Daw-500s— welder/generator use, Caution – Multiquip DAW500S User Manual

Page 29

DAW-500S WELDER/A.C. GENERATOR — PARTS & OPERATION MANUAL — REV.#0 (07/19/01) — PAGE 29

DAW-500S— WELDER/GENERATOR USE

Duty Cycle

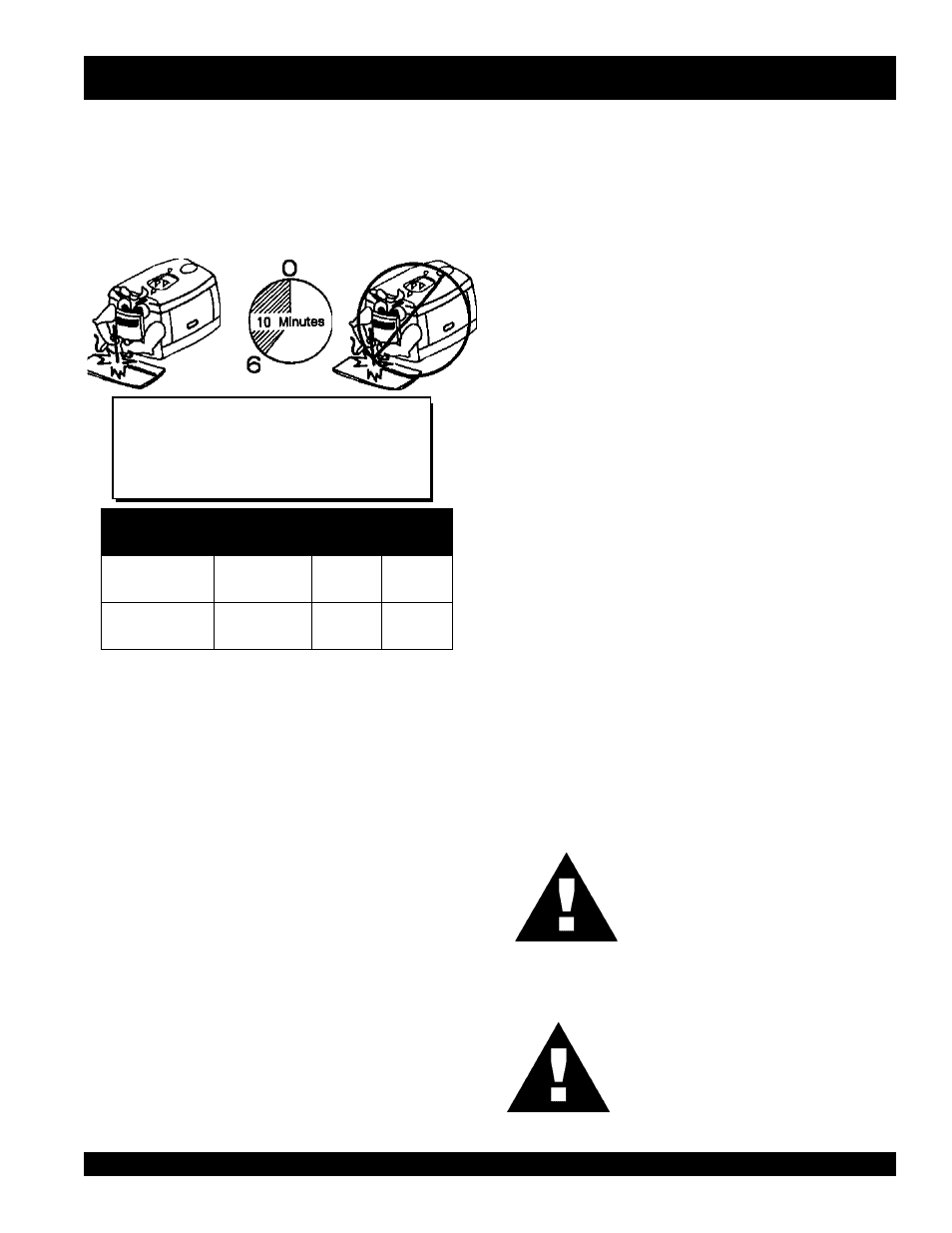

The welder is rated at 100% duty cycle at 350 amps. Duty

Cycle refers to the amount of time the user can weld and

how long the machine must rest. The duty cycle depends

upon the welding current being used. Select the appropriate

duty cycle from Table 14 to prevent overload.

CAUTION :

FIVE ESSENTIALS FOR PROPER

WELDING PROCEDURES

Besides the steady sizzling sound that a correct arc

produces, the shape of the molten pool and the move-

ment of the metal at the rear of the pool serve as a guide

in checking weld quality. In a correctly made deposit, the

ripples produced on the bead will be uniform and the bead

will be smooth, with no overlap or undercut.

1. Correct Electrode Size

The correct choice of electrode size involves consider-

ation of a variety of factors. Such as the type, position,

and preparation of the joint, the ability of the electrode to

carry high current values without injury to the weld metal

or loss of deposition efficiency. The mass of work metal

and its ability to maintain its original properties after

welding, the characteristics of the assembly with refer-

ence to effect of stresses set up by heat application, the

practicability of heat treatment before and/or after welding,

the specific requirements as to welding quality and the

cost of achieving the desired results.

2. Correct Current

If current on equipment is too high or too low, you are

certain to be disappointed in your weld. If too high, the

electrode melts too fast and your molten pool is large and

irregular. If too low, there is not enough heat to melt the

base metal and your molten pool will be too small, will pile

up, and look irregular.

3. Correct Arc Length

If the arc is too long or voltage too high the metal melts

off the electrode in large globules which wobble from side

to side as the arc wavers, giving a wide, spattered and

irregular bead–with poor fusion between original metal and

deposited metal.

If the arc is too short or voltage too low, there is not

enough heat to melt the base metal properly and the

electrode quite often sticks to the work. This gives a high,

uneven bead, having irregular ripples and poor fusion.

4. Correct Travel Speed

When your speed is too fast: your pool does not last long

enough, impurities and gas is locked in. The bead is

narrow and ripples pointed. When speed is too slow: the

metal piles up, the bead is high and wide, with a rather

straight ripple.

5. Correct Electrode Angle

The electrode angle is of particular importance in fillet

welding and deep groove welding. Generally speaking,

when making a filet weld, the electrode should be held so

that it bisects the angle between the plates and is

perpendicular to the line of weld. If under cut occurs in the

vertical member lowers the angle of the arc and directs

the arc toward the vertical member.

Always wear welding shield with correct

filter shade when welding. Improper use,

or looking directly at the arc will lead to

blindness.

e

l

c

y

C

y

t

u

D

.

4

1

e

l

b

a

T

)

%

(

e

l

c

y

C

y

t

u

D

0

0

1

0

8

0

6

)

s

p

m

A

(

t

n

e

r

r

u

C

s

s

e

l

r

o

0

5

3

0

0

4

0

5

4

The 450 amp, 60% duty cycle referenced in

Table 14 is for CV welding ONLY.

EXAMPLE:

CAUTION :

Use protective screens or barriers to

protect others from flash and glare; warn

others not to stare at the welding arc.