Three point saddle bend, 3 point saddle bend table, 45° center bend – Klein Tools 56206 User Manual

Page 9: 60° center bend

9

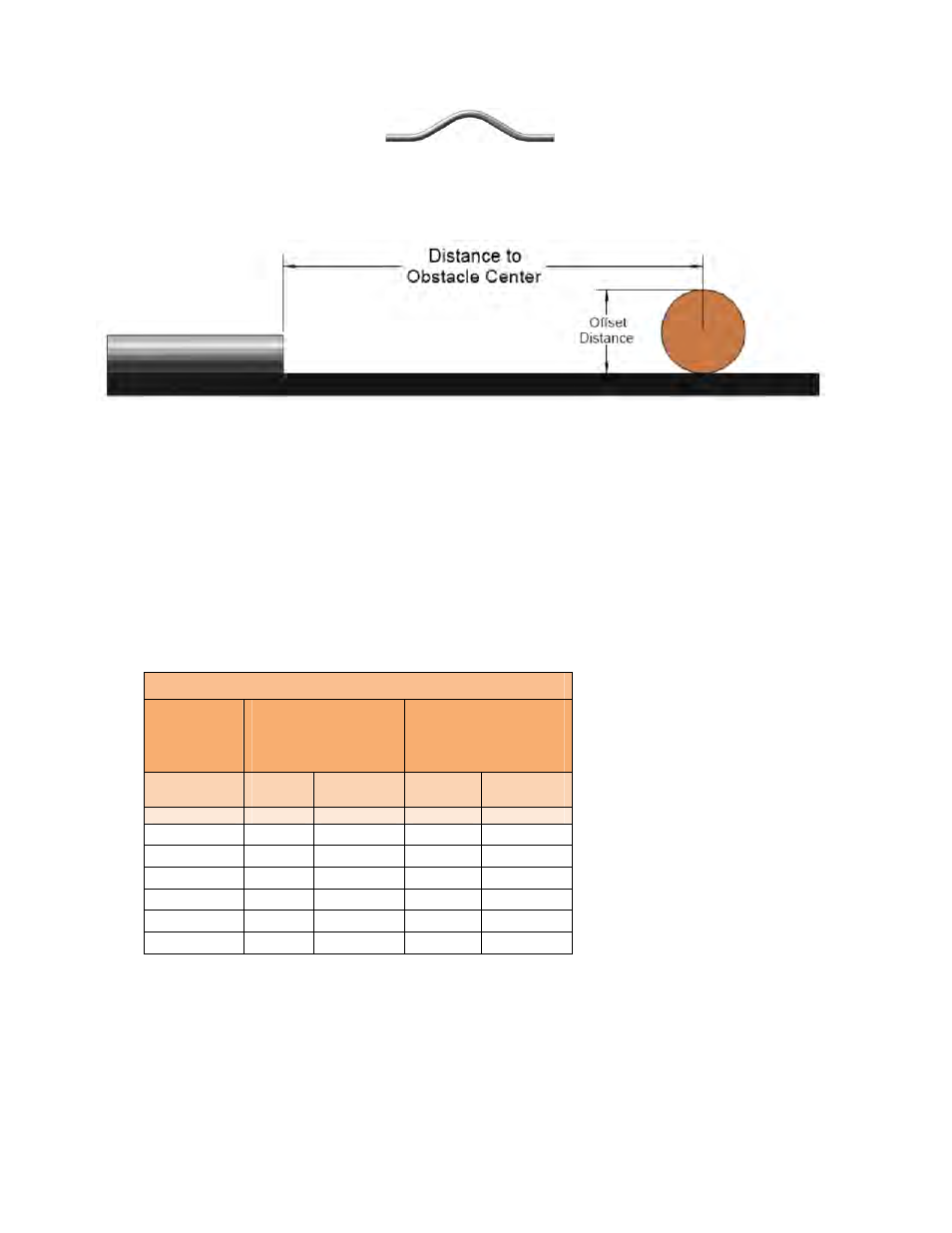

Three Point Saddle Bend:

The three point saddle bend is a variant of the offset bend since it is an offset bend that returns to the

original in-line run after clearing an obstacle. This bend is intended to bridge over obstacles such as

existing conduit or plumbing running perpendicular to the intended conduit installation.

1.

Determine/measure the offset distance necessary to clear the obstacle and how far away the

saddle bend will need to be from the edge of the conduit. Unlike the offset bend you must

measure to the center of the obstacle to bridge over.

2.

Choose the angle that will be used for the center bend. The other two return bends will be 1/2

the center angle chosen. If the center angle is 45°, the two return bends will be 22.5°. Use the

table to calculate the distance between bends and how much shrink is to occur to the conduit

due to the bends.

Example:

As an example, the offset

distance of an obstacle is 2” and the

distance to obstacle’s center point is 20”.

The installation allows for a 45° saddle

bend. Note: The choice of degree is usually

the installer’s choice and most of the time

the installation location will determine what

degree will fit.

3.

Calculate the value needed to place your first mark on the conduit. This number is determined

by the Measured Distance to Center Point of the obstacle plus the Shrink from the 3 Point

Saddle Bend Table that will occur.

(Measured Distance to Center Point) + (Shrink) = Center Mark

Example: 20” + 3/8” = 20-3/8”

3 Point Saddle Bend Table

Degree of

Bend:

45° Center

Bend

22.5° Return Bends

60° Center

Bend

30° Return Bends

Obstruction

Height

Shrink

Amount

Distance off

Center Mark

Shrink

Amount

Distance off

Center Mark

Every inch Add:

3/16”

2-1/2”

1/4”

2”

1”

3/16”

2-1/2”

1/4”

2”

2”

3/8”

5”

1/2”

4”

3”

9/16”

7-1/2”

3/4”

6”

4”

3/4”

10”

1”

8”

5”

15/16”

12-1/2”

1-1/4”

10”

6”

1-1/8”

15”

1-1/2”

12”