Troubleshooting (pump), Priming or pump flow problems – Multiquip MP200SDLSM Operation Manual User Manual

Page 53

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 53

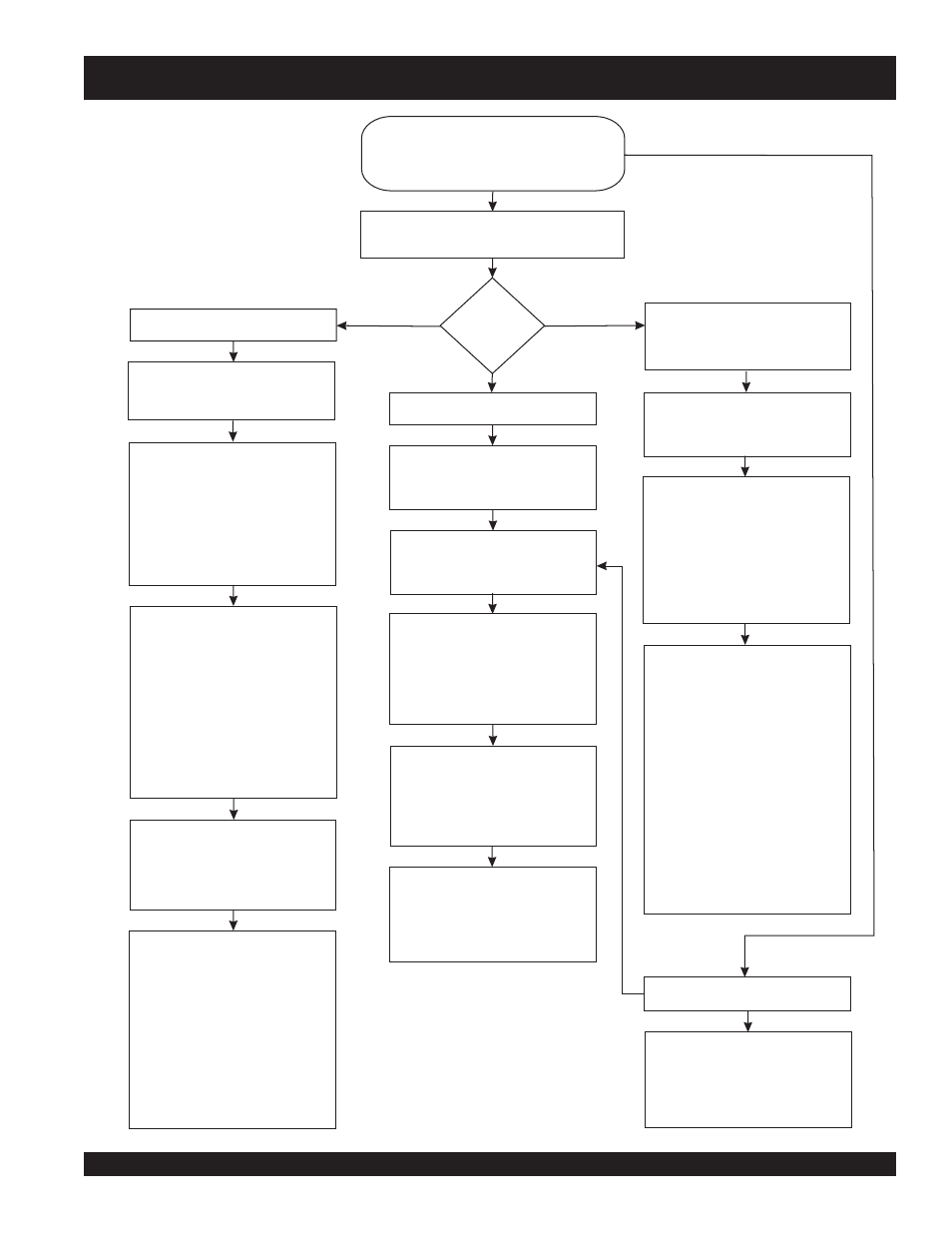

TROUBLESHOOTING (PUMP)

Priming or Pump

Flow Problems

Check for air discharge from the elbow on

the water fill tank. The cover must be on.

Air

Discharge?

Check vacuum gauge reading.

Check vacuum gauge reading.

High

No

Low

If low vacuum reading, vacuum

pump might not be producing

rated vacuum level.

Check the water level in the

hose below the fill cap. If level

is above half full on the hose,

check the vacuum pump

temperature and check for water

flow out of the vacuum pump

discharge hose. Check vacuum

pump hose for damage.

If the temperature and water flow

out of the vacuum pump is

normal, shut off the pump,

disconnect suction hose, do dry

vacuum test, and check vacuum

gauge. Check for air leaks

including at the pump seal. If the

oil level is low, add oil and redo

dry vacuum test. No oil could

indicate seal failure. Listen at the

seal oil fill cap for an air leak.

Check vacuum at vacuum pump

by disconnecting inlet hose. If

low, disassemble vacuum pump

and inspect.

If the vacuum pump water

temperature is high, or if there is

no water flow visible, clean the

filter in the water feed line. If a

filter is not installed, clean the

inlet orifice behind the vacuum

pump turbine with a wire. If the

problem persists, clean the

water reservoir by flushing with

clean water. A filter should be

added.

If the vacuum reading is 20” or

more, the vacuum pump is

working properly.

If the suction lift is too high,

reduce suction lift to a

maximum lift of 28 to 30 feet.

If the suction line is plugged, the

suction hose inner liner is

collapsed, the strainer is plugged

or the suction is buried or stuck

to the floor. Backflush to clean

the strainer.

If the strainer is clear, check the

inside of the hose for

obstructions. A collapsed hose

will return to normal without

vacuum. Replace the hose.

If the material pumped is too

thick or viscous, use a larger

diameter suction hose. If the

specific gravity is too high, move

the pump closer to the liquid.

Check to see that the drain,

surge control and backflush

valves are closed.

Check the suction hose for loose

fittings and check that the

strainer is under the liquid.

Shut off the pump, disconnect

discharge hose and inspect the

discharge check valve for wear

or not closing completely. If the

discharge check valve is

leaking, a good piece of PVC

discharge hose will collapse

and the pump should prime.

If there is a continued failure to

prime and build vacuum,

disconnect the suction hose and

do the dry vacuum test. If the

vacuum reading is normal and

there are no leaks, the problem

is a suction hose leak. If vacuum

reading is low, block off the

pump discharge and redo dry

vacuum test. If the vacuum is

still low, look for a large air

leak. If the seal oil level is low,

add oil and redo dry vacuum

test. No oil could indicate seal

failure. Listen at seal oil fill cap

for an air leak.

Primes but the flow is low.

Reduced flow at higher heads

could indicate that the impeller-

wearplate clearance needs

adjusting or that there is an

obstruction in the impeller.