Kifco T40x1320 380,540 - 400,110 Operator Manual User Manual

Page 30

31

--Maintenance & Adjustments--

Level Wind Timing

Proper timing of the levelwind mechanism is essential for the successful operation of

the Water-Reel. Improper levelwind timing will result in mis-wrapped tube. Travel

will be interrupted because the auto compensation/shut-off bar will stop the drive

system in order to prevent damage to the irrigation tube.

Levelwind timing is set at the factory and normally does not need adjusting unless a

part has been removed, replaced or damaged

Warning! Do not continue to operate if the tube is not winding

properly! Operation of a machine that is not winding properly

may result in machine damage or personal injury.

IMPORTANT! If the machine levelwind appears to be malfunctioning, be positive

that the levelwind timing is really at fault before attempting to change the timing.

This machine was shipped from the factory with the tube wound on it. The levelwind

timing

was set at the factory prior to installing the tube. If the levelwind mechanism

has not been disassembled or the tube has not been removed & reinstalled, it is very

unlikely that the timing is wrong. If the tubing is loose on the spool the levelwind

system will appear to be out of time. See the section titled “Water-Reel Start-up &

Operation”.

Level Wind Timing

To re-time the levelwind, these steps must be followed:

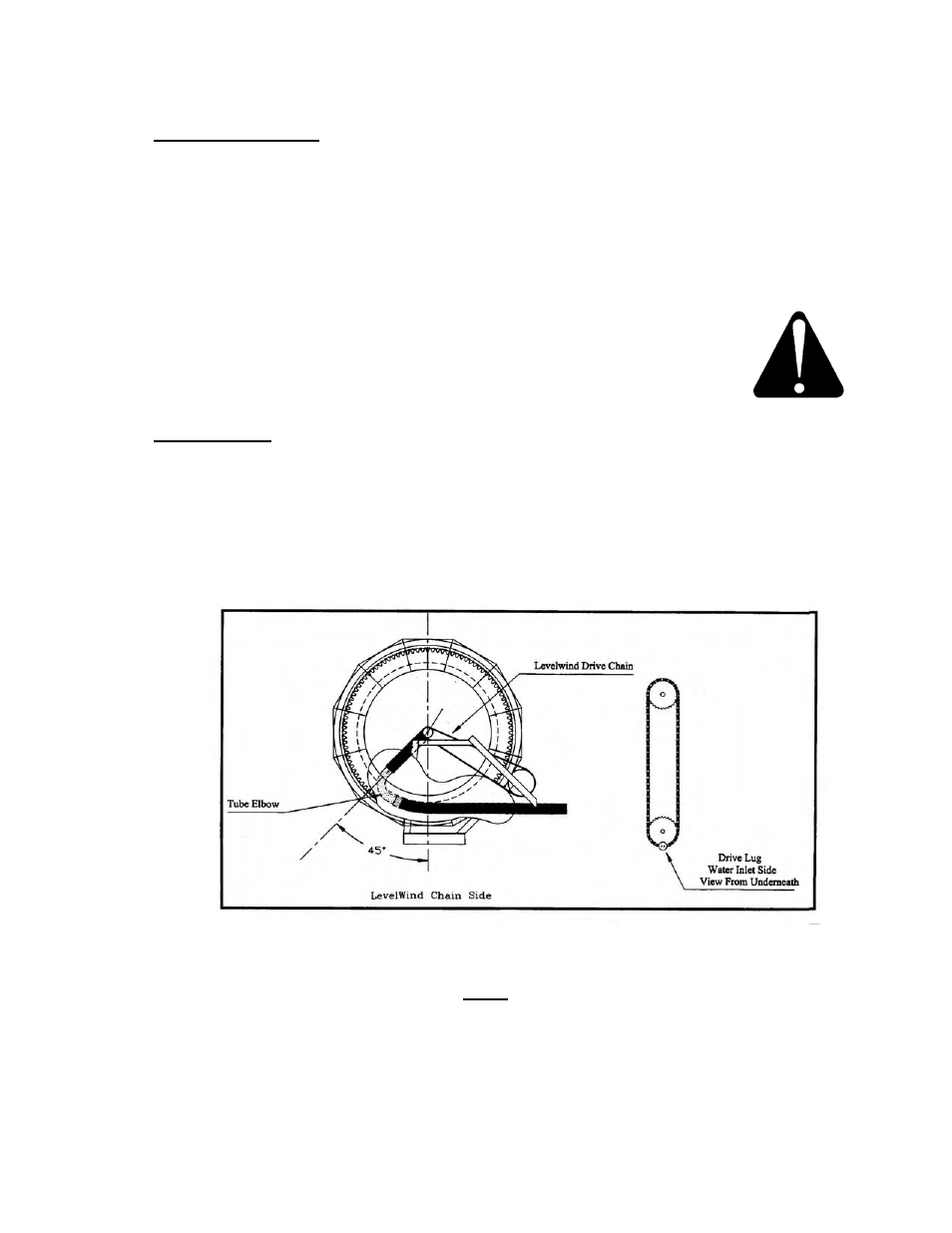

1. Pull all the irrigation tube out from the Water-Reel. The elbow to which the tube

is fastened must be 45 degrees behind the axle centerline on the bottom of the

spool (See diagram). Be especially careful not to pull the tube off the elbow.

- E37x1220 380,540 - 400,110 Operator Manual T37x1220 380,540 - 400,110 Operator Manual E33x1120 380,540 - 400,110 Operator Manual E30x1200 380,540 - 400,110 Operator Manual T33x1120 380,540 - 400,110 Operator Manual T30x1200 380,540 - 400,110 Operator Manual E30x980 380,540 - 400,110 Operator Manual T30x980 380,540 - 400,110 Operator Manual