Operation – Multiquip LS-300P User Manual

Page 35

MAYCO LS300P CONCRETE PUMP • OPERATION MANUAL — REV. #0 (06/09/14) — PAGE 35

3. A

thumping sound (cylinder stroke) should be heard.

The thumping sound represents the number of strokes

per minute (volume) of the pump.

4. Scroll through the

digital readout screen with the

scroll switch to go to screen 7 (Figure 28). This screen

will show the volume in strokes per minute.

Figure 28. Strokes Per Minute Display

5. Let the pump cycle until the hydraulic oil temperature

(Figure 29) is approximately 50° to 60° F.

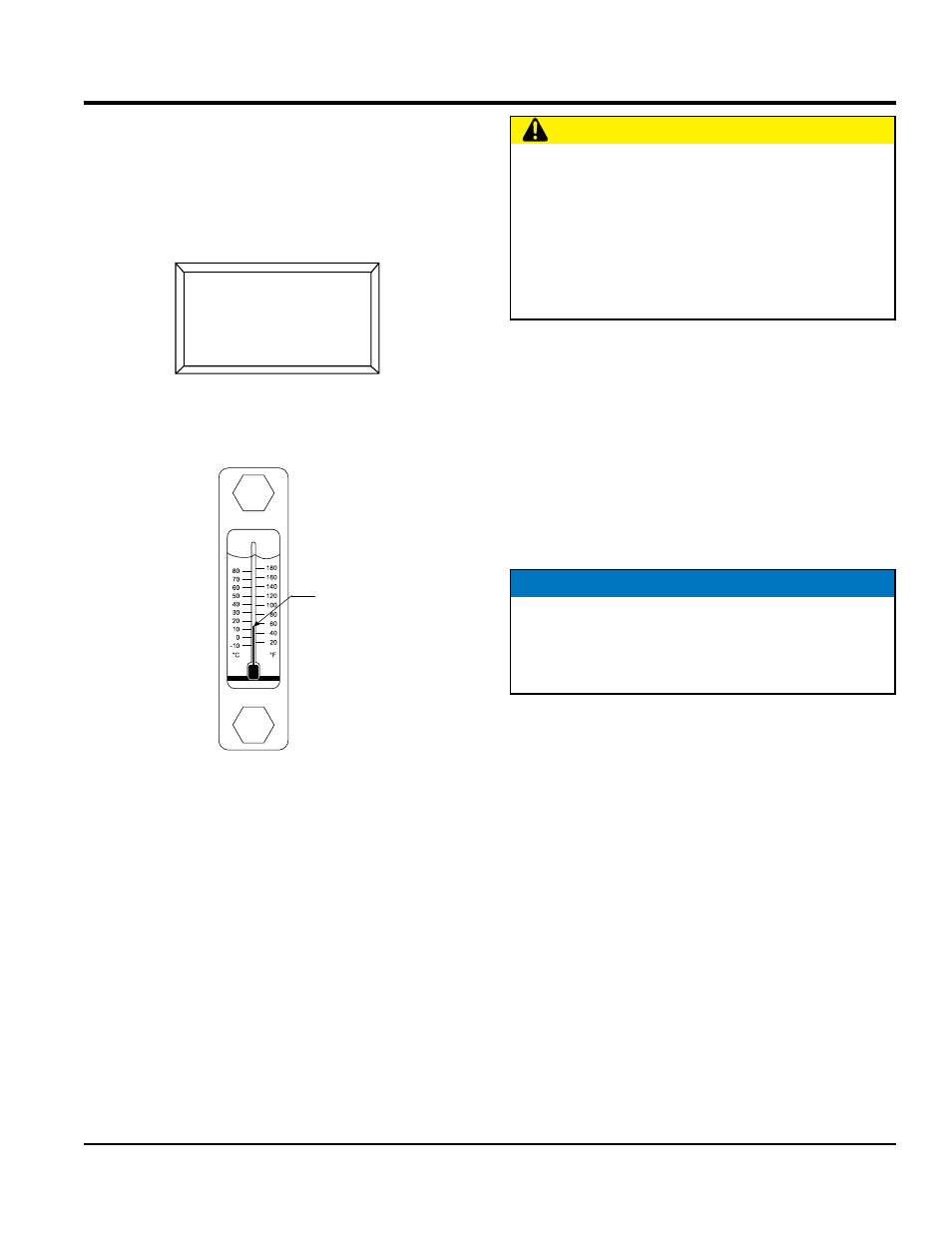

Figure 29. Hydraulic Oil Temperature Gauge

6. Rotate the Volume Control Knob (Figure 27) to the right

to increase the volume to 25-30 strokes per minute.

Place pump control switch in the center “

OFF” position.

Slowly discharge the concrete from the ready-mix truck

into the hopper and completely fill it.

Place pump control switch in the local “

ON” pumping

position. Keep the pump running continuously until

concrete is discharging at the end of the delivery

system. If the pumping operation suddenly stops with

no concrete discharging from the hose, a blockage

may have occurred. Immediately place the switch in the

“

OFF” position. Refer to Clearing Concrete Blockage

Section.

THROTTLE ON

STROKES: 100

STROKES/MIN 10.0

YDS/HR 0.0

7

HYDRAULIC OIL

TEMPERATURE

7. It is important that once the slurry procedure is

completed, and concrete is flowing through the hose,

DO NOT stop the pour until all the slurry is pumped

out and the concrete has reached the end of the hose.

The only time to stop the pump during the priming

procedure is if a blockage occurs.

8. If it is necessary to replace or add a section of delivery

system, after the initial lubrication procedure, wet the

inside area of the hose, pipe or elbow with 5 gallons of

water per 25 foot length, before adding it to the system.

CAUTION

HOSE/LINE BLOCKAGE

If hoses or lines are blocked for any reason, or if the

lines are kinked when starting up or during the pumping

cycle, the pump pressure could straighten out the kink

or force out the blockage. This rapid surge of material

could cause the lines to whip or move in a manner that

could cause injury to personnel.

NOTICE

When pumping long distance or pumping stiff mixes, you

can expect a drop in volume compared to shorter lines

and wetter mixes due to the change in valve efficiency

or cavitation.

OPERATION