Installation, Measuring signal vs. pressure, Gas type dependence – INFICON BCG450 ATM to Ultra-High Vacuum Triple Gauge User Manual

Page 2: Vacuum connection, P = 10, C × pressure indicated

Atmosphere switching

function (relay "Atmosphere

reached")

BCG450

BCG450-SD/-SP

Atmospheric pressure

threshold programmable via

serial interfaces (

→ [1])

threshold value programma-

ble via RS232 (default value

99%)

threshold value programma-

ble via fieldbus interfaces

(

→ corresponding communi-

cation protocols).

RS232C interface (BCG450)

Data rate

Data format

Connector

9600 Baud

binary

8 data bits

one stop bit

no parity bit

no handshake

→ "Power Connection"

Further information on the RS232C interface

→ [1]

Display (353-552, 353-553)

LCD matrix, 32×16 pixels

Background illumination

two colors red/green

Dimensions

16.0 mm × 11.2 mm

Pressure units

mbar (default), Torr, Pa

(Selecting the pressure unit

→ [1])

Supply

DANGER

The gauge must only be connected to power

supplies, instruments or control devices that

conform to the requirements of a grounded pro-

tective extra-low voltage (SELV). The connection

to the gauge has to be fused

1)

.

Voltage at gauge

+24 VDC (+20 … +28 VDC)

(ripple

≤2 V

pp

)

2)

Power consumption

Standard

Degas

Emissions start (200 ms)

≤0.5 A

≤0.9 A

≤1.4 A

Fuse required

1)

1.25

AT

Power consumption

≤18 W (BPG450)

Electrical connection

D-Sub, 15-pin, male

Sensor cable

shielded, number of con-

ductors depending on the

functions used (max.

15 conductors plus shield-

ing).

Cable length (24 VDC

(conductor cross-section)

≤35 m (0.25 mm²)

≤50 m (0.34 mm²)

≤100 m (1.0 mm²)

For operation with

RS232C interface

≤30 m

Materials on the vacuum side

Housing, supports,

screens

Feedthroughs

Insulator

Cathode

Cathode holder

Pirani element

Diaphragm

Sensor electrodes

stainless steel

NiFe nickel plated

glass

iridium, yttrium oxide (Y

2

O

3

)

molybdenum

tungsten, copper

ceramic (Al

2

O

3

)

SnAg

Internal volume

DN 25 ISO-KF

DN 40 CF-R

≈24 cm

3

≈34 cm

3

Maximum admissable

pressure

5 bar (absolute)

Admissible temperatures

Storage

Operation

Bakeout

–20 … +70 °C

0 … +50 °C

+80 °C (at vacuum connec-

tion, without electronics unit,

horizontally mounted)

Relative humidity

Year’s mean

During 60 days

≤65% (not condensable)

≤85% (not condensable)

Use indoors

only

altitude up to 2000 m NN

Mounting orientation

any

Type of protection

IP 30

1)

INFICON gauge controllers fulfill these requirements.

2)

Measured at the sensor cable connector (consider the voltage

drop on the sensor cable).

Dimensions [mm]

