Operation, Deinstallation, Power connection (bcg450) – INFICON BCG450 ATM to Ultra-High Vacuum Triple Gauge User Manual

Page 3: Gas type dependence, Adjusting the gauge, Display

Caution

Caution: vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

The gauge may be mounted in any orientation. To

keep condensates and particles from getting into the

measuring chamber, preferably choose a horizontal

to upright position.

The gauge is supplied with a built-in grid. For poten-

tially contaminating applications and to protect the

electrodes against light and fast particles, installa-

tion of

• the optional baffle or

• the optional centering ring with baffle

is recommended (

→ [1]).

Remove the protective lid and install the product to the

vacuum system.

We recommend to install the gauge without applying

vacuum grease.

Protective lid

Clamp

Seal with centering ring

Keep the protective lid.

Power Connection

(BCG450)

The following information on the electrical con-

nection as well as the wiring diagram applies to

BCG450 only (

→ [1] and [2] for details on the

electrical connection and additional functions of

BCG450-SD and -SP).

Make sure the vacuum connection is properly made

(

→ "Vacuum Connection").

n

If no connection cable is available, make one according

to the following diagram.

TxD

RxD

Degas

42 k

Ω

13

14

7

8

2

12

5

15

1.25 AT

24V

Degas

Ident.

RS232

10

-

-

-

+

-

Measuring

signal

1

4

8

9

1

15

D-Sub,15-pin,

female,

soldering side

Atmospheric pres-

sure reached 1)

Common (power GND 24V supply)

Ground (housing, vacuum connection)

Electrical connection

Pin 1

Relay "Atmosphere

reached", n. o. contact

1)

Pin 2

Measuring signal output

0 … +10.13 V

Pin 4

Relay "Atmosphere

reached", com contact

1)

Pin 5

Supply common

0 V

Pin 7

Degas on, active high

0 V/+24 V

Pin 8

Supply

+24 V

Pin 10

Gauge identification

Pin 12

Measuring signal common

Pin 13

RS232, TxD

Pin 14

RS232, RxD

Pin 15

Do not connect

Pins , 3, 6, 9 and 11 are not connected internally.

1)

Detailled information on the atmosphere switching

function and the "Atmosphere reached" relay

→ [1].

o

Connect the sensor cable to the gauge.

p

Secure the cable connector with the lock screws.

q

Connect the sensor cable to the controller.

Operation

When the supply voltage is applied, the measuring signal is

available between pins 2 (+) and 12 (–) (Relationship Meas-

uring Signal – Pressure

→ "Technical Data" and [1]).

BCG450-SD and -SP can also be operated via the corre-

sponding fieldbus interface (DeviceNet or Profibus,

→ [1]

and [2] for further details and functions).

Allow for a stabilizing time of

≈10 minutes. Once the gauge

has been switched on, permanently leave it on irrespective of

the pressure.

Gas Type Dependence

Pressure range

Measuring

principle

Gas type

dependence

10 … 1500 mbar

capacitance

diaphragm

sensor

independent of gas

type, no correction

required

1 … 10 mbar

capacitance

diaphragm

sensor and

Pirani sensor

crossover range

2×10

-2

… 1 mbar

Pirani sensor

1)

5Ч10

-3

…

2Ч10

-2

mbar

Pirani sensor

and

hot cathode

ionisation

sensor (BA)

crossover range

5Ч10

-10

…

5Ч10

-3

mbar

hot cathode

ionisation

sensor (BA)

1)

1)

→ Table "Technical Data, Calibration factors"

Adjusting the Gauge

The gauge is adjusted automatically (adjustment of the

atmosphere switching function (atmosphere sensor)

→ [1]).

