Operation, Power connection (hpg400), Gas type dependence – INFICON HPG400 ATM to High-Vacuum Gauge User Manual

Page 3: Measuring range, Selecting the changeover threshold, Adjusting the gauge (hpg400), Display

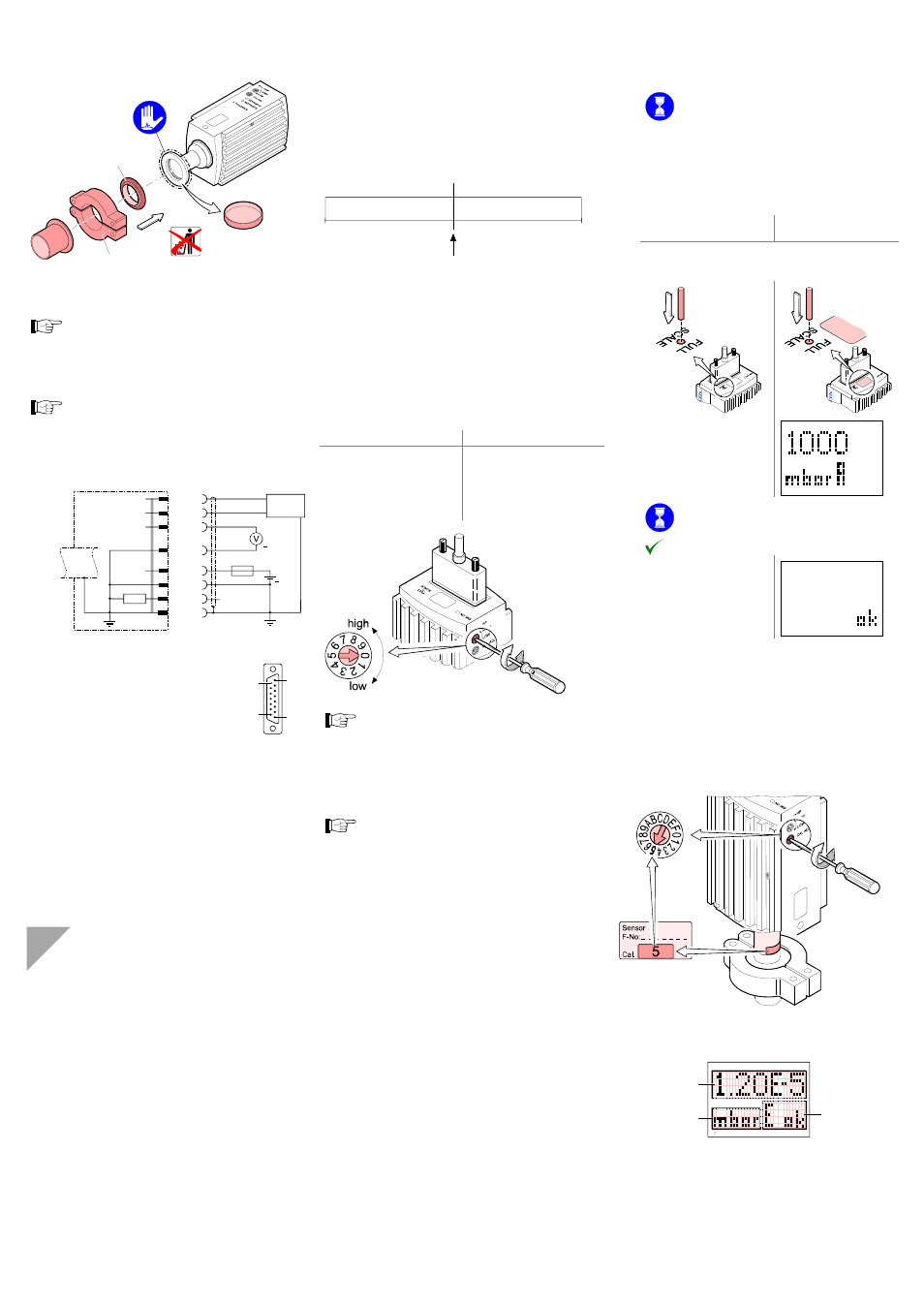

Remove the protective lid and install the product to the

vacuum system.

Keep protective lid

Clamp

Seal with

centering ring

Power Connection

(HPG400)

The following information on the electrical connec-

tion as well as the wiring diagram apply to HPG400

only (

→ [1] and [2] for details on the electrical

connection and additional functions of HPG400-SD

and -SP).

Make sure the vacuum connection is properly made

(

→ "Vacuum Connection").

If no sensor cable is available, make one according to

the following diagram.

