Operation, Deinstallation, Electrical connection – INFICON MPG40x ATM to Ultra-High Vacuum Gauge User Manual

Page 3: Gas type dependence, Ignition delay, Adjusting the gauge

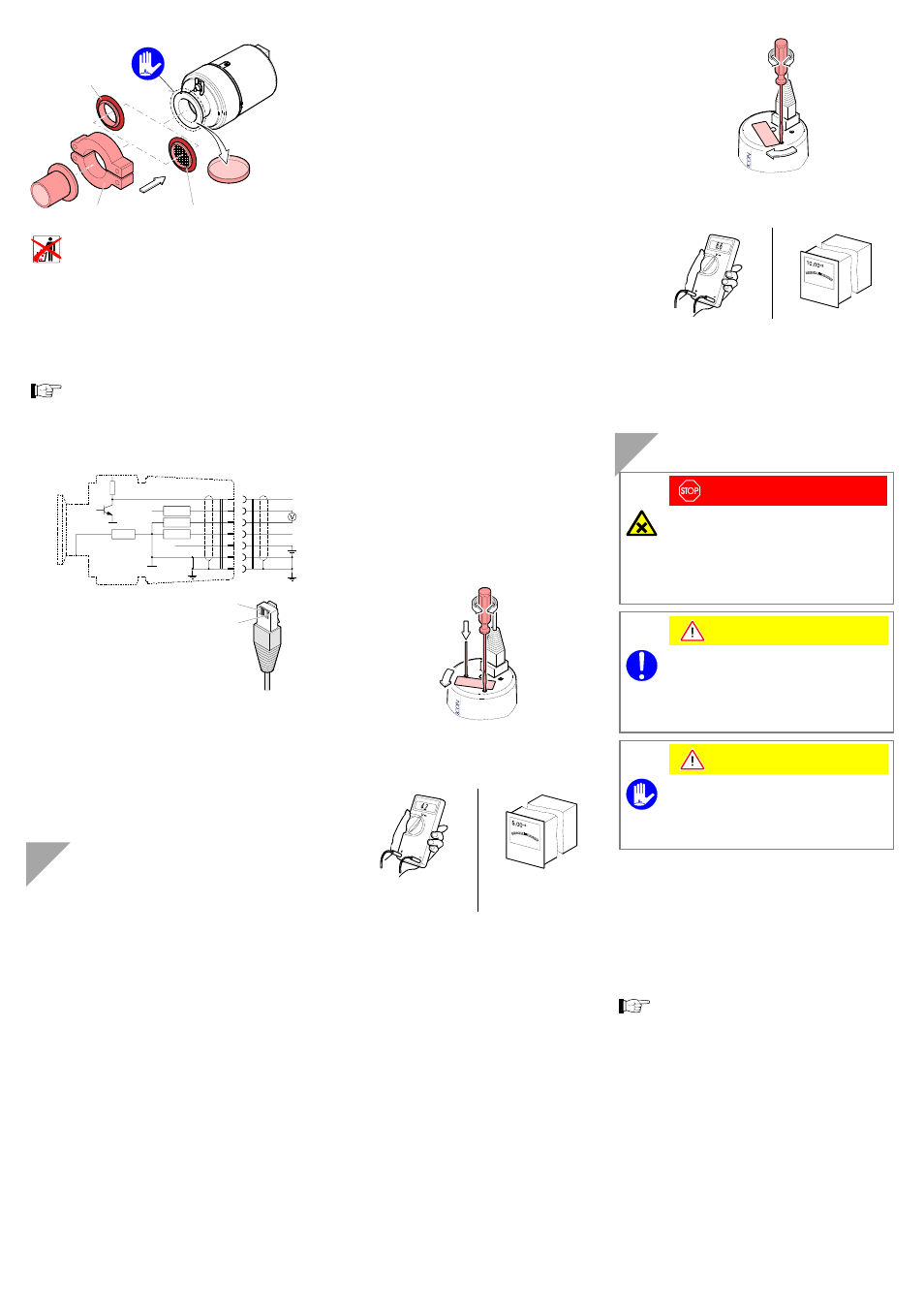

Seal with

centering ring

Clamp

or

Seal with centering ring

and filter

Protective lid

Keep the protective lid.

