Mvh-120gh — maintenance – Multiquip MVH120GH User Manual

Page 19

MVH-120GH — OPERATION AND PARTS MANUAL — REV. #03 (10/24/07) — PAGE 19

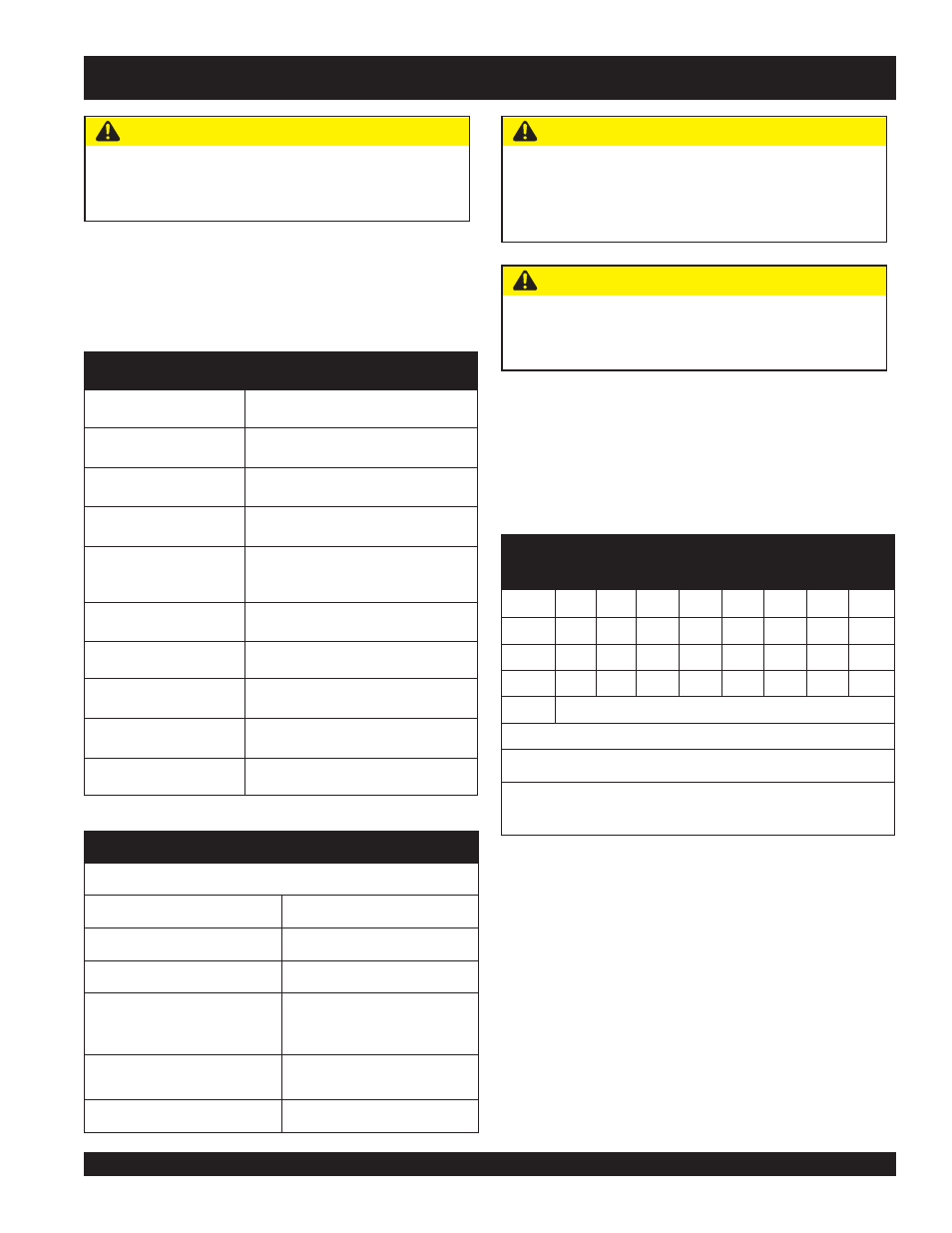

Inspection and Maintenance Service Tables.

1. To make sure your plate compactor is always in good

working condition before using, carry out the maintenance

inspection in accordance with Tables 4 through 6.

Daily Service

z Check for leakage of fuel or oil.

z Check for loose screws including tightness. See Table 6

below (tightening torque), for retightening:

z Remove soil and clean the bottom of compaction plate.

z Check hydraulic pump, piping and hose for any leakage.

A loosened hydraulic hose can be a cause for leakage.

Check hydraulic hose connections with wrench applied

for tightness.

z

C

heck engine oil.

MVH-120GH — MAINTENANCE

K

C

E

H

C

E

N

I

G

N

E

.

