Kifco T40x1320 380,540 - 400,110 Operator Manual User Manual

Page 35

36

--Maintenance & Adjustment--

4. Now place the sleeve on the tube and push it on until it is flush with the cut end

of the tube.

5. Apply lubricant to the fitting and to the inside of the tube. The best lubricant is

liquid dishwasher soap. Now screw the fitting in until all the threads are in the

tube. Again, take care to keep the fitting straight.

6. Reach inside the coupling and remove any shreds of polyethylene created as a

result of cutting the thread in the tube. These may foul the sprinkler.

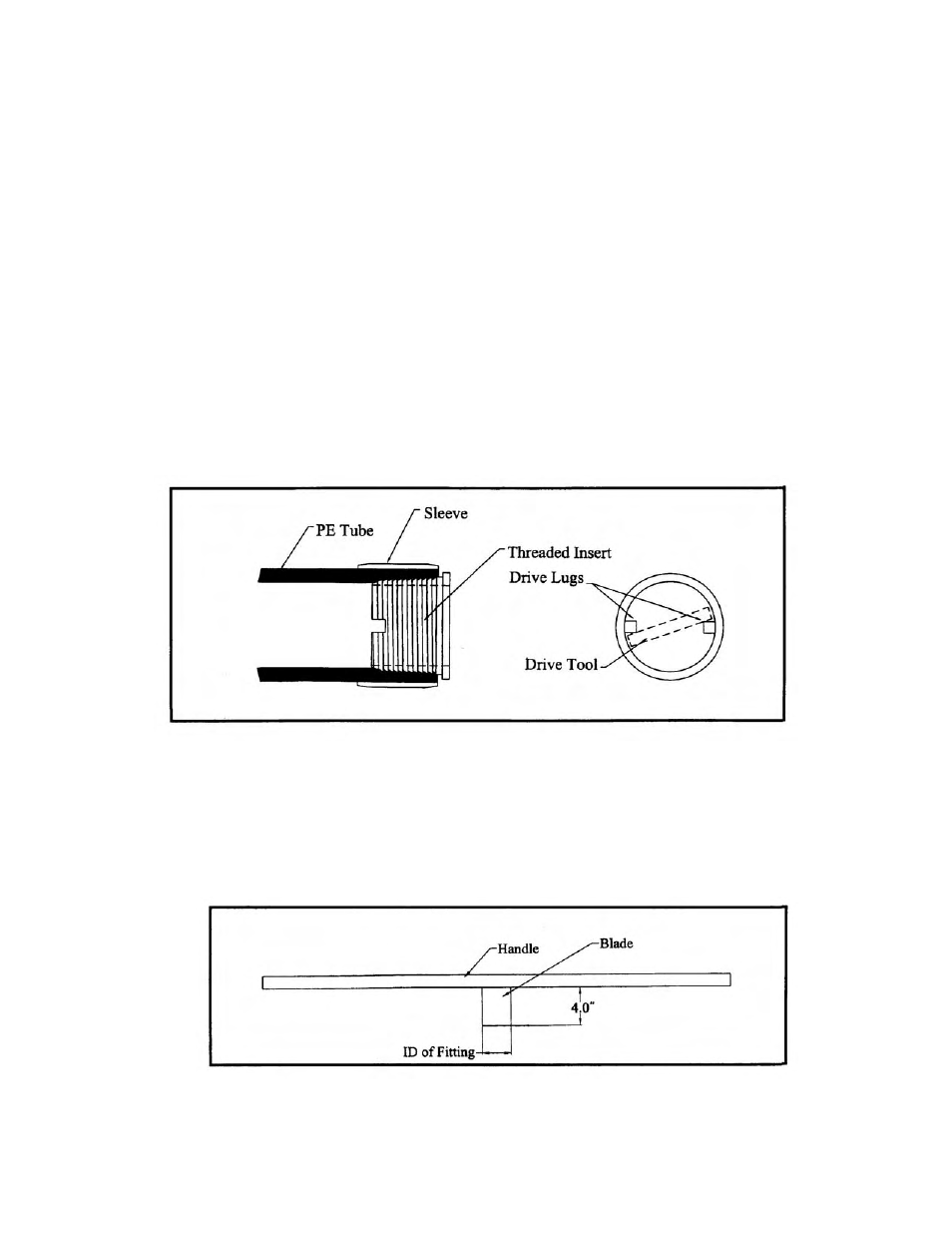

Tools used during installation depend on which fitting is being installed. To install a flange-

style fitting, use bar 5 or 6 feet long placed between two bolts inserted through the holes in

the flange. For the spool elbow, use a pipe and/or a large pipe wrench. For fittings with

drive lugs inside the fitting, a special installation tool is required. This tool is not provided

with the fittings.

Fittings that Require a Driver

The following diagram shows a typical driver for these fittings. The blade of the driver is

made from 3/8” x 4” plate. The width of the blade is the same or slightly less than the

diameter of the fitting. Weld the blade to a heavy steel bar or 1” schedule 80 water pipe

approximately 48” long.

Typical Driver Tool

- E37x1220 380,540 - 400,110 Operator Manual T37x1220 380,540 - 400,110 Operator Manual E33x1120 380,540 - 400,110 Operator Manual E30x1200 380,540 - 400,110 Operator Manual T33x1120 380,540 - 400,110 Operator Manual T30x1200 380,540 - 400,110 Operator Manual E30x980 380,540 - 400,110 Operator Manual T30x980 380,540 - 400,110 Operator Manual