Mrh800gs — inspection, Danger – Multiquip MRH800GS User Manual

Page 22

PAGE 22 — MQ-MIKASA MRH800GS ROLLER — OPERATION AND PARTS MANUAL — REV. #5 (05/27/08)

MRH800GS — INSPECTION

Checking The Hydraulic System

1.

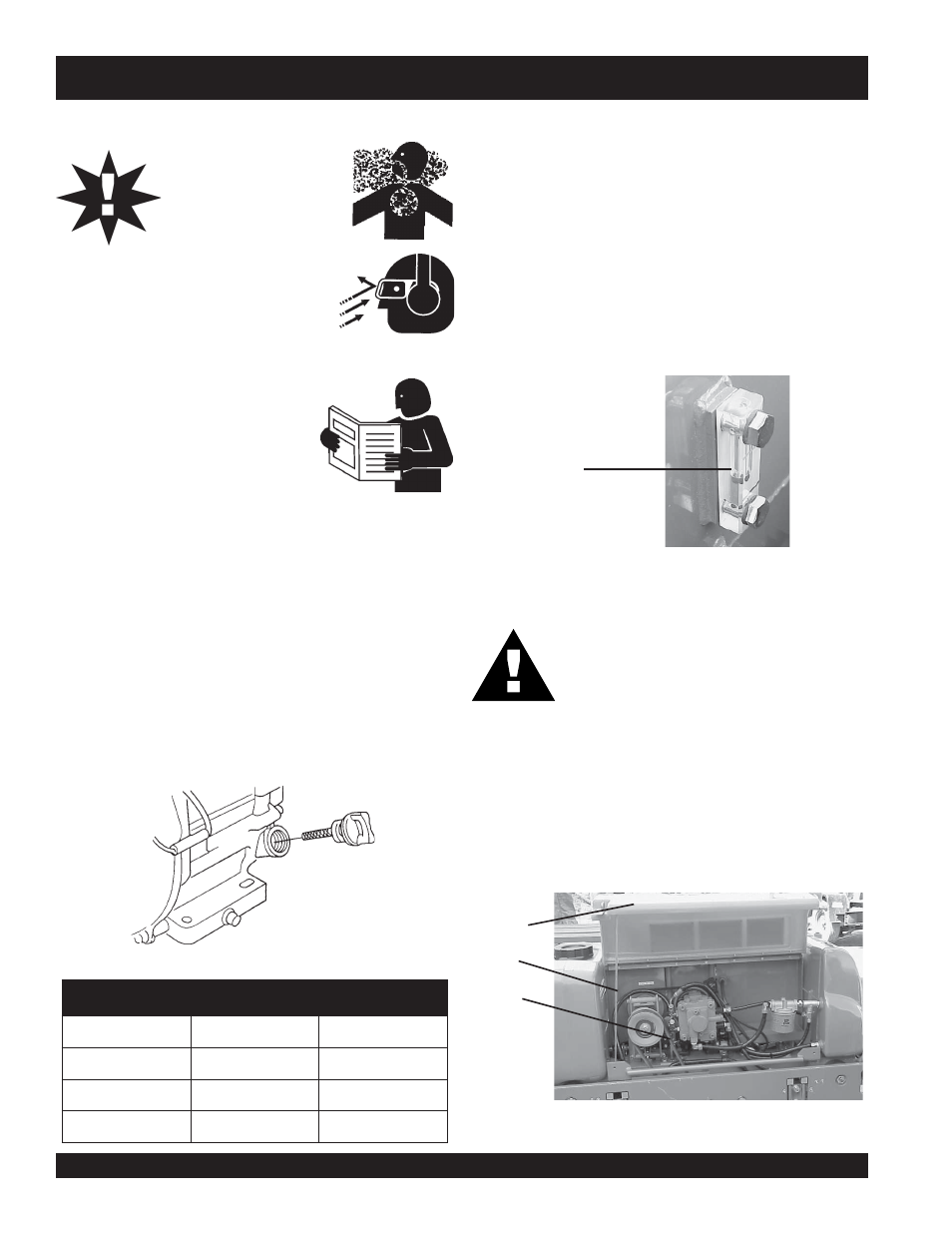

Check the oil tank level gauge (Figure 7). Oil level

should be at the middle indication of the gauge or

higher. Fill as required

2.

Check the surroundings of the oil tank, hydraulic

pump and motor for oil leakage.

Figure 6. Engine Oil Level

Figure 7. Hydraulic System Oil Level Gauge

Figure 8. Checking V-Belt Tension

Checking The V-Belt

1.

Remove the 2 bolts, one on each side of the center

cover, with a #13 socket wrench. Open the center

cover of the machine and support it with the strut by

inserting its end to the hole in the base (Figure 8).

2.

Check V-belt for proper tension. Insufficient tension

causes weak vibration.

Always keep hands and fingers away from pinch

points. Do not allow anyone to reach in on

dangerous sections of the machine to avoid any

accidents.

DANGER

Level should

be middle of

gauge or

higher

V-Belt

Center

Cover

Strut

Before Starting

1.

Read safety instructions at the

beginning of manual.

2.

Remove dirt and dust, particularly

in theengine cooling air inlet,

carburetor and air cleaner.

3.

Check the air filter for dirt and dust.

If air filter is dirty, replace air filter

with a new one as required.

4.

Check carburetor for external dirt and dust. Clean with dry

compressed air.

5.

Check fastening nuts and bolts for tightness.

6.

Understand the geographical features and regulations of

the job site.

Engine Oil Check

1.

To check the engine oil level, place the compactor on secure

level ground with the engine stopped.

2.

Remove the filler dipstick from the engine oil filler hole

(Figure 6) and wipe clean.

ALWAYS wear approved eye and hearing

protection before operating the compactor.

E

T

I

E

C

A

E

D

O

P

I

T

.

4

A

L

B

A

T

n

ó

i

c

a

t

s

E

a

r

u

t

a

r

e

p

m

e

T

e

t

i

e

c

a

e

d

o

p

i

T

o

n

a

r

e

V

a

tl

a

s

á

m

ó

C

°

5

2

0

3

-

W

0

1

E

A

S

o

ñ

o

t

O

/

a

r

e

v

a

m

i

r

P

C

°

0

1

~

C

°

5

2

0

2

/

0

3

-

W

0

1

E

A

S

o

n

r

e

i

v

n

I

a

j

a

b

s

á

m

ó

C

°

0

0

1

-

W

0

1

E

A

S

NEVER operate the

compactorin a confined

area or enclosed area

structure that does not

provide ample

free flow

of air

.

DANGER

3. Insert and remove the dipstick without screwing it into the

filler neck. Check the oil level shown on the dipstick.

4. If the oil level is low, fill to the edge of the oil filler hole with the

recommended oil type (Table 3). Maximum oil capacity is

1.16 quarts (1.1 liters).