Maintenance & adjustments – Kifco T40x1320 380,540 - 400,110 Operator Manual User Manual

Page 28

29

Maintenance & Adjustments

Danger! All power sources including water pumps must be disconnected and

secured before performing any maintenance or adjustments on your

water-Reel. Failure to disconnect all power sources before performing

maintenance or adjustments may result in machine damage, personal

injury, or death.

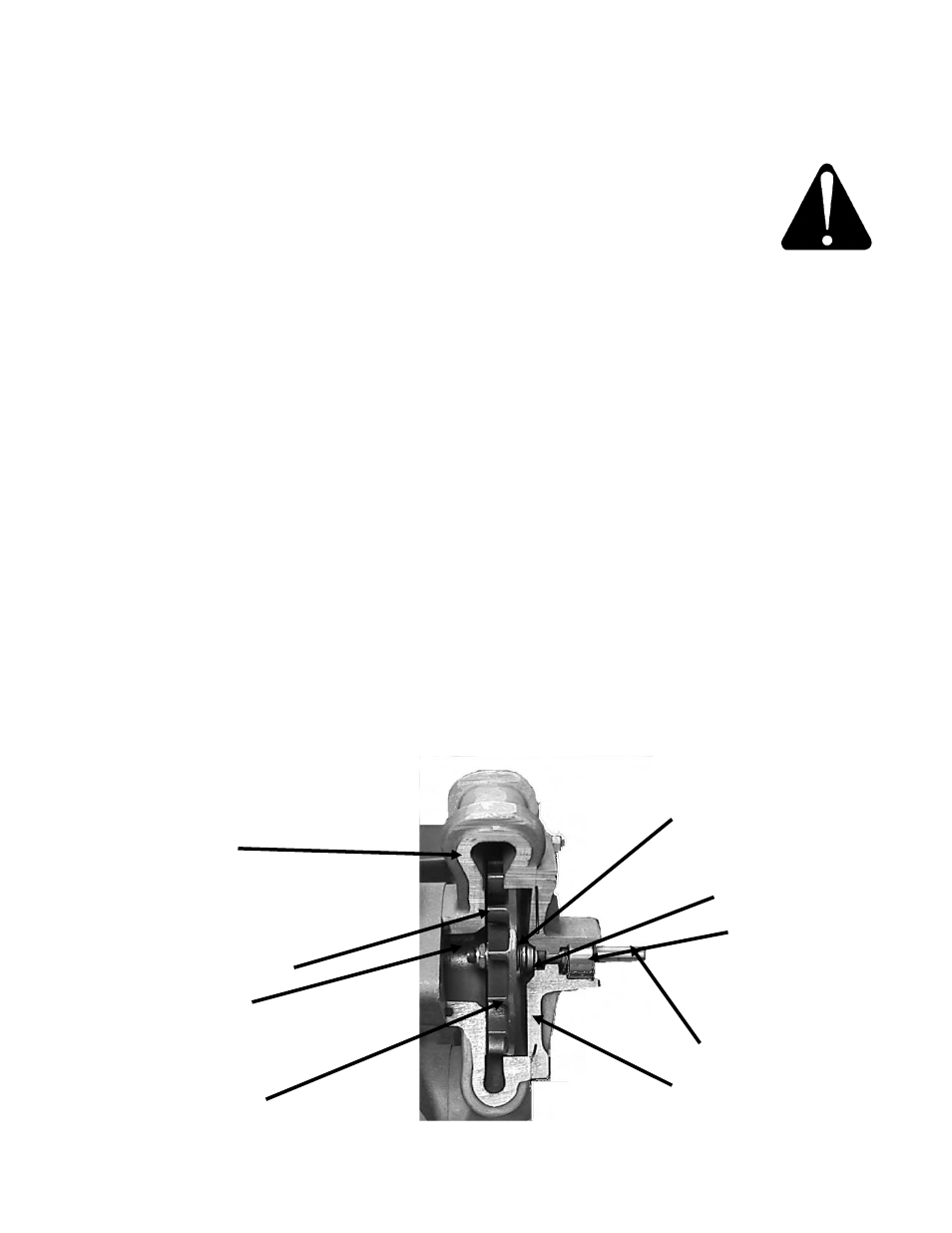

Runner Clearance:

The clearance between the runner vanes and the volute wear ring is set at

the factory at 0.045” which is satisfactory for most irrigation applications and

normally should not be changed. If runner adjustment becomes necessary:

A. Remove the faceplate, by removing eight 3/8” nuts from the bolt circle

B. Remove the 5/8” runner lock nut.

C. The runner is adjusted on the shaft by adding and removing spacers on

the backside of the runner. The 5/8” runner lock nut must be replaced

with a torque of 75 ft. lbs each time the spacers are added or removed.

First adjust the runner on the shaft (with the faceplate held in place and

without o-ring) until a slight metal to metal contact is heard as the runner is

turned. This establishes a zero clearance point. To set the clearance to

0.045” for clean water, remove one 0.045” spacer on the runner shaft.

Replace the 5/8” runner lock nut and torque to 75 ft. lbs. “Caution”

Excessive runner clearance decreases turbine power capability of the

water motor.

D. Replace the faceplate o-ring and 3/8” nuts.

Spacers

Volute

Mechanical Seal

Bearing

0.045” clearance

Lock Nut

Runner

Shaft

Faceplate

Runner

- E37x1220 380,540 - 400,110 Operator Manual T37x1220 380,540 - 400,110 Operator Manual E33x1120 380,540 - 400,110 Operator Manual E30x1200 380,540 - 400,110 Operator Manual T33x1120 380,540 - 400,110 Operator Manual T30x1200 380,540 - 400,110 Operator Manual E30x980 380,540 - 400,110 Operator Manual T30x980 380,540 - 400,110 Operator Manual