General information – Multiquip C10PH8 User Manual

Page 14

PAGE 14 — C10SH8-PH8 CONCRETE MIXER • OPERATION AND PARTS MANUAL — REV. #0 (03/06/09)

GENERAL INFORMATION

APPLICATION

This mixer is only intended for the production of concrete.

The mixer must be used for its intended purpose and

is not suitable for the mixing of fl ammable or explosive

substances. The mixer must not be used in an explosive

atmosphere. Use Table 5 (Mixing Hints) as a guide when

mixing concrete for various applications.

POWER PLANTS

The Stow C10SH8 and C10PH8 mixers are powered by an

air-cooled, 4-stroke Honda GX240U1QA2 gasoline engine.

Refer to Table 2 for engine specifi cations.

HARDWARE

Check all hardware on the mixer before starting Periodically

inspect all hardware. Loose hardware can contribute to

early component failure and poor performance. Use Table

4 as general guideline when the torqueing of mixer

hardware is required. Remember to keep all mixer hardware

components tight.

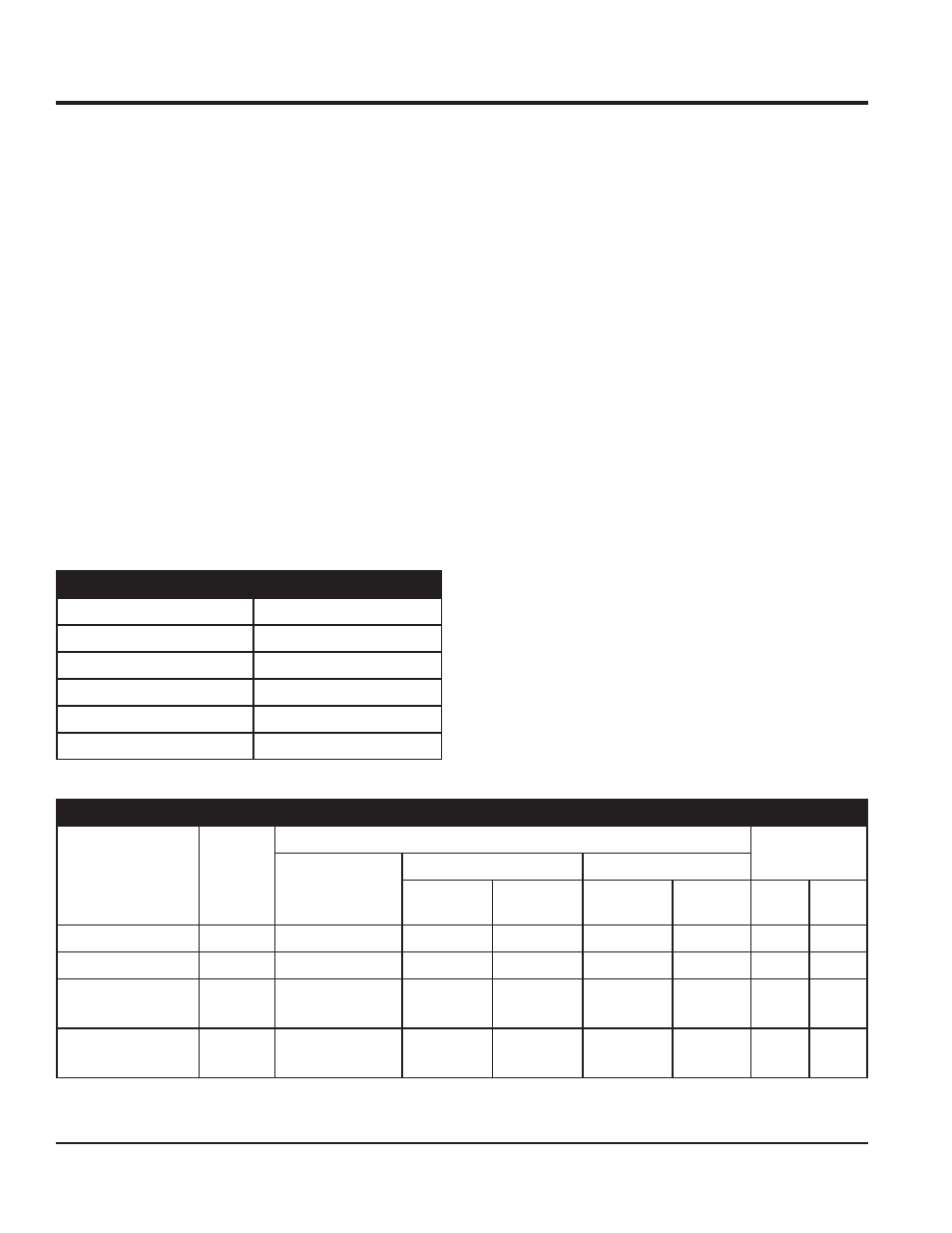

Hardware Torque Recommendations

Table 4.

Hardware Diameter

Torque (ft-lbs)

5/16-inch x 18

14

3/8-inch x 16

24

3/8-inch x 24

37

1/2-inch x 13

39

1/2-inch x 13 (Grade 8)

90

ENGINE MAINTENANCE

For basic engine maintenance, refer to the engine

maintenance section in this manual. For more detailed

engine maintenance information, refer to the Honda engine

owner’s manual supplied with the engine.

Mixing Hints

Table 5.

Applications

Mix

Ratios

Batch Quantities

Approx. Batch

Output

Cement 112

lbs. (50 Kgs.)

Bag

Sand

Stone

Cu. Ft.

Ltr

Cu. Ft.

Ltr

Cu.Ft.

Ltr

Most Ordinary

1:2:4

1/2 Bag

1-1/4

35

2-1/2

71

3

85

Foundations

1:3:6

1/3 Bag

1-1/4

35

2-1/2

71

2-3/4

78

Rough Mass

Concrete

1:4:8

1/4 Bag

1-1/4

35

2-1/2

71

2-3/4

78

Watertight Floors,

Tanks, Pits, Etc.

1:1-1/2:3

2/3 Bag

1-1/4

35

3

71

3

85