Klein Tools 8900-1/4 User Manual

Klein Tools Tools

8900-1/4, 8900-3/8, 8900-1/2

• Bends 1/4" to 1/2" (6 mm to 12 mm) O.D. tubing.

• Swivel handle can be repositioned midway through a bend when both handles begin to meet.

• Allows easy fabrication of bends up to 180° with reduced effort and better control without crossing

the handles.

• For bending soft copper, aluminum, brass, steel, stainless steel and other tubing. Avoid use with

extremely thin walled and hard tempered tubing. (Type M tubing is not recommended for bending.)

The lever swivel-handle type tube bender incorporates a start position of approximately 100° for

ease of bending, and a swivel handle mechanism that permits repositioning one handle when the

handles approach parallel. This feature simplifies fabricating bends up to 180° by reducing effort,

improving control and eliminating crossing of handles.

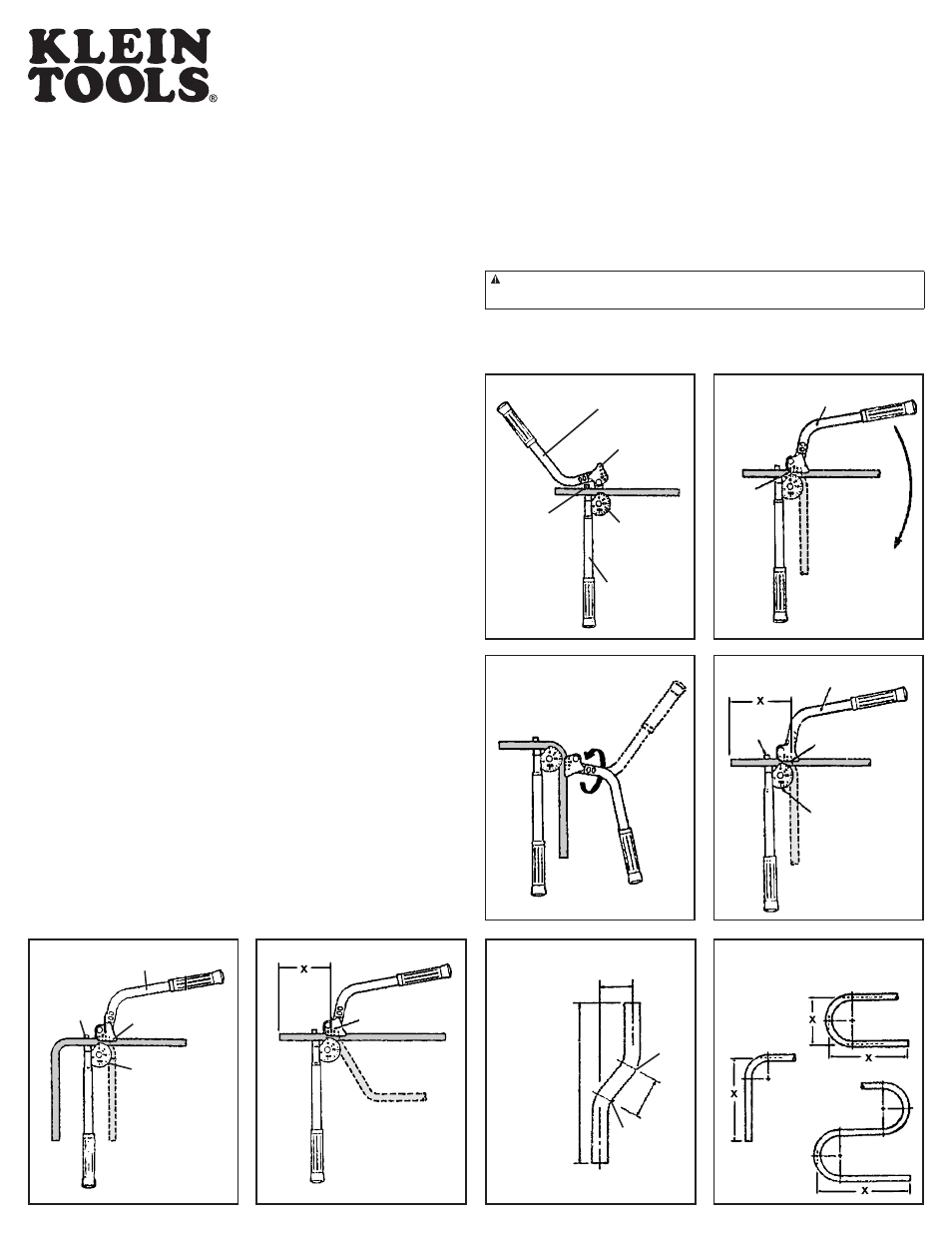

TO BEND TUBING

1. Raise the swivel handle and position tubing into the guide groove. It is important that the tube is

engaged with the tube clamp to prevent tube slippage. (See Fig. 1).

