JUMO 60.8425 Contact dial thermometer Data Sheet User Manual

Page 2

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone:

+49 661 6003-0

Fax:

+49 661 6003-607

E-mail:

Internet:

www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax:

+44 1279 635262

E-mail:

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax:

315-437-5860

E-mail:

Internet: www.jumousa.com

2011-11-08/00402234

Data Sheet 608425

Page 2/6

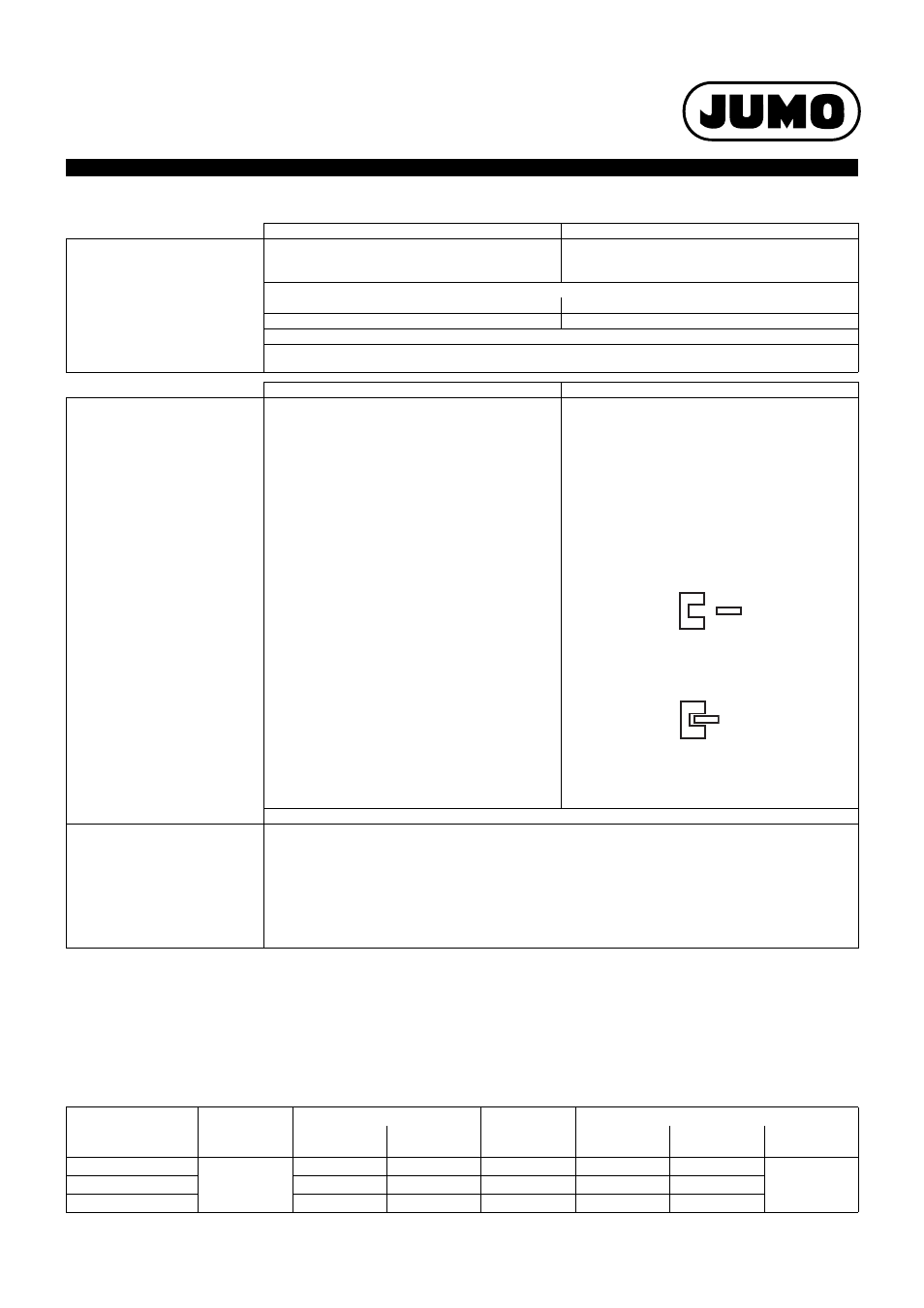

Standard

Extra code (TZ) 442

Electrical contact

Contact type

electromechanical slow-break contact

with single-pole make contacts

electromechanical magnetic snap-action contact

with single-pole make contacts

Contact rating

230 V AC/DC, +10/-15%, 48 — 63Hz, p.f = 1 (0.6)

max. 18 VA / 10 W

max. 50 VA / 30 W

Switching differential

≤ 0.5% of indication range

approx.2% of indication range

Switching point accuracy

±0.5% of indication range (referred to the switching point for rising temperature)

Switching reliability

To ensure maximum switching reliability, we recommend a minimum voltage of 24 V and a minimum current

of 20 mA

Electromechanical limit contact

Inductive limit contact

Switching output

01 to 11

30 and 31

The inductive limit contact is operated by a

contactless proximity switch. The sensor is a slot-

type initiator attached to the setpoint indicator. The

control flag is activated by the pointer.

If the control flag moves into the sensor gap, the

internal resistance increases (active area is damped:

initiator is high-resistance, relay is de-energized).

The switching amplifier of the control device

responds to the resulting change in current.

Switching action according to the

“active current principle”.

Control flag is not within the sensor air gap, relay is

energized:

Current drawn

≥ 3mA

(active area is clear, the oscillator is active).

Control flag is within the sensor air gap,

Relay is de-energized:

Current drawn

≤ 1mA

(active area is damped, no oscillation).

Inductive limit contact

as per Directive 94/9 EC (ATEX),

suitable for II 2 G EEx ia IIC T6

for switching sequence and diagrams: see order details

Secondary switched devices

For electromechanical limit detectors we recommend using Type MSR multi-function relays from:Wiebrock

Mess- und Regeltechnik GmbH, www.wiebrock.de.

These switching amplifiers increase the switching reliability and switching capacity of slow-break and

magnetic snap-action contacts, and reduce their contact loading.

Unintended switching of the limit contact (caused by vibration) can be considerably reduced by using a

drop-out delay.

With inductive limit detectors, you can use the transistor relay:

Type KFA6-SR2-Ex...W (II (1) G D

[EEx ia] IIC)

from Pepperl & Fuchs (www.pepperlfuchs.de).

Intrinsic safety II 2 G EEx ia IIC T6 can only be ensured if this transistor relay is used.

Note:

Physical and toxic features of the expansion means, which could emerge in the event of a measuring system break.

1)

There is currently no statement by the health authority concerning hazards to health in the event of short-term exposure and low concentration, e.g. measuring

system

break.

Control range with

scale limit value

Hazardous re-

actions

Fire and explosion hazard

hazardous to

waters

Information about toxicology

Ignition tem-

perature

Explosion limit

irritant

dangerous to

health

toxic

<

+200°C

no

+ 355°C

0,6 - 8 V%

yes

yes

1)

no

≥

200°C

≤ +350°C

+ 490°C

- -

yes

yes

1)

> 350°C ≤ +500°C

no

no

no

no

no