Marshalltown FCS86 SURFACE SHARK Floor Stripper User Manual

Page 24

PAgE 24

FCS86 SuRFACE ShARK™ FLooR STRIPPER

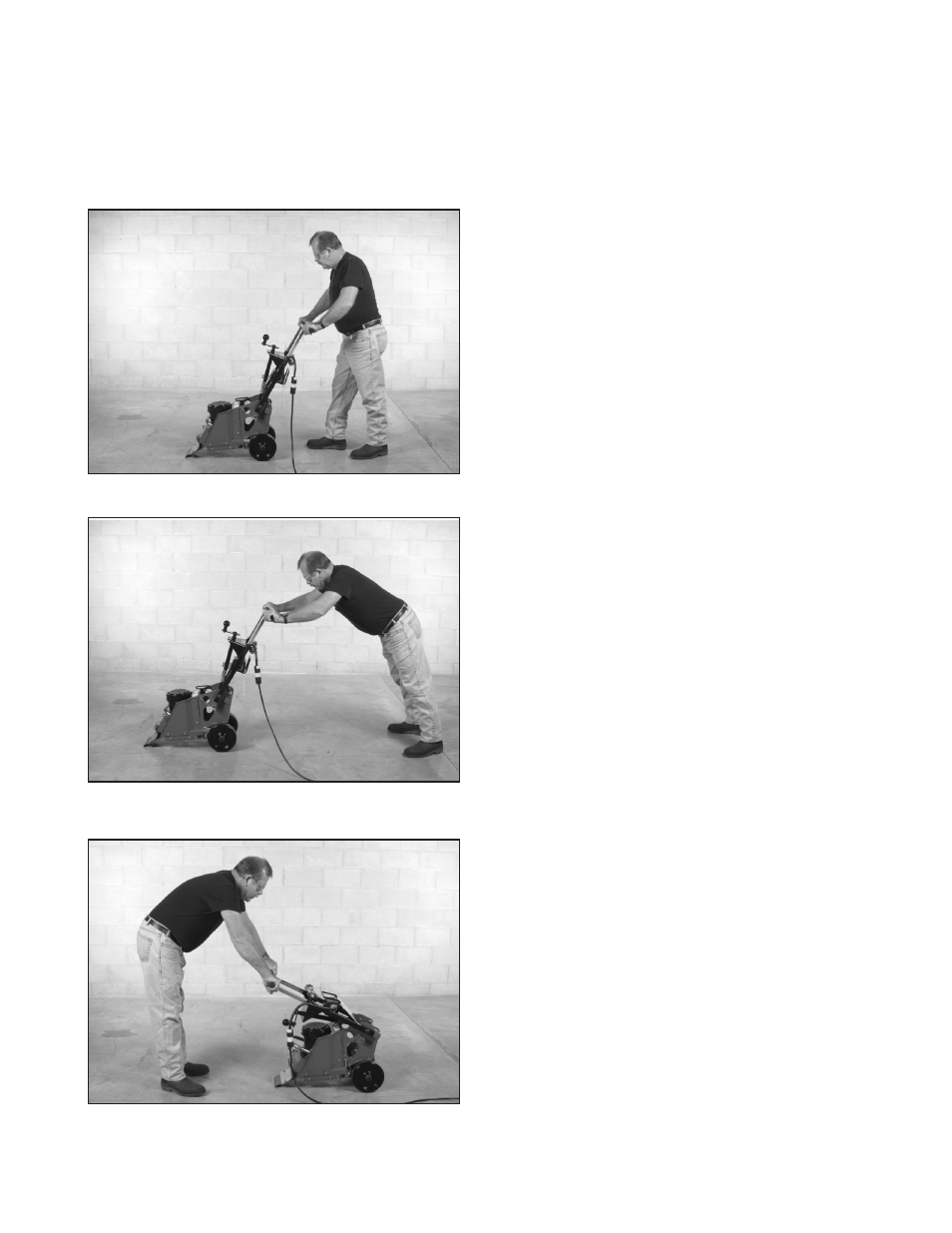

Keep feet a comfortable distance apart to help provide

stability and locomotion force. A proper operator

position is depicted in FIguRE 23. Improper operator

positions are depicted in FIguRES 24 and 25. The

proper and improper operator positions depicted in

this manual are not all inclusive.

FIguRE 23

FIguRE 24

FIguRE 25

4) The wide variety of potential covering materials

along with the corresponding variety of job site

environments, makes it impossible to develop a

standardized operating procedure for the Floor Stripper.

use of the Floor Stripper will require constant trial and

error testing until satisfactory results are achieved.

Experience, gained over time, along with good common

sense will help minimize the amount of necessary

testing. Many factors will directly affect the operating

parameters and/or techniques utilized for a specialized

job application. Some of these factors include:

a) Work surface material yield and tensile values. As

a general rule, these values will determine material

removal rate per unit of time. Materials with high

yield and tensile values will characteristically resist/

limit penetration. For such materials, the accepted

procedure is to decrease blade width and determine

optimum blade angle relative to the floor surface.

This will require increasing or decreasing the blade

angle with the back Saver

™

blade Control System.

other added benefits to this technique are decreased

vibration, less operator fatigue and increased

component service life.

b) higher material removal rates can sometimes be

achieved by making a series of passes 90 degrees

to each other to form a waffle like pattern. This

technique is especially useful when removing deeper

accumulations of rubber type materials, material

residues and dirt debris from industrial floors.

c) The covering removal process can be extremely

abrasive to the blade cutting edge. blades can be

sharpened in the field by the use of the metal file

stored on the fixed section of the operator handle. use

of the file in the field will not duplicate the original blade

manufacturing process, but can significantly increase

overall productivity rates versus the continued use of

a dull blade. Remove the blade from the Floor Stripper

per the procedures outlined in this manual. Clamp the

blade in a suitable vice. use the file to sharpen the

blade with a procedure similar to that of sharpening a

rotary lawnmower blade. FIguRE 26.