Electrical connection

Pin 2 Signal output (measuring signal) 0 … +10 V

Pin 5 Supply common, GND

Pin 8 Supply +24 VDC

Pin 10 Gauge identifcation

Pin 12 Signal common, GND

Pin 13 RS232C, TxD

Pin 14 RS232C, RxD

Pin 15 Shielding, housing, GND

Pins 1, 3, 4, 6, 7, 9 and 11

are not connected internally.

8

9

1

15

TxD

HPG400

56kΩ

RxD

Measuring signal

+Ub

13

14

2

12

8

5

15

+

1.25AT

Identification

10

RS232C

+

24 V

D-Sub, 15-pin

female

soldering side

Connect the sensor cable to the gauge.

Secure the cable connector with the lock screws.

Connect the sensor cable to the controller.

Operation

When the voltage is supplied, the measuring signal is avail-

able between pins 2 (+) and 12 (–) (Relationship Measuring

Signal – Pressure

→ "Technical Data" and [1]).

HPG400-SD and -SP can also be operated via the corre-

sponding fieldbus interface (DeviceNet or Profibus) (

→ [1]

and [2]) for further details and functions).

Allow for a stabilizing time of

≈10 minutes. Once the gauge

has been switched on, permanently leave it on irrespective of

the pressure.

Gas Type Dependence

The measurement value is gas dependent. The displayed

reading applies to dry air, O

2

and N

2

. For other gases, it has

to be converted (

→ "Technical Data" and [1]).

Measuring Range

The HPG400 covers the measuring range

2×10

-6

mbar ... 1000 mbar.

• The Pirani part permanently monitors the pressure.

• The hot cathode part (controlled by the Pirani) is only

switched on when the pressure drops below the change-

over threshold. The hot cathode will be ready for operation

after a few seconds heating time, when the

lamp is lit.

• When the pressure rises above the changeover threshold,

the hot cathode is switched off and the

turns off.

In the upper pressure range, the Pirani reading and in the

lower pressure range, the hot cathode reading is output.

1000 mbar

2 ×

10

-6

mbar

Hot cathode HP

Pirani

5×10

-2

mbar ... 1 mbar user-

definable changeover threshold

Selecting the Changeover Threshold

The HPG400 has five user-definable changeover thresholds.

It is thus possible to prevent the changeover range from be-

ing situated within the process pressure range. The factory

setting of the threshold is 1 mbar. Another changeover

threshold can be selected via the

↔ HP> switch. Since

the contamination of the hot cathode part is reduced at low

pressures, the lowest possible changeover threshold should

be selected.

Switch position (

↔ HP>)

Changeover threshold

0 or 1

1 mbar (factory setting)

2 or 3

5×10

-1

mbar

4 or 5

2×10

-1

mbar

6 or 7

1×10

-1

mbar

8 or 9

5×10

-2

mbar

Since the switch position is only polled upon activa-

tion of the gauge, the changeover threshold should

be selected before the gauge is turned on.

Adjusting the Gauge

(HPG400)

The adjustment of HPG400-SD and -SP (

→ [1]

and [2]) is slightly different from the procedure for

HPG400, which is described below.

The gauge is factory calibrated. If used under different cli-

matic conditions, at extreme temperatures, through aging or

contamination and after exchanging the sensor, the char-

acteristic curve can be offset and readjustment can become

necessary. Only the Pirani element can be adjusted and only

at atmosphere.

Readjustment becomes necessary if

• at atmosphere the output voltage is <9.75 V or the display

reading is • when venting the vacuum system, the output voltage reaches 9.75 V before the measured pressure has (For more details → [1], "Maintenance, Repair"). Adjustment of the Pirani part under high vacuum -3 mbar is reached for the first time. Adjustment of the Pirani part at atmospheric pressure: Put the gauge into operation. Operate the gauge for ≈10 minutes at atmos- pheric pressure. If the gauge was operated ≈30 minutes is to be expected (gauge temperature = environmental temperature). Adjust the gauge HPG400 without display 353-520 353-522 HPG400 with display 353-521 353-523 Insert a pin ( ≈ш1.3Ч50mm) through the opening for at least 5 seconds. — ≈10 s Automatic adjustment in progress. Adjustment completed. — Adjusting the Calibration Setting of the The sensor is factory calibrated. The calibration setting of the Display (HPG400 with part numbers 353-521 and 353-523) Pressure reading Pressure unit Status

reached atmosphere (Gauges with display will show the

error "5" at atmosphere (Pirani sensor warning)).

conditions:

The Pirani part is automatically adjusted by the hot cathode

part when the gauge is activated and the pressure range

1 … 3×10

within the hot cathode range, a cooling-down

time of

Hot Cathode Part

hot cathode range 0 … F is printed on the label. Correct this

value with the

the sensor. Before operating the gauge for the first time or

after replacing the sensor, check the calibration value setting

and adjust it if necessary.