Materials used in klein harnesses – Klein Tools Harnesses User Manual

Page 8

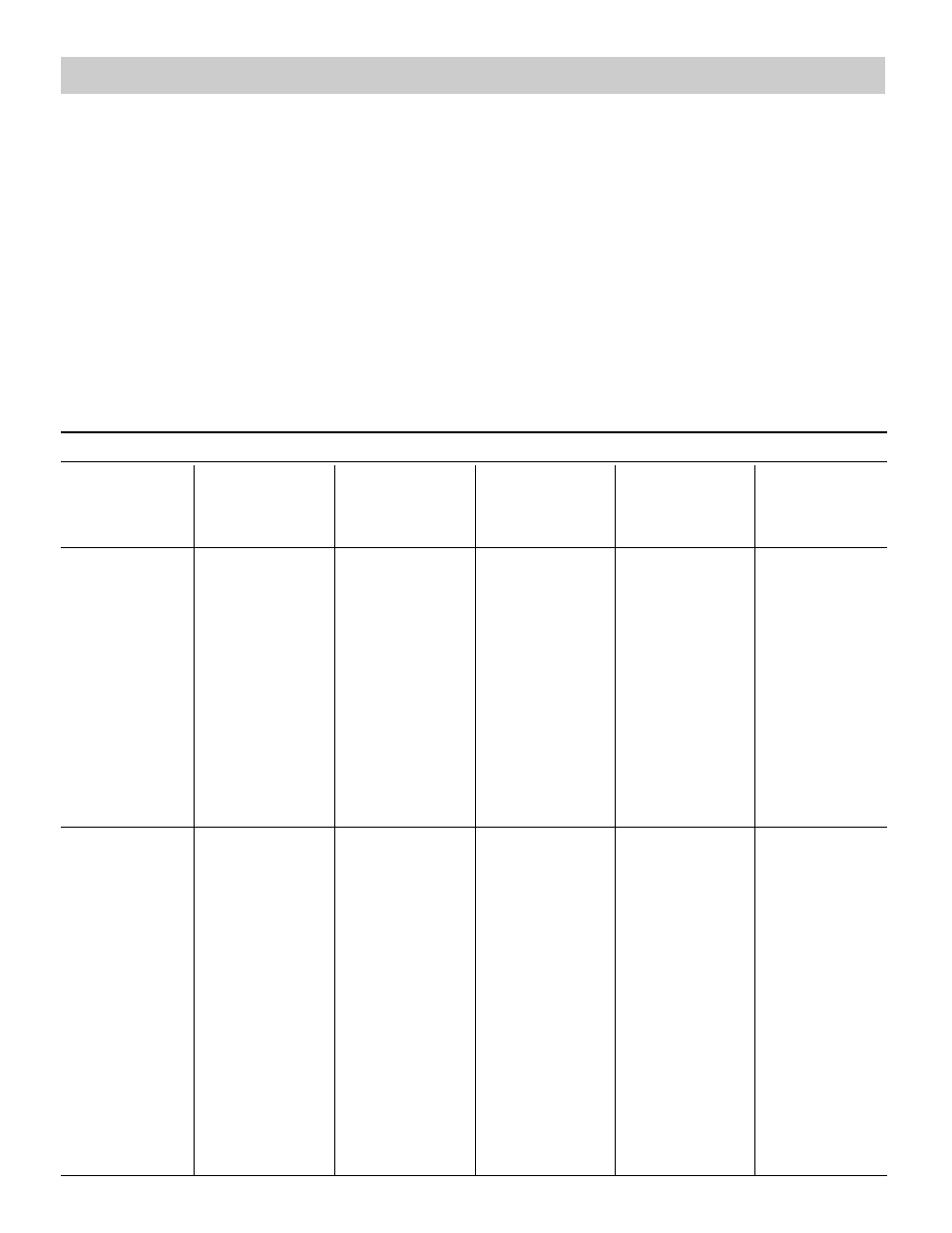

Type of

Material

Nylon

Exposure to

Excessive Heat

Poor resistance.

Becomes brittle,

has a shriveled

brown appear-

ance. Fibers will

break when

flexed.Weakens

at 300°F

(149°C).

Exposure to

Chemicals

Generally good

resistance,

except around

strong acids and

phenolic com-

pounds, which

cause it to

become brittle.

Exposure to

Molten Metal

or Flame

Poor resistance.

Strands fuse

together and

form hard shiny

spots. Has hard

and brittle feel.

Will not support

combustion.

Exposure to

Paints

or Solvents

Generally offers

good resistance.

However, paint

can penetrate

into the weave

and dry. This can

cause webbing to

become hard

and brittle and

can eventually

break the fibers.

Some solvents

may affect fibers

(see “Exposure

to Chemicals”).

Exposure

Near Live

Electrical Lines

& Equipment

Poor protection

(no dielectric

strength).

Provides no

protection against

exposure to live

electrical lines

or equipment.

Polyester

Poor resistance.

Fibers become

brittle and will

shrivel and turn

brown in color

and break when

flexed. Should

not be used

above 180°F

(82°C).

Good resistance

to most chemi-

cals, including

hydrochloric acid,

aqueous alkalies,

and many sol-

vents. Exposure

to incompatible

chemicals may

cause fibers to

change color and

texture, similar

to a brownish

smudge or smear.

Also will become

less elastic, with

transverse cracks

resulting from

bending.

Poor resistance.

Fiber strands

fuse together

and become

hard, brittle,

and shiny.

Generally offers

good resistance.

However, paint

can penetrate

into the weave

and dry. This can

cause webbing to

become hard

and brittle and

can eventually

break the fibers.

Some solvents

may affect fibers

(see “Exposure

to Chemicals”).

Poor protection

(no dielectric

strength).

Provides no

protection against

exposure to live

electrical lines

or equipment.

Nylon Webblng. Klein uses high-quality, commer-

cial-grade nylon. The web is impregnated with latex or

resin for extra durability.

Polyester Webbing. Used in certain Klein light-

weight harnesses. Polyester resists a wider variety of

chemicals than nylon does.

Softee™ Pads. These pads, which are stitched onto

many Klein belt components, are made of soft, non-

abrasive nylon with rounded edges for comfort.

Ultra-Hyde™. This highly durable, leather-like material

with high density and a “tight” surface is used primarily

for belt linings and pads. It is well suited for severe-

service environments. Klein does not use Ultra-Hyde

as the load-bearing material in OPE harnesses.

Drop-Forged Steel. Klein D-rings and snap hooks

are manufactured from drop-forged steel with a

corrosion-resistant finish and are tested to meet or

exceed applicable OSHA regulations.

Buckles. Klein Harnesses have single-tongue buckles,

friction-style buckles and/or easy-connect buckles. All

buckles are made of steel that is tested to meet or

exceed applicable OSHA regulations. Adjustments to

single-tongue buckles are made through holes that are

reinforced with solid brass grommets. Friction-style

buckles provide a continuous range of adjustment.

Easy-connect buckles also have friction slide adjusters

which hold straps in place, so the user does not

need to readjust for each use.

Physical Properties

Materials Used in Klein Harnesses

8