DN 25 ISO-KF

DN 40 CF-R

4-40UNC 2B

4-40UNC 2B

Weight

353-550 / -552 / -561

353-551 / -553

353-554 / -557 / -562

353-556 / -558

≈305 g

≈565 g

≈445 g

≈710 g

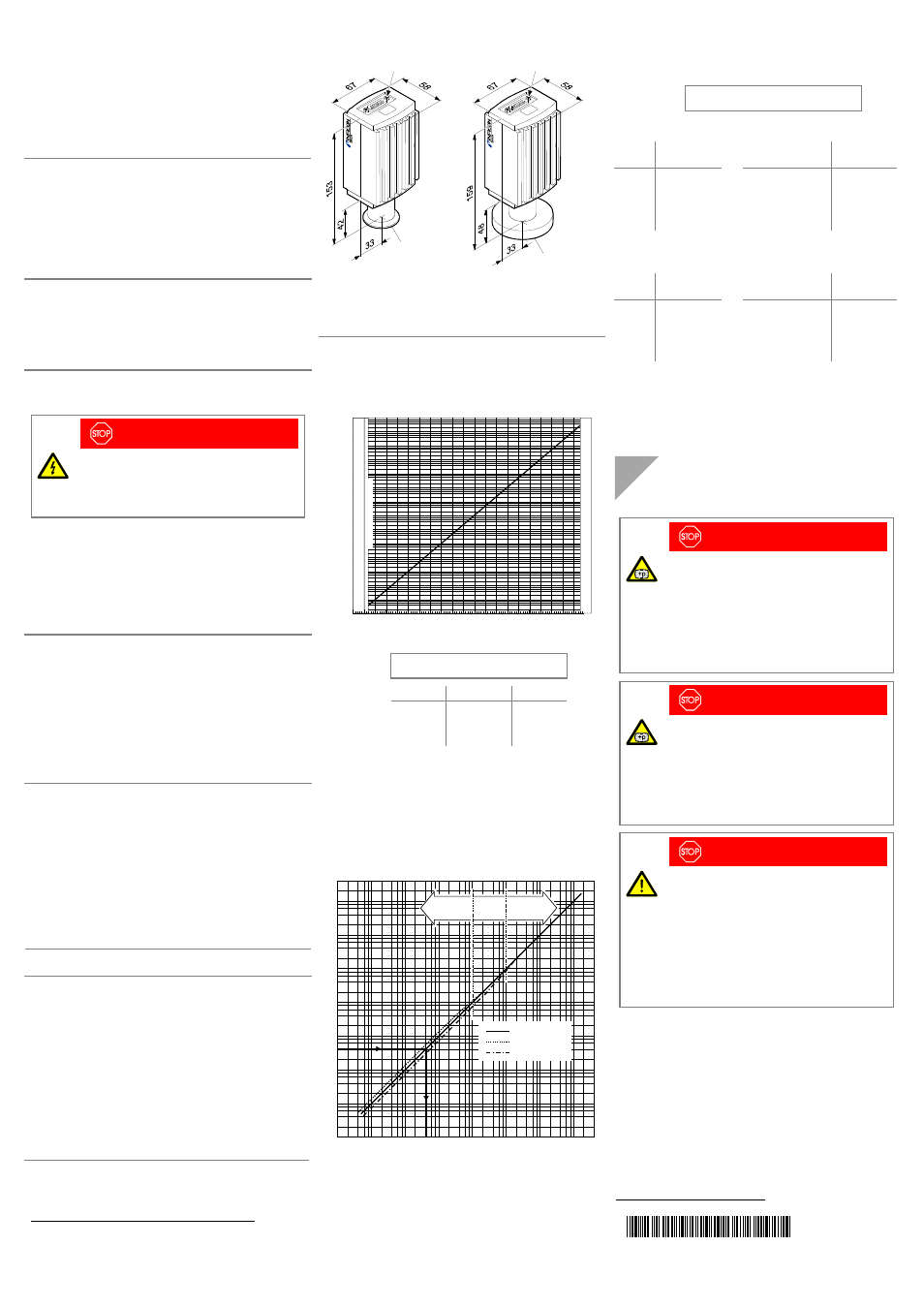

Measuring Signal vs. Pressure

1E+01

1E–01

1E–03

1E–05

1E–07

1E–09

1E+03

Measuring signal U[V]

0.0

1E+04

1E+02

1E+00

1E–02

1E–04

1E–06

1E–08

1E–10

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

Pressure p [mbar]

In

a

dmis

sib

le

ran

ge

S

ens

or

er

ro

r

In

ad

m

is

sible ra

ng

e

p = 10

(U-7.75)/0.75+c

U p c

[V] [mbar] 0

[V] [Pa] 2

[V] [Torr]

-0.125

where p pressure

U measuring

signal

c

constant (pressure unit dependent)

Gas Type Dependence

Indicated pressure (gauge calibrated for air)

10

2

8

6

4

2

10

1

8

6

4

2

10

0

8

6

4

2

10

–1

8

6

4

2

10

–2

8

6

4

2

10

–3

10

–4

2

4 6

10

–3

2

4 6

10

–2

2

4 6

2

4 6

10

0

2

4 6

10

1

10

–1

10

–4

p

eff

[mbar]

2

4 6

10

2

2

4 6

10

3

8

6

4

2

10

3

p [mbar]

8

6

4

2

4

2

2

Air, O

2

, CO, N

2

He

Ar

Pirani

sensor

Cross-

over

range

Capacitance

diaphragm

sensor

Calibration factors

(Gauge calibrated for air)

p

eff

= C × pressure indicated

Valid for Pirani pressure range 2×10

-2

… 1 mbar:

Gas

type

Calibration

factor C

Gas

type Calibration

factor C

He

Ne

Ar

Kr

Xe

0.8

1.4

1.7

2.4

3.0

H

2

air, O

2

, CO, N

2

CO

2

H

2

O vapor

freon 12

0.5

1.0

0.9

0.5

0.7

Valid for BA pressure range

≤5×10

-3

mbar:

Gas

type

Calibration

factor C

Gas

type Calibration

factor C

He

Ne

Ar

Kr

Xe

5.9

4.1

0.8

0.5

0.4

H

2

air, O

2

, CO, N

2

2.4

1.0

(Indicated factors are average values.)

Installation

Vacuum Connection

DANGER

DANGER: overpressure in the vacuum system

>1 bar

Injury caused by released parts and harm

caused by escaping process gases can result if

clamps are opened while the vacuum system is

pressurized.

Do not open any clamps while the vacuum sys-

tem is pressurized. Use the type clamps which

are suited to overpressure.

DANGER

DANGER: overpressure in the vacuum system

>2.5 bar

KF flange connections with elastomer seals (e.g.

O-rings) cannot withstand such pressures.

Process media can thus leak and possibly

damage your health.

Use O-rings provided with an outer centering

ring.

DANGER

DANGER: protective ground

Incorrectly grounded products can be extremely

hazardous in the event of a fault.

The gauge must be electrically connected to the

grounded vacuum chamber. This connection

must conform to the requirements of a protective

connection according to EN 61010:

• CF connection fulfill this requirement

• For gauges with a KF flange, use a conduc-

tive metallic clamping ring

t i ma 4 0 e 1 - b

(2011-04)

Original: German tima40d1-b (2011-04)