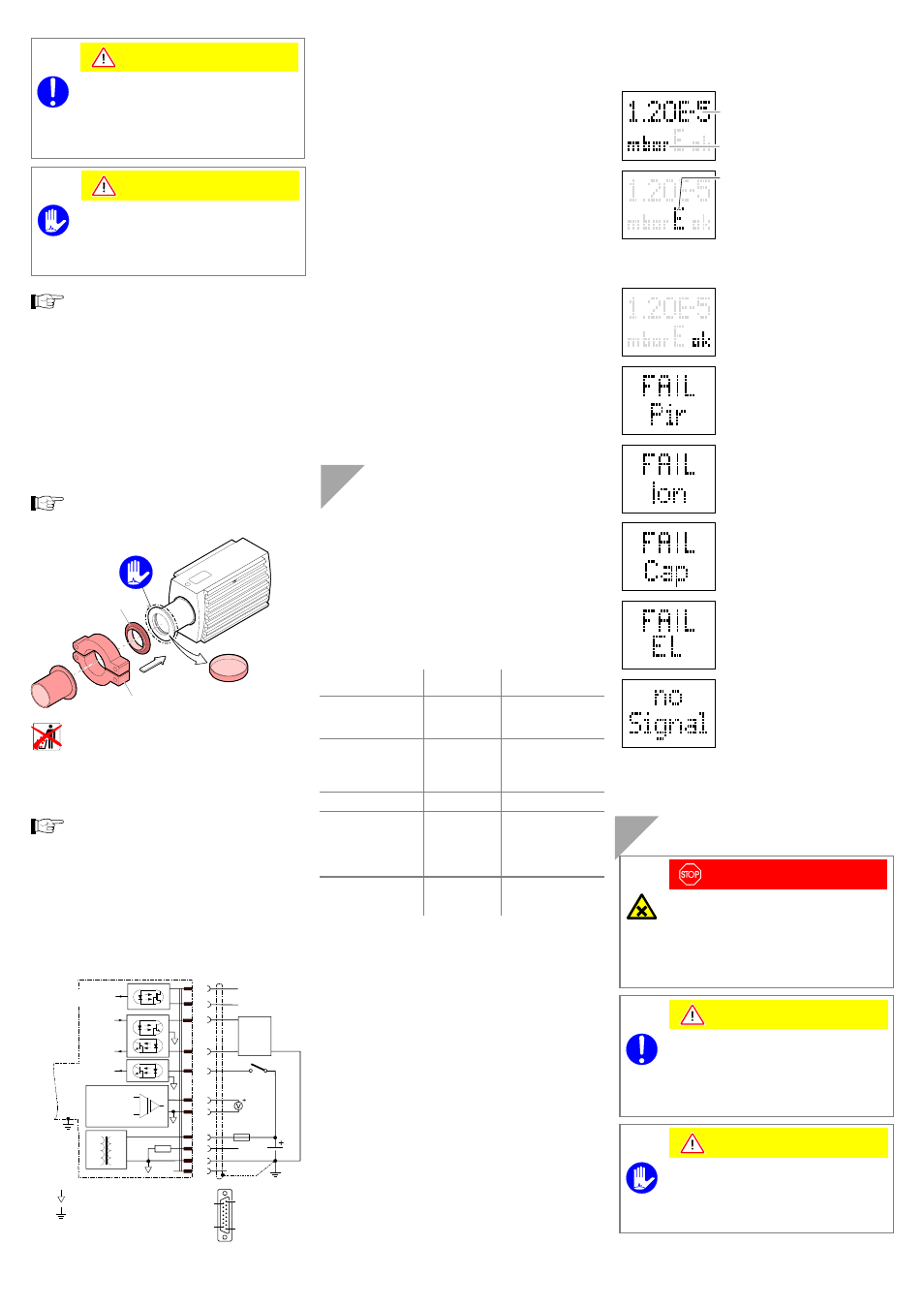

Display

(BCG450 with part numbers 353-552 and 353-553)

Pressure reading

Pressure unit

Function display

(none) Pirani operation

E

Emission 25

μA

E

.

Emission 5 mA

D

Degas

Error display:

No error

(green background illumination)

Pirani sensor error

(red background illumination)

BA sensor error

(red background illumination)

Diaphragm sensor error

(red background illumination)

EEPROM error

(red background illumination)

Internal data connection failure

(red background illumination)

Deinstallation

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.