0 load termination parameters, 0 modulus check at start temperature, 0 data storage parameters – MTS Fatigue Template User Manual

Page 57

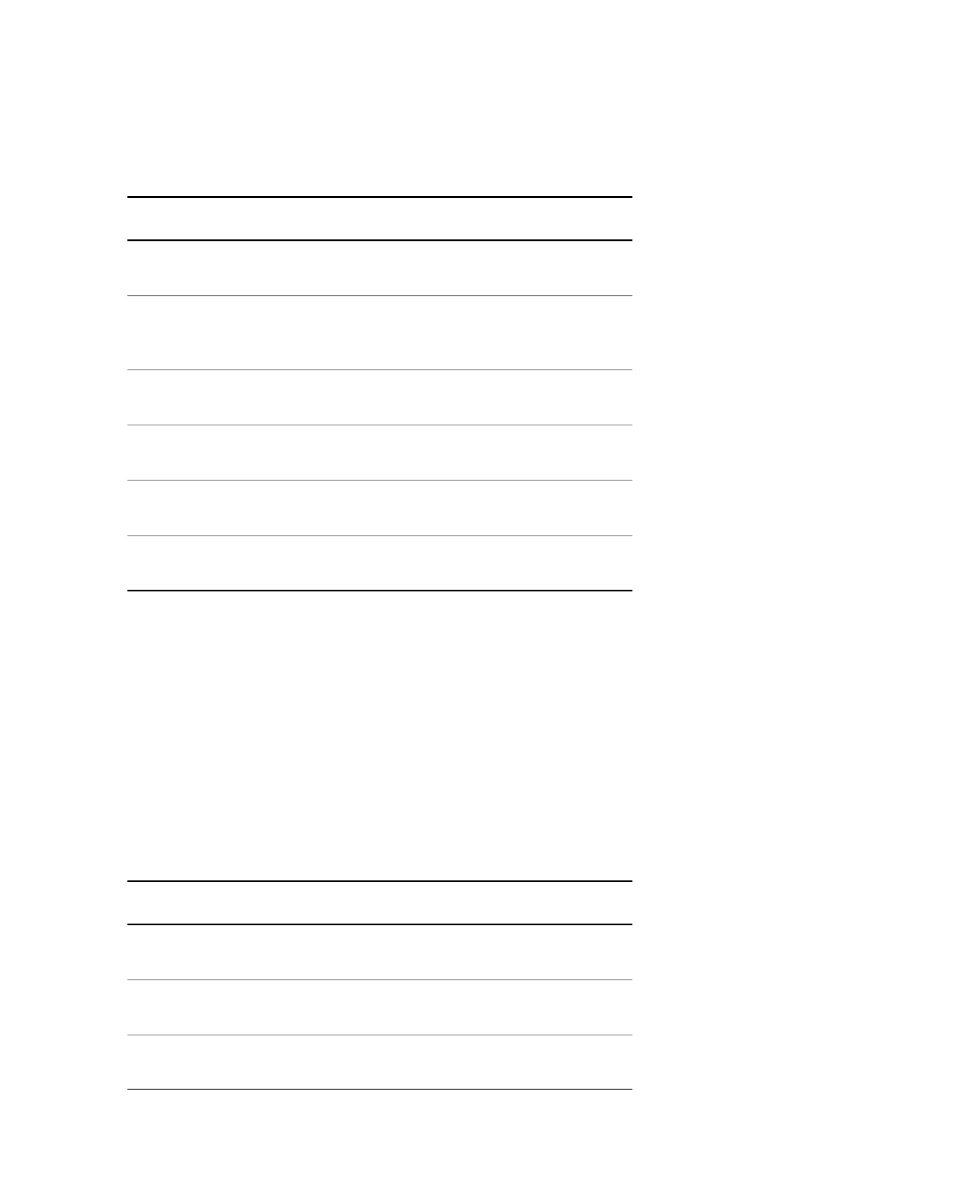

7.2.2.0 Load Termination Parameters

Load Termination Parameters

Description

Item

Specify a number of cycles for the maximum length

of the test.

Total Cycles

Specify a number of cycles after which the specimen

is expected to be stable and beyond hardening or

softening.

Cycles for Stable

Cycle

Specify a percentage used to calculate stability.

Stable Cycle

Percent

Specify a percentage that is used to calculate the

stable strain range and crack initiation.

Crack Initiation

Change

Specify a percentage that is used to calculate the

stable load range and specimen failure.

Load Failure

Change Percent

Specify a percentage that is used to calculate if the

load control peak occurs outside the control range.

Peak Load Level

Control Change

7.2.3.0 Modulus Check at Start Temperature

You should perform a modulus check before you run a test. The standard template allows you to check the

modulus at start temperature and test temperature (for elevated temperature tests). The start temperature

modulus check helps determine if the system is set up correctly. For example, if you have not pulled the zero

pin from your extensometer, the modulus is incorrect. If you type incorrect specimen dimensions, the modulus

is incorrect.

7.2.4.0 Data Storage Parameters

Data Storage Parameters Properties

Description

Item

Sets the number of cycles to save to disk at the end

of the test or when the test stops.

Ending Cycles

Sets the amount of change that must occur in the

maximum load between saves to disk.

Load Storage

Change

Sets the value of N, which is the rate (number) of

peak-valley cycles for a store to disk to occur. For

PV Nth Cycle

Stored

MTS TestSuite 57

7.0 ASTM High-Cycle Fatigue (HCF) Load Test Template