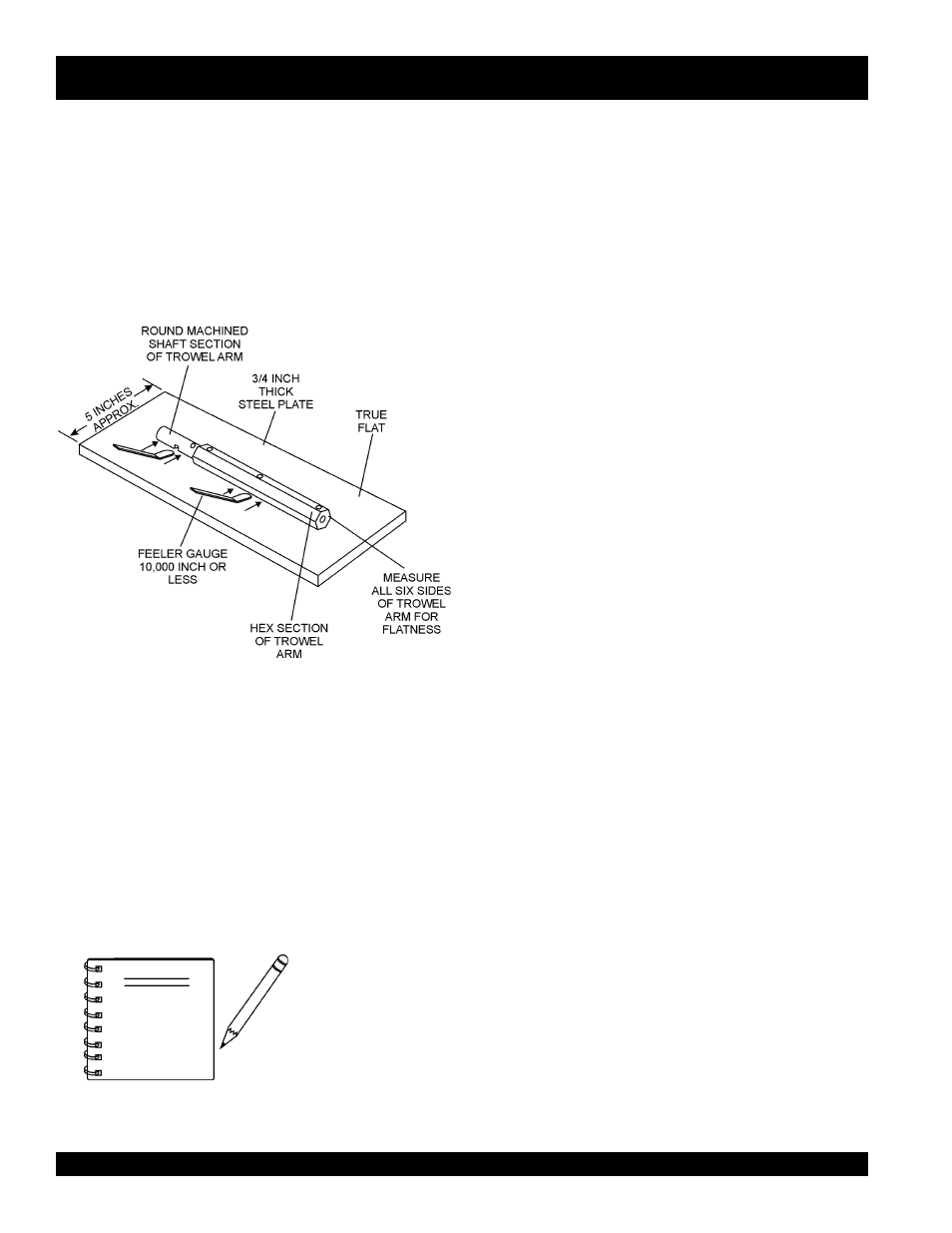

Trowel Arm Flatness Test

1. Using a piece of 3/4 inch thick steel plate or any surface which

is

true

and

flat

, check all

six sides

of each trowel arm for

flatness.

2. Check each of the six sides of the trowel arm (hex section

only) using a ten thousands of an inch (max.) feeler gauge

(Figure 28) between the flat of the trowel arm and an

ex

-

tremely flat

test surface.

3. If the trowel arm is found to be

uneven

or

bent

, replace the

trowel arm. A bent trowel will not allow the trowel to operate

in a smooth fluid rotation.

4. Next, check each of the six sides of the round machined shaft

section of the trowel arm. Each section should have the

same

clearance

between the round of the trowel arm shaft and the

test surface.

Figure 28. Trowel Arm Flatness Test

C-4 FINISHER TROWEL — MAINTENANCE

Trowel arms can be

damaged by rough

handling or by striking

exposed plumbing or

forms while in operation.

ALWAYS look-out for

objects which might

cause damage to the

trowel arms.

Re-Assembly

1. Clean and examine the

lower wear plate

,

thrust collar

and

thrust collar bushing

. Examine the entire spider assembly.

Wire brush any concrete or rust build-up. If any of the spider

components are found to be damaged or out of round,

replace them.

2. Insert all trowel arms (4) into spider plate.

3. Lock trowel arms in place by tightening the hex head zerk

grease fittings (4) and allen head screws (2).

4. Re-install the blades back onto the trowel arms.

5. Reinstall lower wear plate,

thrust collar

and

thrust collar

bearing

in the

reverse order

that they were dis-assembled

onto the spider shaft. Make sure that there is little or no lateral

movement between the thrust collar and the spider shaft.

6. Carefully lift

the upper trowel assembly

, line up the key-

way on gear box main shaft and insert into spider assembly.

7. Lubricate all grease points (zerk fittings) with premium

"

Lithum 12"

based grease, conforming to NLG1 Grade #2

consistency.

NOTE