Daw-500s — controls and indicators – Multiquip DAW500S User Manual

Page 14

PAGE 14 —DAW-500S WELDER/A.C. GENERATOR— PARTS & OPERATION MANUAL — REV. #0 (07/19/01)

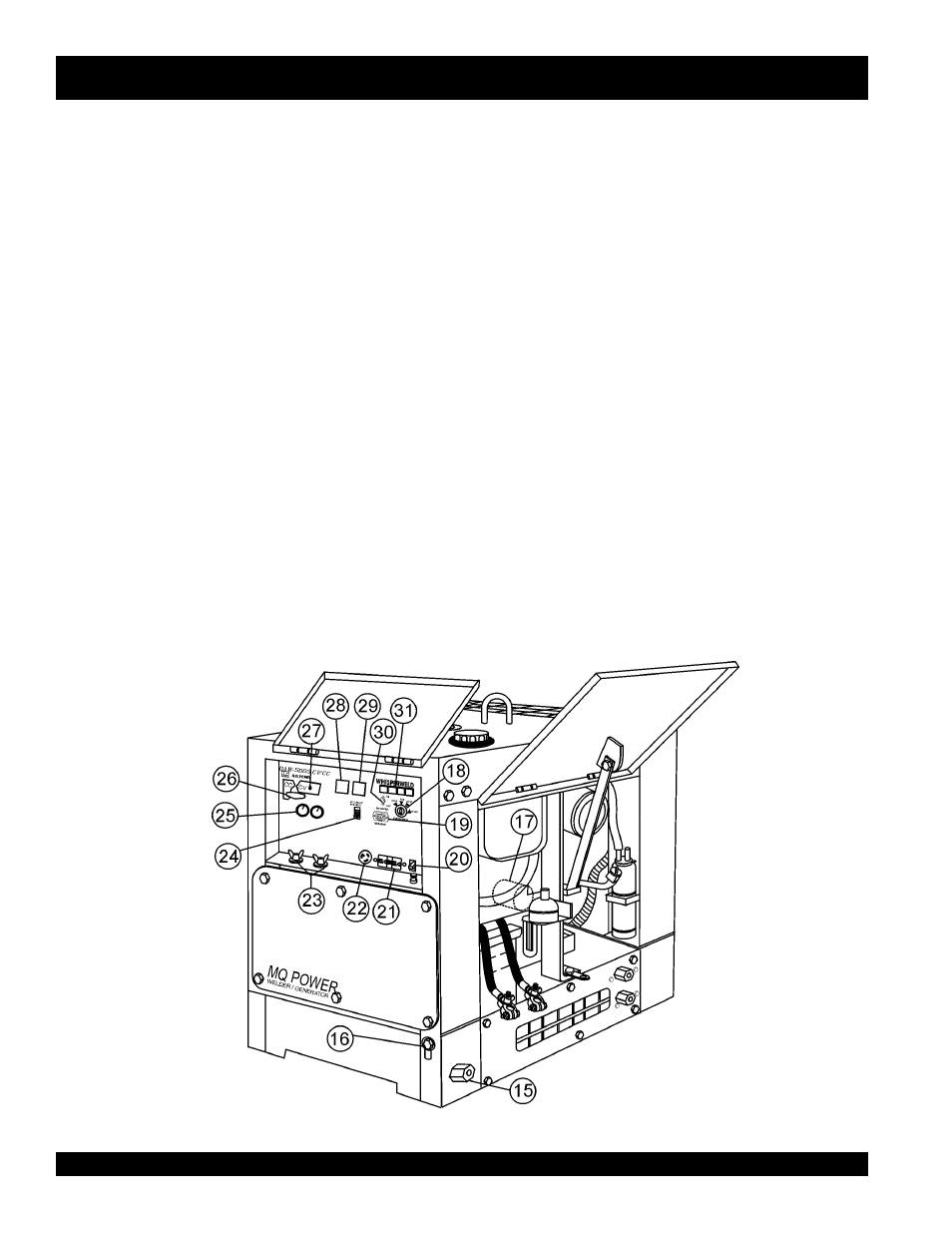

DAW-500S — CONTROLS AND INDICATORS

15. Fuel Drain Plug – Remove this plug to drain fuel from the

fuel tank.

16. Frame Ground Lug – Connect a ground strap between

this lug and a ground rod. Make sure the ground rod is

inserted deep into the ground to provide a good earth

ground. Consult with local Electrical and Safety Codes for

proper connection.

17. Oil Filter – Provides oil filtering for the engine.

18. Ignition Switch – With key inserted turn clockwise to start

engine.

19. Hour Meter – Indicates number of hours machine has

been in use or hours engine was run.

20. Circuit Protector Circuit Breaker – This single pole circuit

breaker provides circuit protection (120V @20 amps) for

the G.F.C.I. receptacle.

21. Receptacle G.F.C.I. – This receptacle provides 120 volts

output at 20 amps.

22. Receptacle – Provides 120 volts output at 25 amps.

23. Welding Output Terminals – Connect the welding cable

to this terminal. Select the appropriate polarities according

to the application. See Table 7.

! Low Oil Pressure

! High Water Temperature

! Electrical System Is Not Charging Properly

! Preheat Indicator

27. Sub-Selector Switch-This switch is used to select type of

welding and welding voltage needed. This switch will not

work in CC mode.

28. DC Voltmeter- Indicated the amount of voltage used during

welding in CV mode.

29. DC Ammeter- Indicates the amount of amperage being

used during welding in CC mode.

30. Idle Control Switch – Regulates the engine speed when

the welder/AC generator is under load.

31. Warning Lamp Display – Lights red when the following

conditions occur:

Figure 3. Controls and Indicators (con't)

24. Main Circuit Breaker – This single-pole circuit breaker

provides circuit protection (125V @25 amps) for the electric

parts assembly.

25. Current Control (CC) Voltage Control (CV) Adjustment

Knobs – Use these controls to adjust welding current and

voltage.

26. Welding Type (Wire/Stick) Selector Switch (CV/CC) –

Turn this selector switch to either the CV or CC for welding.

DO NOT turn this switch under load.