Description, Standard functions – JUMO 705060 mTRON T - Multifunction Panel 840 Data Sheet User Manual

Page 2

2014-08-22/00529113

Data sheet 705060

Page 2/13

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone:

+49 661 6003-0

Fax:

+49 661 6003-607

E-mail:

Internet:

www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax:

+44 1279 635262

E-mail:

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax:

315-437-5860

E-mail:

Internet: www.jumousa.com

Description

The multifunction panel 840 can be used by the user to configure, parameterize, monitor, and operate the measuring, control and automation sys-

tem. A recording function, as known from the JUMO paperless recorders, is available as an option. The JUMO mTRON T system bus supports

one multifunction panel; the prerequisite for using the multifunction panel is an installed central processing unit.

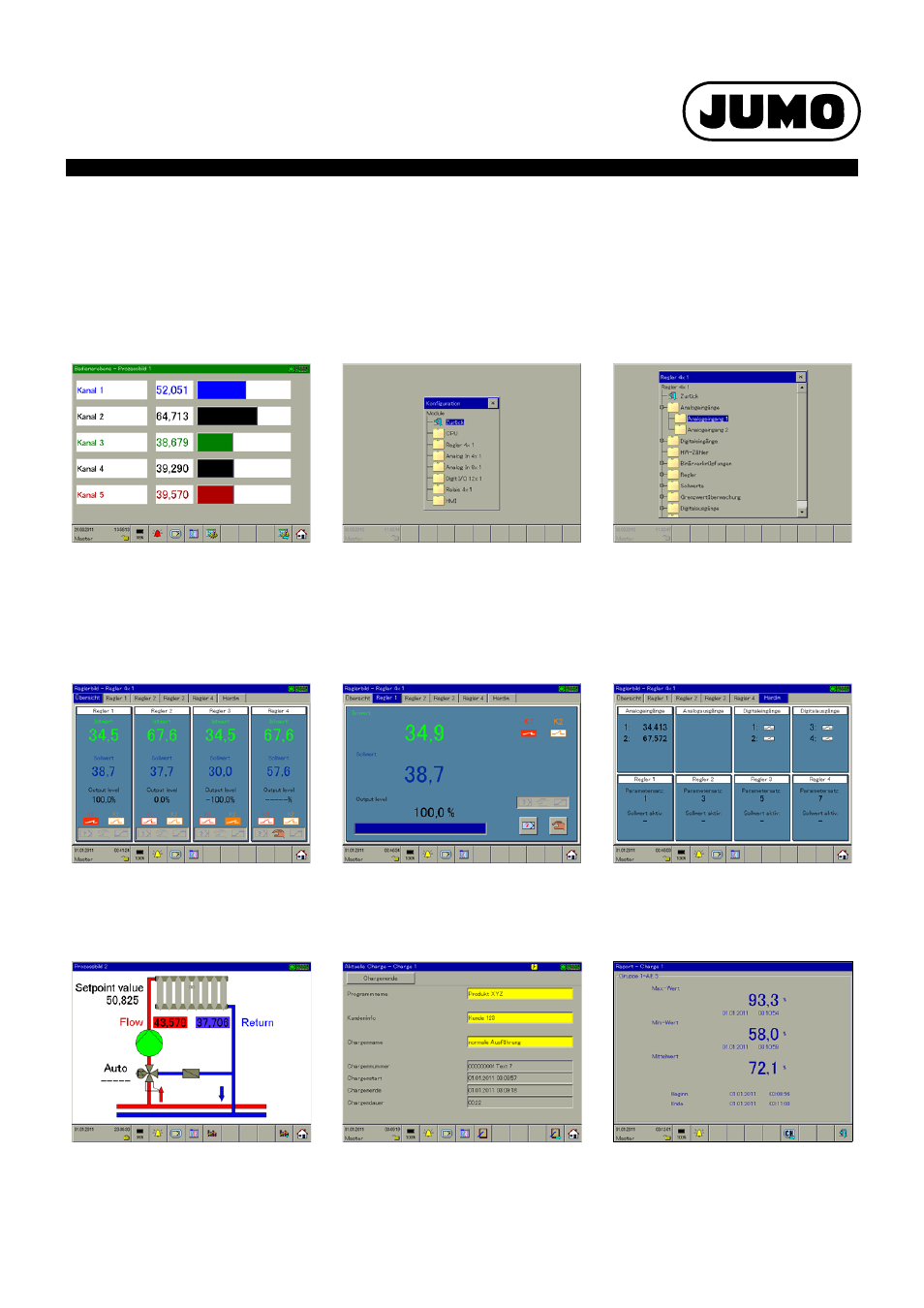

Standard functions

Start screen (e. g. process screen)

• Selectable start screen

• Operation via symbol bar

• Screen switch-off

• User-specific visualizations

• User level

Configuration of the modules

• Online configuration of all input/output modules

Example: Controller module

• Inputs/outputs

• Controller type

• Self-optimization

• Special functions for the plastics processing

industry

• Setpoint values

• Limit value monitoring

Visualization of the controller channels

• Up to four controller channels per controller

module

• Overview of the active control variables

• Online editing of the setpoint values

Single controller channel

• Overview of the active control variables

• Online editing of the setpoint values

• Manual start of the self-optimization and the

manual mode

Controller module

• Overview of the active inputs and outputs

• Overview of the active control variables

Process mask

• 18 customer-specific process screens

• Freely configurable display (via setup program)

of process values

Batch protocoling

• Simultaneous recording of nine batches

• Toggling between current and completed batch

protocols

• Batch texts are readable via interface and bar

code scanner (among other methods)

Completed batch protocols

• Graphical data evaluation

• Numerical data evaluation