INFICON Cool Drawer Single Sensor User Manual

Page 46

4 - 6

PN

07

4-

60

9-

P1

A

Cool Drawer Single and Dual Sensors Operating Manual

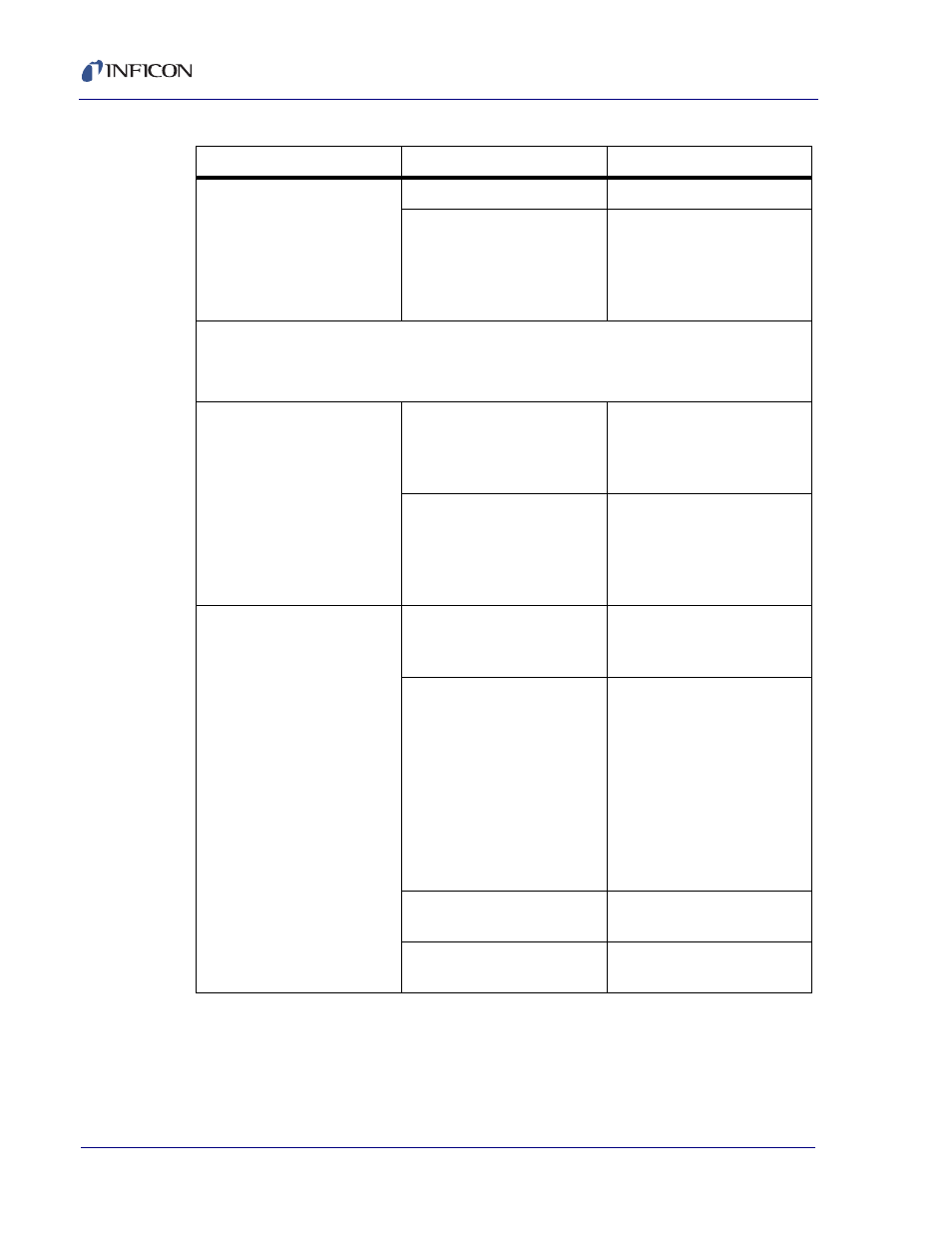

Crystal does not oscillate or

oscillates intermittently (both

in vacuum and in air).

Damaged crystal.

Replace the crystal.

Existence of electrical short

or poor electrical contacts.

Check for electrical continuity

and short in sensor contacts;

check for electrical continuity

in feedthroughs, refer to

NOTE: Check the leaf spring contact shape as part of a routine maintenance inspection.

Flattened or deformed leaf spring contacts in the retainer are common causes of

crystal problems. Lift up each retainer contact spring to a height of approximately

3.3 mm (0.13 in.). See

.

Crystal oscillates in vacuum

but stops oscillation after

open to air.

Crystal is near the end of its

life; opening to air causes

film oxidation, which

increases film stress.

Replace the crystal.

Excessive moisture

accumulation on the crystal.

Turn off cooling water to

sensor before opening it to

air; flow hot water through

the sensor when the

chamber is open.

Thermal instability: large

changes in thickness reading

during source warm-up

(usually causes thickness

reading to decrease) and

after the termination of

deposition (usually causes

thickness reading to

increase).

Crystal not properly seated. Check and clean the crystal

drawer. See

.

Excessive heat applied to the

crystal.

If heat is due to radiation

from the evaporation source,

move sensor farther away

from source and use Low

Thernal Shock crystals for

better thermal stability; if the

source of crystal heating is

due to a secondary electron

beam, change to a sputtering

sensor.

No cooling water.

Check cooling water flow

rate.

Heat is from electron flux.

Use sputtering head for

non-magnetron sputtering.

Table 4-1 Symptom, Cause, Remedy (continued)

SYMPTOM

CAUSE

REMEDY