Marshalltown FCS86 SURFACE SHARK Floor Stripper User Manual

Page 14

PAgE 14

FCS86 SuRFACE ShARK™ FLooR STRIPPER

Improper knob tension and/or improperly

securing the operator handle to the main

frame can result in an unstable platform

configuration. An unstable platform

configuration can result in property damage

and/or personal injury.

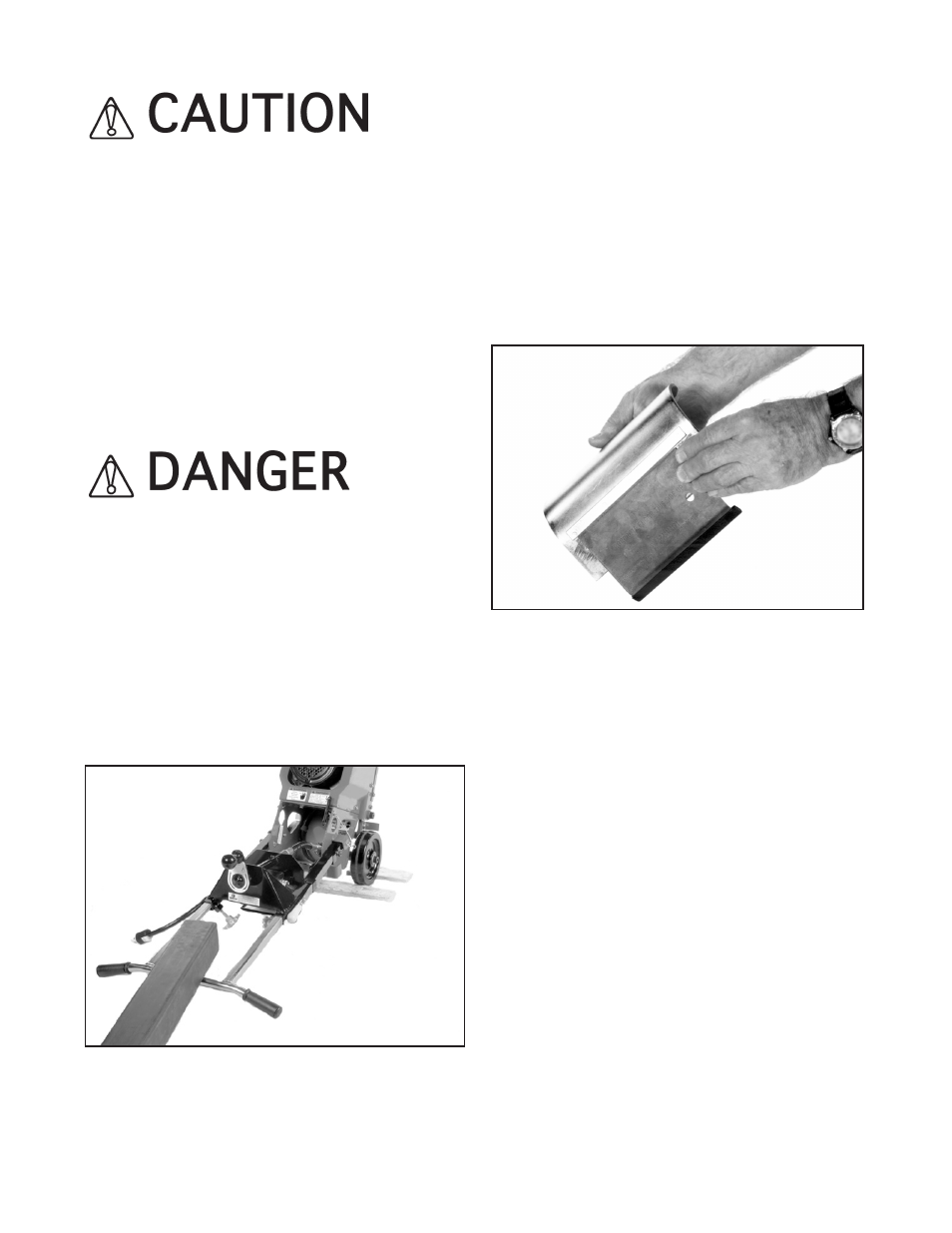

4) Tilt the Floor Stripper back until the operator

handle comes in contact with the surface. The Floor

Stripper may not be in a stable position in this

configuration. To minimize the possibility of property

damage and/or personal injury, properly secure an

appropriate weight to the handle for added stability.

other means can also be utilized to support the frame

and provide proper machine stability. Appropriate

wheel chocks are also recommended. FIguRE 10.

EXERCISE EXTREME CAUTION WHEN

WORKING NEAR OR UNDER THE FLOOR

STRIPPER WITH THE OPERATOR HANDLE

TILTED BACK IN THE SERVICE POSITION.

I F T H E F L O O R S T R I P P E R I S N O T

P O S I T I O N E D

I N

A

S T A B L E

C O N F I G U R A T I O N , W I T H A D E Q U A T E

COUNTERWEIGHT PROPERLY SECURED,

UNEXPECTED MOVEMENT CAN ALLOW

THE MACHINE TO FALL BACK TO THE

WORK SURFACE. THIS OCCURRENCE CAN

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

FIguRE 10

5) Wear proper safety apparel and equipment. use

the T-handled Allen wrench to loosen the button head

cap screws which secure the fence plate to the exciter

plate. This will allow the blade to slide in between

the fence plate and the exciter plate. IT IS NoT

NECESSARy To REMovE ThE FENCE PLATE

FRoM ThE EXCITER PLATE. The fence plate has

an integral stop which the edge of the blade thrusts

up against. FIguRE 11. blades are provided with a

covering that protects the cutting edge. Do not

remove the protective covering until you are ready

to operate the Floor Stripper. Exercise extreme

caution when removing and/or reinstalling the

protective cover.

FIguRE 11

6) Two attachment configurations for blades are

utilized. Narrow (less than 6 inches (152 mm) wide)

blades are positioned between the two button head

cap screws and thrust up against the fence plate

stop. FIguRE 12. use the T-handled Allen wrench to

tighten the button head screws. Wider (greater

than 6 inches (152 mm) wide) blades incorporate a

slotted design which slides around the button head

cap screws. The slots afford increased clamping

pressure for the wider blades during the covering

removal process. SLoTS ALSo MAKE IT

uNNECESSARy To REMovE ThE FENCE PLATE

FRoM ThE EXCITER PLATE. use the T-handled

Allen wrench to tighten the button head cap screws.

FIguRE 12. If the Floor Stripper is to be utilized

immediately, remove the protective cover from

the blade. If the Floor Stripper is not be utilized

immediately, do not remove the protective covering

from the blade.