2. Lower the swivel handle until the “0’s” on the form wheel and form lever are aligned, then pull the

handle down until the desired bend angle is obtained. Degree of bend is indicated when the “0”

mark on the form lever aligns with the degree mark on the form wheel. (See Fig. 2).

3. For ease in completing bends greater than 90° (180° max.), reposition the swivel handle by rotat-

ing counterclockwise. (See Fig. 3). An over-center position automatically locks the swivel handle in

place when bending force is applied.

90° BENDS

1. Measure from end of tube to where you want the first bend, and place a mark on the tubing at that

exact point.

2. Position tube in bender. If the end from which you measured is left of the tube clamp, the

measured mark should be directly over graduation “L” located on the right side of the form lever.

(See Fig. 4).

3. If the end from which you measured is placed to the right of the tube clamp, the measured mark

should be directly over graduation “R” on the form lever. (See Fig. 5).

4. With a steady motion, pull the swivel handle around until the “0” mark on the swivel handle is

directly opposite the 90° mark on the form wheel. (See Fig. 5).

45° BENDS

1. Measure from end of tube to where you want the first bend, and place a mark on the tubing at that

exact point.

2. Position tube in bender. If the end from which you measured is left of the tube clamp, the

measured mark should be directly over graduation “L” located on the right side of the form lever.

(See Fig. 4).

3. If the end from which you measured is placed to the right of the tube clamp, the measured mark

should be directly over graduation “R” on the form lever. (See Fig. 5).

4. With a steady motion, pull the swivel handle around until the “0” mark on the swivel handle is

directly opposite the 45° mark on the form wheel. (See Fig. 6).

DOUBLE 45° OR 90° OFFSET BENDS

When forming a tube offset, it is necessary to make two bends. Mark the tube at both bend locations before

proceeding. Wherever possible, use 45° bends.

FIGURING OFFSET BENDS

1. Refer to the offset bend calculator chart (see last page). Note that the “Y” dimension in the chart

gives the total amount of offset required. The “X” dimension in the chart gives the length of tubing

you will use for a given application.

2. To figure out the length of tubing which is needed to meet your offset requirements, follow this

example: For a 45° angle with a 2-1/2” offset, refer to the chart under “Angle of offset 45°”. Next,

refer to the “Y” dimension and find 2-1/2” offset. The figure to the right under “X” dimension will

be the length of tubing you will use. In this example, the required length is 3-17/32”.

3. Now determine where you want the center of the offset bend on the tube. Make a reference mark

“A” at this point. (See “A” on Fig. 7). From this point, measure the “X” dimension (length of tubing

determined in step 2) and make a mark “B.” You are now ready to make the bends.

NOTE: The “Offset Bend Calculator” chart allows you a “Y” dimension of up to 6 inches. If your offset

requirements should exceed this number, you must choose an offset from the table that is a multiple of the

offset you need. For example, if you have an offset requirement of 20", find the multiple (5") on the chart

under dimension “Y”. Take the “X” dimension to the right of this and multiply by 4. This will be the length of

tubing you need for your offset. In this case it is 28-1/4".

Warranty

See retailer or visit www.kleintools.com for details.

WARNINGS:

Always wear approved eye protection.

•

Never use on or near live electrical circuits.

•

INSTRUCTIONS FOR LEVER SWIVEL-HANDLE TYPE TUBE BENDER

Swivel handle form lever

Tube clamp

Form wheel

handle

Form wheel

Guide

groove

Fig. 1

Swivel handle

form lever

Pull handle

this direction

Use this

mark for

degree

of bends

Fig. 2

Fig. 3

Fig. 4

Tube

clamp

Form wheel

Swivel handle

Use “L” mark

Use “R”

mark

Tube clamp

Swivel handle

Form wheel

Fig. 5

Fig. 8

For reference only

Fig. 6

Use “45” mark

Fig. 7

Mark B

Offset dimension “Y”

“X” dimension

Mark A