Storage preparation, Maintenance, Cd a – MotorGuide Saltwater User Manual

Page 35

MAINTENANCE

eng

31

EVERY 100 HOURS OF USE OR ANNUALLY

• Periodically lubricate all the pivot points with a nonaerosol,

nonsolvent based lubricant.

IMPORTANT: Never use an aerosol lubricant to grease or oil any part

of the unit. Many aerosol lubricants contain harmful propellants that

can cause damage to various parts of the trolling motor.

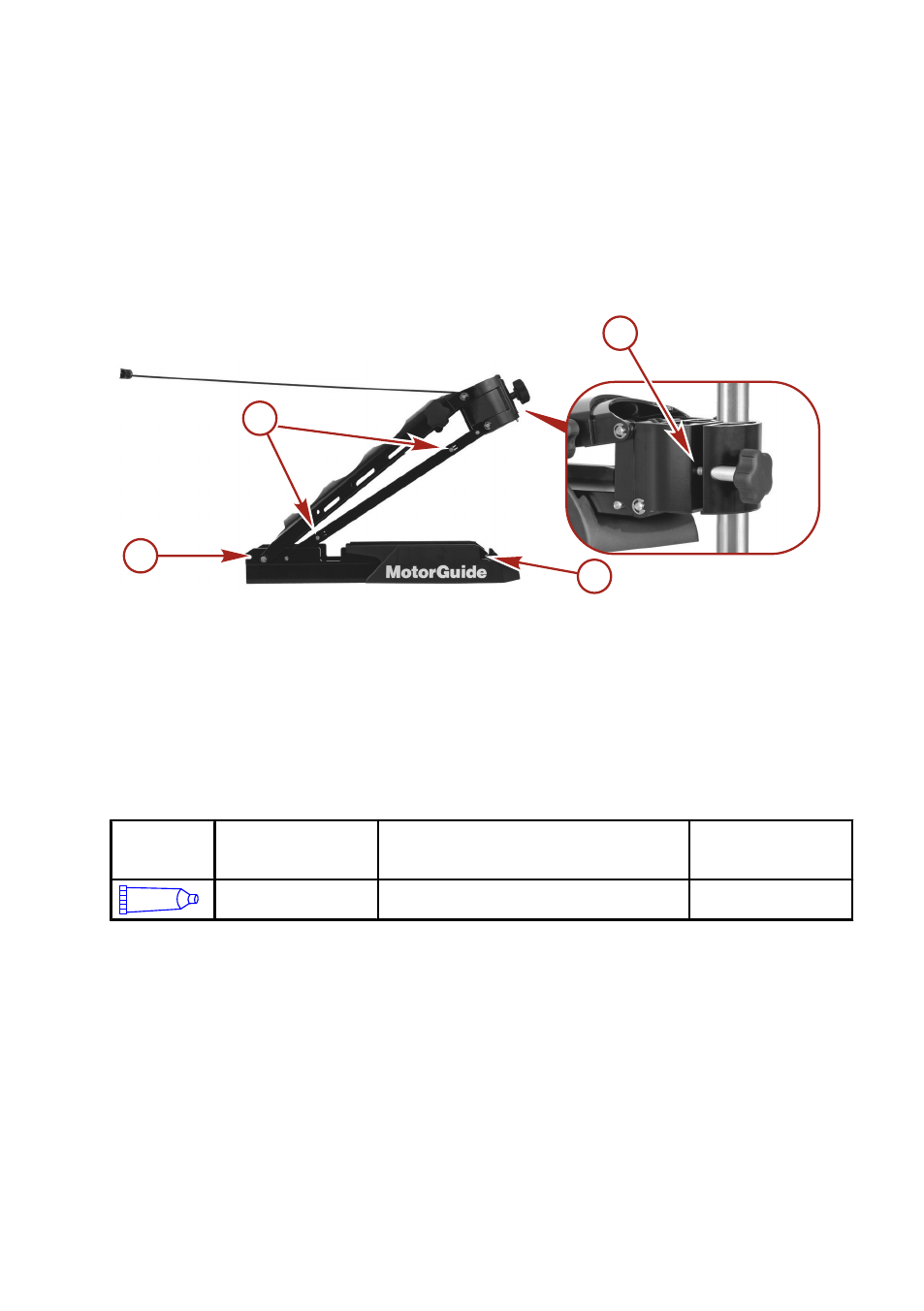

Lubrication points

a -

Rear deck channel grooves

b -

Lockslide pin

c -

Door knob shaft

d -

Forward deck channel grooves

Tube Ref

No.

Description

Where Used

Part No.

95

2-4-C with Teflon

Pivot points

92-802859A 1

• Check the tightness of bolts, nuts, and other fasteners.

• Inspect the battery. Refer to Battery Inspection.

Storage Preparation

The major consideration in preparing your trolling motor for storage is

to protect it from corrosion and damage caused by freezing of trapped

water.

c

d

a

41572

b