Back to back bends – Klein Tools 56206 User Manual

Page 4

4

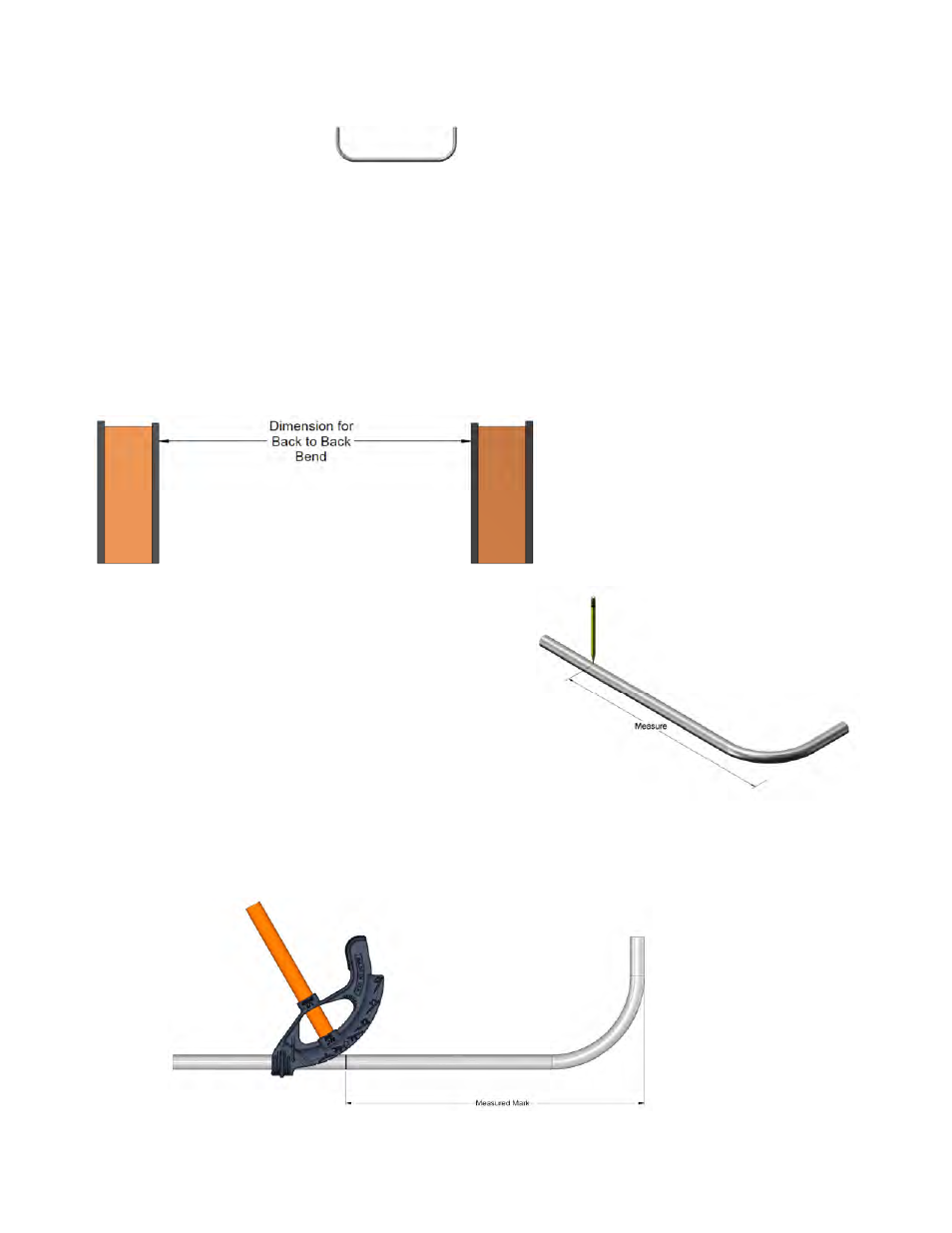

Back to Back Bends:

The back to back bend is the next style of bend that is needed while running electrical conduit. In reality

the concept is formulated by the need to know the distance from the back edge of a 90° bend to a fixed

point down the conduit to mark for other bend operations to meet the installation requirement. As you

will see it builds on the 90° stub bend and when done the most common use of this bend will look like

an elongated U.

You will need to know this bend method when you want to fit conduit between two parallel surfaces

such as two walls or joists while keeping the U’s outer edges of the legs touching the two surfaces. This

allows for proper anchoring and a nice clean appearance.

1.

Determine the distance between

the two parallel surfaces to get the

dimension for back to back bend.

2.

The first bend for the back to back bend is the 90°

stub-up bend. Follow the steps from the 90° Stub-

Up section to create the ideal bend for the

connection on the first side.

3.

From the back edge of the 90° stub-up bend,

measure the distance found in step 1 and make

your mark on the conduit.

4.

Place the bender on the conduit with the bender’s hook facing the free end of the tube to be

bent opposite the original bend side. Make sure the conduit is resting properly in the bender’s

cradle and lineup the Star Point Symbol with the mark you placed on the tubing.