Pump components – Multiquip MP200SDLSM Operation Manual User Manual

Page 19

DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 19

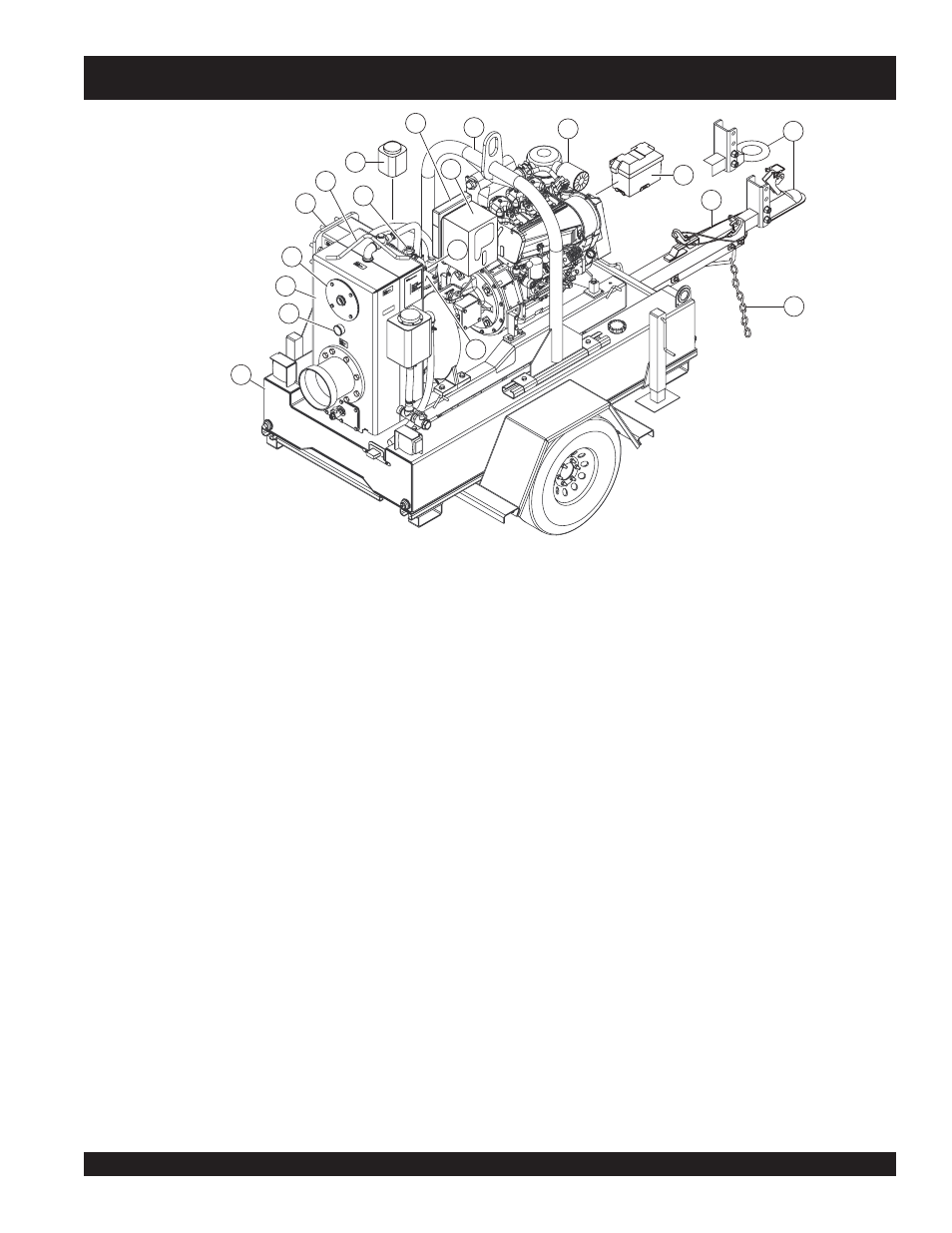

PUMP COMPONENTS

Figure 3-B. Pump

Components

Figure 3-B shows the location of the more components of

the Dry Prime pump, The function of each component or

control is described below:

16. Safety Chain – ALWAYS attach safety chain to the

towing vehicle. NEVER tow the pump with the safety

chain unattached! See towing section of this manual.

17. Towing Coupler/Ring – Attach this coupler to the towing

vehicle. Use only the specified ball diameter as indicated

on your coupler (2-5/16). Use of any other ball diameter

will create an extremely dangerous condition which can

result in separation of the coupler and ball or ball failure. A

3-inch tow ring is also available as an option.

18. Ajustable Tow Tongue – Tow tongue is adjustable by

removing locking pin to adjust tongue length then

reinserting pin to lock tongue in place.

19. Battery – Unit uses a +12VDC wet battery Group 31.

20. Engine – These pumps are equipped with either a

Deutz F3L914 or F4L914 three or four cylinder air-

cooled diesel engine.

21. Skid Lifting Bail –When lifting of the pump skid is required,

attach a strap or chain of adequate lifting capacity to lift the

skid.

22. Engine Control Box – Vandal proof (lockable) engine

control box displaying engine guages, tachometer,

tempertature, battery voltage, hour meter, oil pressure

and ignition switch.

23. Document Box – Contains all documentation relating

to the pump or engine.

24. Vacuum Pump Mechanical Seal Oil Reservoir – Oil

level should always be maintained to the FULL level

marked on the bottle.

25. Backflush Valve – Open valve to backflush wellpoints

or to clean suction strainer.

26. Priming Tank Lifting Bail – When removing of the

priming tank is required, attach a strap or chain of adequate

lifting capacity to lift vacuum pump.

27. Pump Discharge – Attach discharge hose to this port.

ALWAYS make sure discharge hose is securely

attached.

28. Float Valve – Regulates and controls vacuum level

during pump operation. Consist of self-aligning

reinforced rubber hinge that doubles as a seal and a

one piece welded float assembly.

29. Priming Tank – Vacuum system that creates a vacuum

in the outer priming tank, drawing water in. Water drawn

into the outer priming tank then flows into the volute,

priming the pump.

30. Vacuum Gauge – Vacuum gauge for priming system.

Monitors air discharge. Required when troubleshooting.

31. Fuel Tank – Holds 140 gallons (530 liters) of diesel

fuel

32. Volute Inspection Cover – Remove this cover to

inspect or clear the impeller.

33. Vacuum Pump – This unit uses a direct-drive 60 CFM

vacuum pump to remove large volumes of air to obtain

priming for the pump.

16

17

18

19

20

21

24

23

22

25

26

27

28

29

30

31

32

33