Marshalltown FCS86 SURFACE SHARK Floor Stripper User Manual

Page 29

FCS86 SuRFACE ShARK™ FLooR STRIPPER

PAgE 29

LUBRICATION REQUIREMENTS

Parts Required:

1 each, standard grease gun filled with one of the

following: ESSo beacon 325, Shell Alvania

#2, Chevron SRI, or equivalent.

1 each, container of dry film lubricant.

1) Lubricate the caster wheel bearings with a dry film

lubricant only. Dry film lubricants dry immediately upon

contact. use sparingly. Excess lubricant will attract

the fine grained, powdered materials described and

directly affect bearing service life.

Do not lubricate the caster wheels with any

lubricant other than a dry film type. Grease

and many other liquid type lubricants will

attract foreign material accumulations that

can reduce bearing service life.

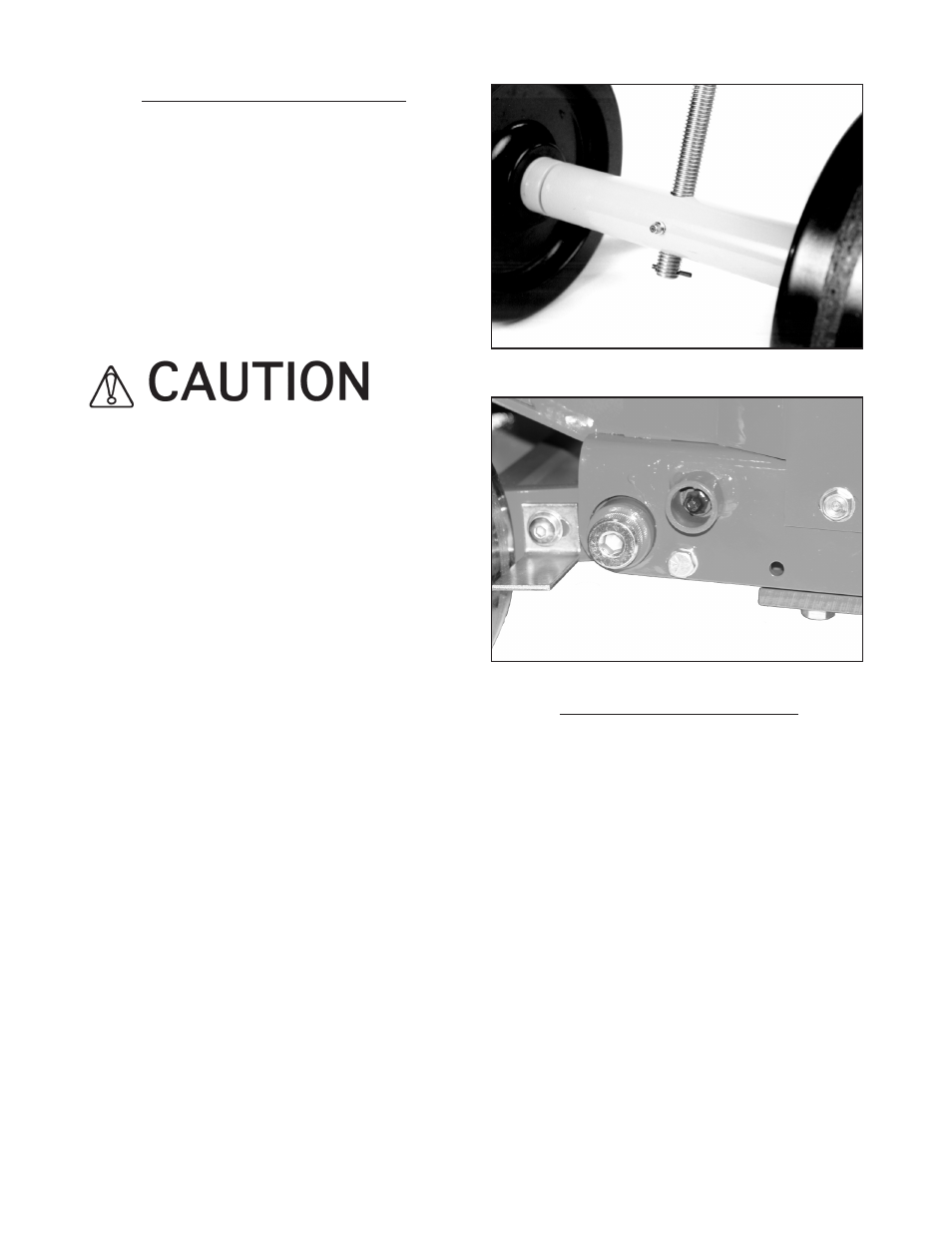

2) Zerk® type grease fittings are provided at two

locations:

a) To lubricate the back Saver™ blade Control System

jackscrew. Keep the jackscrew properly lubricated with

grease to minimize friction when operating the blade

control lever. Excessive lubrication will attract foreign

material accumulations that can reduce jackscrew

service life. FIguRE 29.

b) To lubricate the exciter bearing and bearing housing

casting. The exciter utilizes a shielded type ball bearing.

The Zerk® fitting provides lubrication for both the balls

and self-aligning feature of the bearing unit. FIguRE

30. grease interval will vary depending upon machine

utilization rates and operating environment factors.

grease accumulation on the bearing and housing

would indicate excessive lubrication.

Sleeve type bearings utilized for the operator handle

are self-lubricating and will not normally require

additional lubrication during their normal service life.

ball type bearings are shielded or sealed and will

not normally require additional lubrication during their

normal service life.

FIguRE 29

FIguRE 30

ELECTRIC MOTOR SERVICE

The electric motor is capable of operating for many

years with a reasonably small amount of maintenance.

before attempting to service the motor, disconnect

the Floor Stripper from the power supply. Clean the

motor surfaces periodically, preferably with a vacuum

cleaner. heavy accumulations of dirt and lint will result

in overheating and premature failure of the motor.

The electric motor is equipped with higher capacity

ball bearings and under normal service and ambient

temperatures, should not require relubrication for

many years. If you feel that the motor requires

relubrication, contact the local representative of the

motor manufacturer for specific information.

The seals utilized with the motor are intended to

deliver a longer service life in a dust filled atmosphere.

When replacing the seals, utilize only components

meeting the original factory specifications.