Kifco T40x1320 380,540 - 400,110 Operator Manual User Manual

Page 34

35

--Maintenance & Adjustment--

Installing Polyethylene Tube Fittings

Danger! Installing fittings or repairing polyethylene tube used on

your Water-Reel is hazardous! The tube has a shape memory from

being coiled on a reel and will coil back with great force as the tube

is released from one end or severed. This condition poses a

serious hazard to personnel and/or property. The tube must be

properly restrained anytime the tube or the tube fittings are being

repaired or replaced.

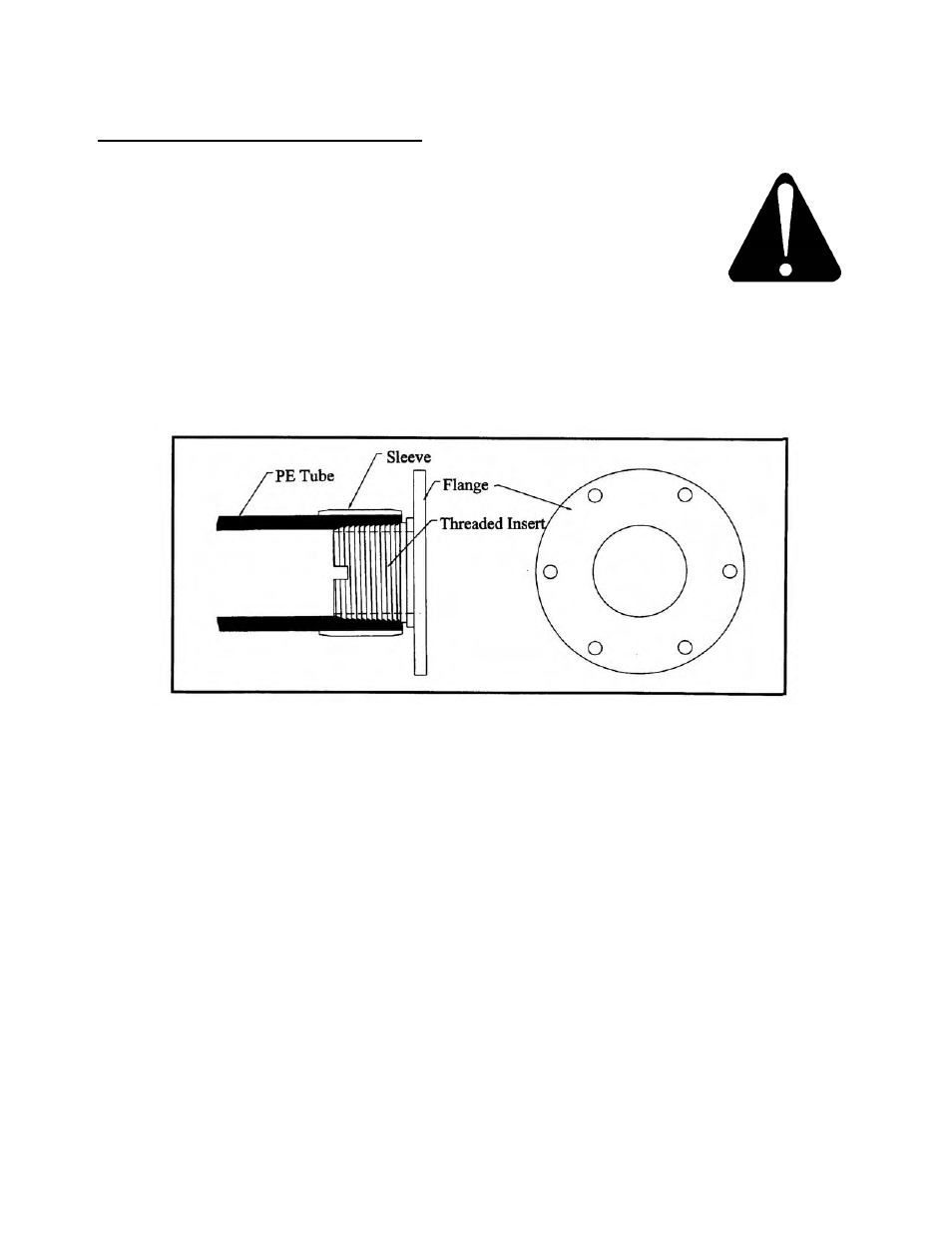

The fittings used on the ends of the polyethylene tube are made to screw into the tube

much the same way as a field repair of a hydraulic hose. A threaded insert screws into the

inside of the tube while an outer sleeve keeps the tube from enlarging as the insert is

installed. This provides a watertight seal and a secure grip on the tube for dragging.

Cutaway of Installed Sprinkler Cart Fitting

The following steps should be followed when installing fittings:

1. Secure the end of the tube by fastening it to a tractor or other heavy object. Cut

the tube. Make sure the cut on the end of the tube is square.

2. Chamfer the inside of the tube by using a sharp knife, wood rasp or a reamer.

Reamers are available for tubes 2.5 inch I.D. through 4.5 inch I.D. Your dealer

may have a reamer that you may rent or buy. The tube should be chamfered

evenly until approximately ¼ of the threaded portion of the fitting can be freely

pushed into the tube by hand without turning.

3. Before putting the sleeve on the outside of the tube, screw the threaded portion

of the fitting into the tube. Take care to keep the fitting and the tube aligned

while threading. This process cuts a partial thread in the tube which makes it

easier to keep the fitting straight during the final installation. Remove the fitting.

- E37x1220 380,540 - 400,110 Operator Manual T37x1220 380,540 - 400,110 Operator Manual E33x1120 380,540 - 400,110 Operator Manual E30x1200 380,540 - 400,110 Operator Manual T33x1120 380,540 - 400,110 Operator Manual T30x1200 380,540 - 400,110 Operator Manual E30x980 380,540 - 400,110 Operator Manual T30x980 380,540 - 400,110 Operator Manual