Bryant DURAPAC PLUS 581B User Manual

Page 5

—

5

—

Size gas supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas

connection.

Support gas piping as shown in the table in Fig. 9. For exam-

ple, a

3

/

4

-in. gas pipe must have one field-fabricated support

beam every 8 ft. Therefore, an 18-ft long gas pipe would have

a minimum of 3 support beams. See Fig. 9 for typical pipe

guide and locations of external manual gas shutoff valve.

NOTE: If accessory thru-the-bottom connections and roof

curb are used, refer to the Thru-the-Bottom Accessory

Installation Instructions for information on power wiring

and gas connection piping. Power wiring, control wiring and

gas connection piping can be routed through field-drilled

holes in the basepan, which is specifically designed and dim-

pled for drilling the accessory connection holes.

CAUTION: When connecting the gas line to the

unit gas valve, the installer MUST use a backup

wrench to prevent damage to the valve.

NOTES:

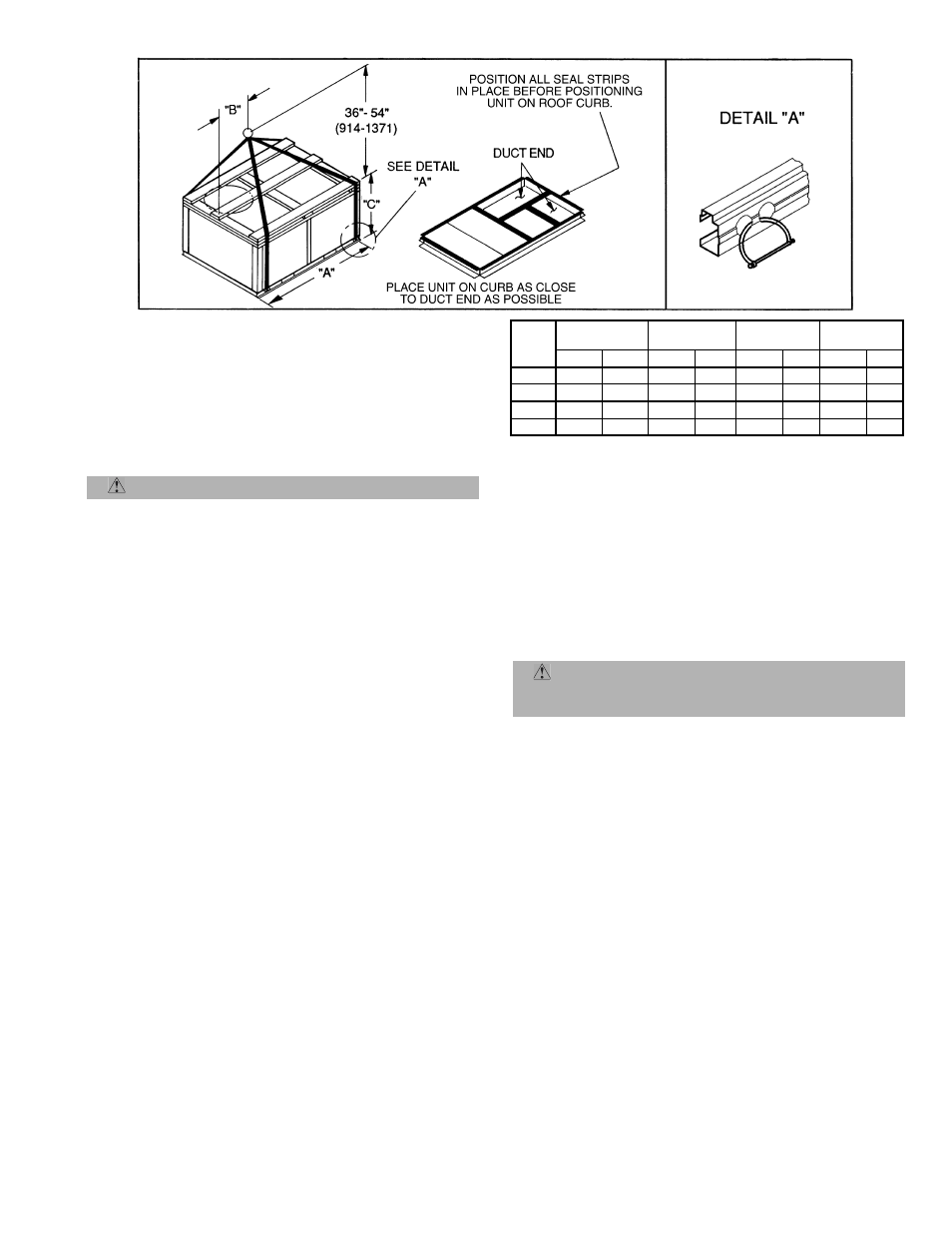

1. Place unit on curb as close as possible to the duct end.

2. Dimension in ( ) is in millimeters.

3. Hook rigging shackles through holes in base rail as shown in detail

“A.” Holes in base rails are centered around the unit center of grav-

ity. Use wooden top skid when rigging to prevent rigging straps

from damaging unit.

4. Weights include base unit without economizer. See Table 1 for unit

operating weights and economizer weights.

5. Weights include base unit without the Perfect Humidity™ dehumid-

ification system. See Table 1 for additional unit operating weights

with the Perfect Humidity system.

CAUTION:

All panels must be in place when rigging.

Fig. 6 — Rigging Details

UNIT

581B

OPERATING

WEIGHT

“A”

“B”

“C”

lb

kg

in.

mm

in.

mm

in.

mm

036

530

240

73.69

1872

35.50

902

33.31

847

048

540

245

73.69

1872

35.50

902

33.31

847

060

560

254

73.69

1872

35.50

902

33.31

847

072

635

288

73.69

1872

35.50

902

33.31

847