5

E

L

B

A

T

)l

a

u

n

a

M

e

n

i

g

n

E

e

t

a

r

a

p

e

s

e

e

s

,

s

li

a

t

e

d

r

o

F

(

m

e

t

I

n

o

i

t

a

r

e

p

O

f

o

s

r

u

o

H

l

e

u

f

r

o

li

o

f

o

e

g

a

k

a

e

L

)

y

a

d

y

r

e

v

e

(

s

r

u

o

h

8

y

r

e

v

E

s

d

a

e

r

h

t

g

n

i

n

e

t

s

a

f

f

o

s

s

e

n

t

h

g

i

T

)

y

a

d

y

r

e

v

e

(

s

r

u

o

h

8

y

r

e

v

E

d

n

a

k

c

e

h

c

li

o

e

n

i

g

n

E

t

n

e

m

h

s

i

n

e

l

p

e

r

y

r

e

v

e

(

s

r

u

o

h

8

y

r

e

v

E

.

x

a

m

d

e

if

i

c

e

p

s

o

t

h

s

i

n

e

l

p

e

R

(

)

y

a

d

)l

e

v

e

l

t

n

e

m

h

s

i

n

e

l

p

e

r

li

o

e

n

i

g

n

E

0

0

1

y

r

e

v

e

n

e

h

t

,

s

r

u

o

h

0

2

t

s

ri

f

t

A

s

r

u

o

h

g

n

i

n

a

e

l

c

r

e

n

a

e

l

c

ri

A

s

r

u

o

h

0

5

y

r

e

v

E

N

O

I

T

C

E

P

S

N

I

E

N

I

H

C

A

M

.

4

E

L

B

A

T

m

e

tI

n

o

it

a

r

e

p

O

f

o

s

r

u

o

H

k

c

e

h

c

g

n

it

r

a

t

S

)

y

a

d

y

r

e

v

e

(

s

r

u

o

h

8

y

r

e

v

E

s

w

e

r

c

s

t

s

o

l

r

o

d

e

n

e

s

o

o

L

)

y

a

d

y

r

e

v

e

(

s

r

u

o

h

8

y

r

e

v

E

s

t

r

a

p

d

e

g

a

m

a

D

)

y

a

d

y

r

e

v

e

(

s

r

u

o

h

8

y

r

e

v

E

g

n

il

l

o

rt

n

o

c

f

o

n

o

it

c

n

u

F

t

r

a

p

m

e

t

s

y

s

)

y

a

d

y

r

e

v

e

(

s

r

u

o

h

8

y

r

e

v

E

k

a

e

l

m

e

t

s

y

s

c

il

u

a

r

d

y

H

s

r

u

o

h

0

0

1

y

r

e

v

E

k

c

e

h

c

li

o

r

o

t

a

r

b

i

V

s

r

u

o

h

0

0

3

y

r

e

v

E

t

n

e

m

e

c

a

l

p

e

r

li

o

r

o

t

a

r

b

i

V

s

r

u

o

h

0

0

1

y

r

e

v

E

k

c

e

h

c

li

o

c

il

u

a

r

d

y

H

.

s

r

h

0

0

0

1

y

r

e

v

e

n

e

h

t

s

r

u

o

h

0

0

2

y

r

e

v

E

k

c

e

h

c

)

h

c

t

u

l

c

(

tl

e

b

-

V

r

u

o

h

0

0

2

y

r

e

v

E

.

6

E

L

B

A

T

r

e

t

e

m

a

i

D

)

m

c

/

g

k

.

n

i

(

E

U

Q

R

O

T

G

N

I

N

E

T

H

G

I

T

l

a

i

r

e

t

a

M

m

m

6

m

m

8

m

m

0

1

m

m

2

1

m

m

4

1

m

m

6

1

m

m

8

1

m

m

0

2

T

4

0

7

0

5

1

0

0

3

0

0

5

0

5

7

0

0

1

,

1

0

0

4

,

1

0

0

0

,

2

T

8

-

6

0

0

1

0

5

2

0

0

5

0

0

8

0

0

3

,

1

0

0

0

,

2

0

0

7

,

2

0

0

8

,

3

T

1

1

0

5

1

0

0

4

0

0

8

0

0

2

,

1

0

0

0

,

2

0

0

9

,

2

0

0

2

,

4

0

0

6

,

5

*

)

m

m

0

1

(

0

0

7

~

0

5

6

)

m

m

8

(

0

5

3

~

0

0

3

)

m

m

6

(

0

0

1

)

m

u

n

i

m

u

l

a

f

o

s

i

t

r

a

p

-

r

e

t

n

u

o

c

e

s

a

c

n

I

(

*

)

d

e

d

n

a

h

t

h

g

i

r

ll

a

e

r

a

e

n

i

h

c

a

m

s

i

h

t

h

ti

w

e

s

u

n

i

s

d

a

e

r

h

T

(

,t

l

o

b

h

c

a

e

n

o

d

e

k

r

a

m

s

i

l

a

i

r

e

t

a

m

f

o

y

ti

l

a

u

q

d

n

a

l

a

i

r

e

t

a

M

.

w

e

r

c

s

d

n

a

Inspection and other services should

always

be carried

out on solid and level ground with the engine shut down.

CAUTION

These inspection intervals are for operation under normal

conditions. Adjust your inspection intervals based on the

number of hours plate compactor is in use, and particular

working conditions.

CAUTION

Fuel piping and connections should be replaced every 2

years.

CAUTION