MTS Series 249G2 Swivels User Manual

Page 31

Considerations For Superbolt Torquenuts

Series 249G2 Swivels

Maintenance

31

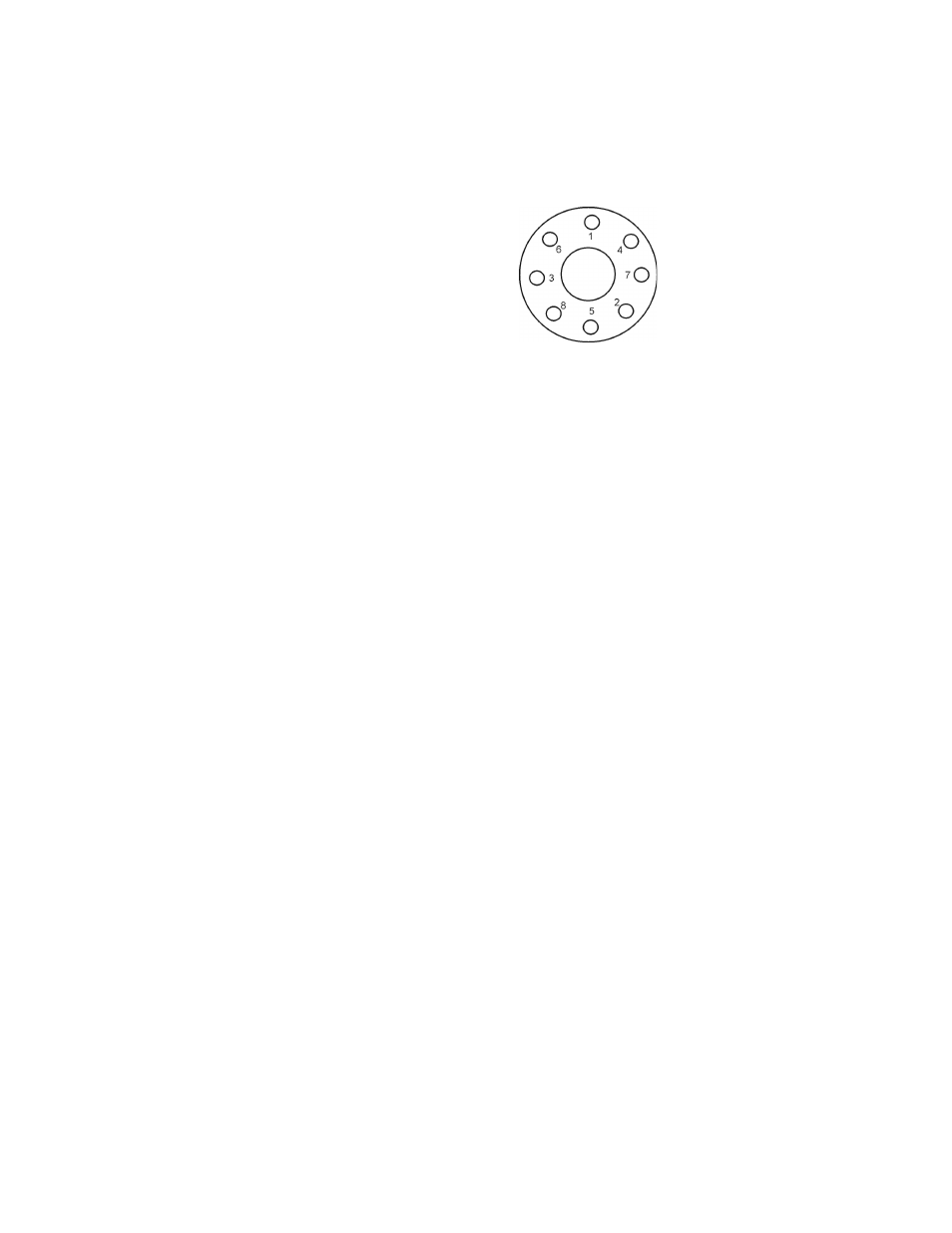

1. Following the sequence shown below, loosen every third jackbolt one-

eighth turn at a time. Repeat this process until all of the jackbolts can be

turned by hand. This will prevent a single jackbolt from bearing the entire

load of the Torquenut

.

2. After all the jackbolts have been loosened, loosen the Torquenut on the main

thread by turning the nut by hand or with a bar inserted between the

jackbolts (do not damage the threads of the jackbolts).

3. Ensure that none of the jackbolts protrude through the base of the

Torquenut, and that the surface of the Torquenut rests smoothly on the

hardened washer. Tighten the Torquenut on the main thread by turning the

nut by hand or with a bar inserted between the jackbolts (do not damage the

threads of the jackbolts).

4. After the backlash adjustment has been made, hand-tighten each jackbolt to

ensure even seating of the main thread.

5. Using the torque wrench, tighten the jackbolts in the same sequence they

were loosened. Torque in 34 N·m (25 ft-lbf) increments until all screws

reach 61 N·m (45 ft-lbf).

It will be necessary to torque each jackbolt several times, because the

preceding jackbolts will loosen as the subsequent jackbolts are torqued.

Using the same method, torque each jackbolt to a final clamping torque of

61 N·m (45 lbf·ft).