If adjustment should be possible after the gauge has been

installed, be sure to install it so that potentiometers

and

(

→

"Adjusting the Gauge").

Electrical Connection

Make sure the vacuum connection is properly

made (

→ "Vacuum Connection").

If no sensor cable is available, make one according to

the following diagram.

Electrical connection

Pin 1

Supply (15 … 30 VDC)

Pin 2

Supply common

Pin 3

Signal output

(measuring

signal)

Pin 4

Identification

Pin 5

Signal common

Pin 6

Status

Pin 7, 8 n.c.

8 poles FCC-68

1

8

10

10

Ident

3

5

4

1

2

–

+

–

+

6

10 k

Signal

Connect the gauge to the controller using the sensor

cable.

Operation

When the supply voltage is applied, the measuring signal is

available between pins 3 and 5. Over the whole measure-

ment range, the measuring signal is output as a logarithm of

the pressure (measuring signal vs. pressure

→ "Technical

Data").

Allow for a stabilizing time of

≈10 minutes. Once the gauge

has been switched on, permanently leave it on irrespective of

the pressure.

• The Pirani measurement circuit is always on.

• The cold cathode measurement circuit is controlled by the

Pirani circuit and is activated only at pressures

<1×10

-2

mbar.

Gas Type Dependence

The measurement value depends on the type of gas being

measured. The value displayed is accurate for dry air, O

2

,

CO and N

2

. It can be mathematically converted for other

gases (

→ "Technical Data").

If the gauge is operated in connection with an INFICON

vacuum gauge controller, a calibration factor can be entered

for correction of the reading.

Ignition Delay

When cold cathode measurement systems are activated

upon switching the gauge on, an ignition delay occurs, which

is typically:

10

-5

mbar

≈ 1 second

10

-7

mbar

≈ 20 seconds

5×10

-9

mbar

≈ 2 minutes

As long as the cold cathode measurement circuit has not yet

ignited, the measurement value of the Pirani is output as

measuring signal ("Pirani underrange" is displayed for pres-

sures <5×10

-4

mbar).

Adjusting the Gauge

The gauge is factory-calibrated. If used under different clima-

tic conditions, through extreme temperatures, aging or conta-

mination, and after exchanging the sensor, the characteristic

curve can be offset and readjustment may become

necessary.

The cold cathode measurement circuit, which is dominant for

low pressures (<1×10

-3

mbar), is factory-calibrated. By way of

contrast, the Pirani measurement circuit can be adjusted.

Any adjustment has a negligible effect on the pressure range

between approx. 10

-2

mbar and 10

2

mbar.

If you are using a seal with centering ring and filter,

check that they are clean or replace them if necessary

(

→ "Deinstallation").

Activate the gauge.

Evacuate it to p << 10

-4

mbar and wait at least

10 minutes.

Turn the nameplate counter-clockwise until the me-

chanical stop is reached.

While depressing the tactile switch with a cylindrical

pin (ø

≈

3 mm), adjust the

means of a 1.5 mm screwdriver …

… to 4.20 V

or

… to 5×10

-4

mbar

After that, turn the

potentiometer counter-

clockwise by

1/3

of a turn.

Vent the gauge with air or nitrogen to atmospheric

pressure, and wait at least 10 minutes.

Turn the nameplate clockwise until the mechanical stop

is reached.

Using the 1.5 mm screwdriver, adjust the

potentiometer …

… to 8.60 V

or

… to 1×10

3

mbar

Turn the nameplate back to its original position (it

catches).

Deinstallation

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with one's

bare hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

Vent the vacuum system.

Put the gauge out of operation and unplug the sensor

cable.

Remove the gauge from the vacuum system and place

the protective lid.

When deinstalling a CF flange connection, it can be

advantageous to temporarily remove the electronics

and the magnet unit (

→"Installation").