90° stub-up bend, Conduit size stub height – Klein Tools 56206 User Manual

Page 2

2

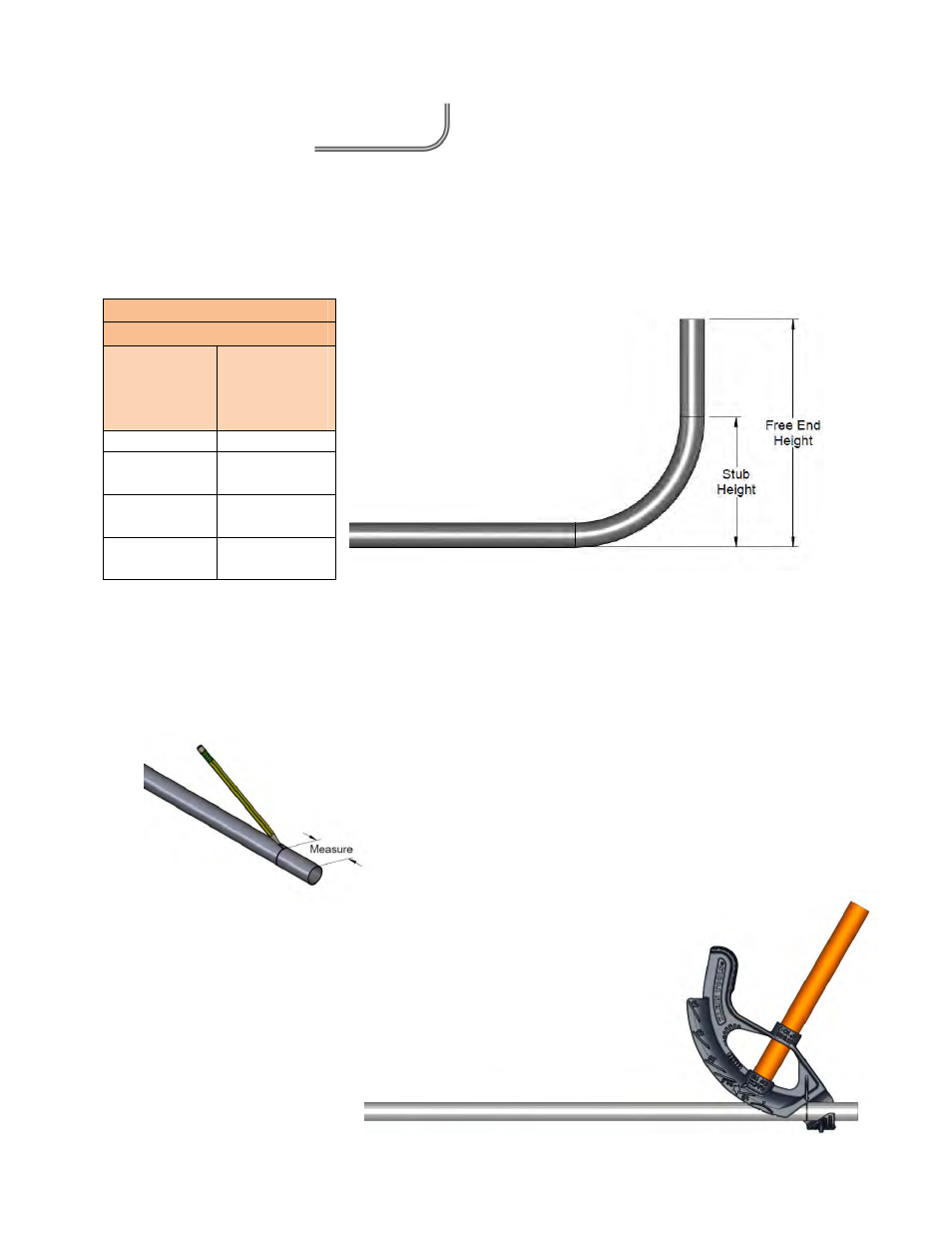

90° Stub-Up Bend:

The stub bend is made by bending a piece of conduit into an L shape or 90° bend by placing the free end

(short end) of the tube to a predetermined length as indicated in the diagram below. This is the most

common bend and is a building block for other bends. Common uses for this bend are: Running conduit

into electrical boxes, running conduit up or down walls, running conduit into walls through floors and

ceilings and making inner and outer corner turns.

1.

Determine the overall free end height of the conduit you want after the bend.

2.

From the overall free height, subtract the stub height listed in the Bender Take-Up Table for the

conduit size you are bending.

Klein Tools has provided the correct stub height on each bender head.

3.

On the conduit, measure from the free end to be bent up the calculated number and mark the

conduit.

As an example, to bend 3/4” EMT conduit have a free end height

of 8.5”, the table indicates to subtract 6” from the 8.5” which

leave 2.5” from the end to bend up to make the mark.

Tip:

Advanced benders can lay a tape measure next to the conduit and perform the

bending operations if the bend does not call for high degree of accuracy.

4.

Always use the proper size conduit bender for the conduit size being

bent. The conduit will not bend properly and/or will be damaged if a

mismatch of bender and conduit size is used. Place the bender onto the

tubing with the hook pointed towards the free end to be bent upwards.

Make sure the conduit is resting properly in the bender’s hook and

lineup the arrow symbol with the mark you placed on the tubing.

Bender Take Up Table

90° Stub-Up Bend

Conduit

Size

Stub

Height

Amount to subtract

from Measurement

½” EMT

5”

¾” EMT

and ½” Rigid

6”

1” EMT

and ¾” Rigid

8”

1-¼” EMT

and 1” Rigid

11”