Feed counter, Service / maintenance, Trouble shooting – Hydrolevel VXT-120 V1 User Manual

Page 4: Step, Attach service tag

Feed Counter

The VXT’s built-in feed counter records the number of gallons that enter the boiler during automatic feed cycles

or when the

FEED button is pressed.* To determine how much water has been added to the boiler since the last service, the counter should

be checked, recorded, and reset each time the boiler is serviced. The counter reset (DISPLAY RST) button is located in the

bottom right corner of the circuit board.

The addition of water to a boiler raises the oxygen level and accumulates lime and other mineral deposits over time. Excessive

feed cycles, resulting from leaks in the system, can cause cast iron boilers to oxidize (rust) internally, significantly reducing the

life of the boiler. Lime and sediment build-up can impede heat transfer causing damage and/or premature failure of the boiler.

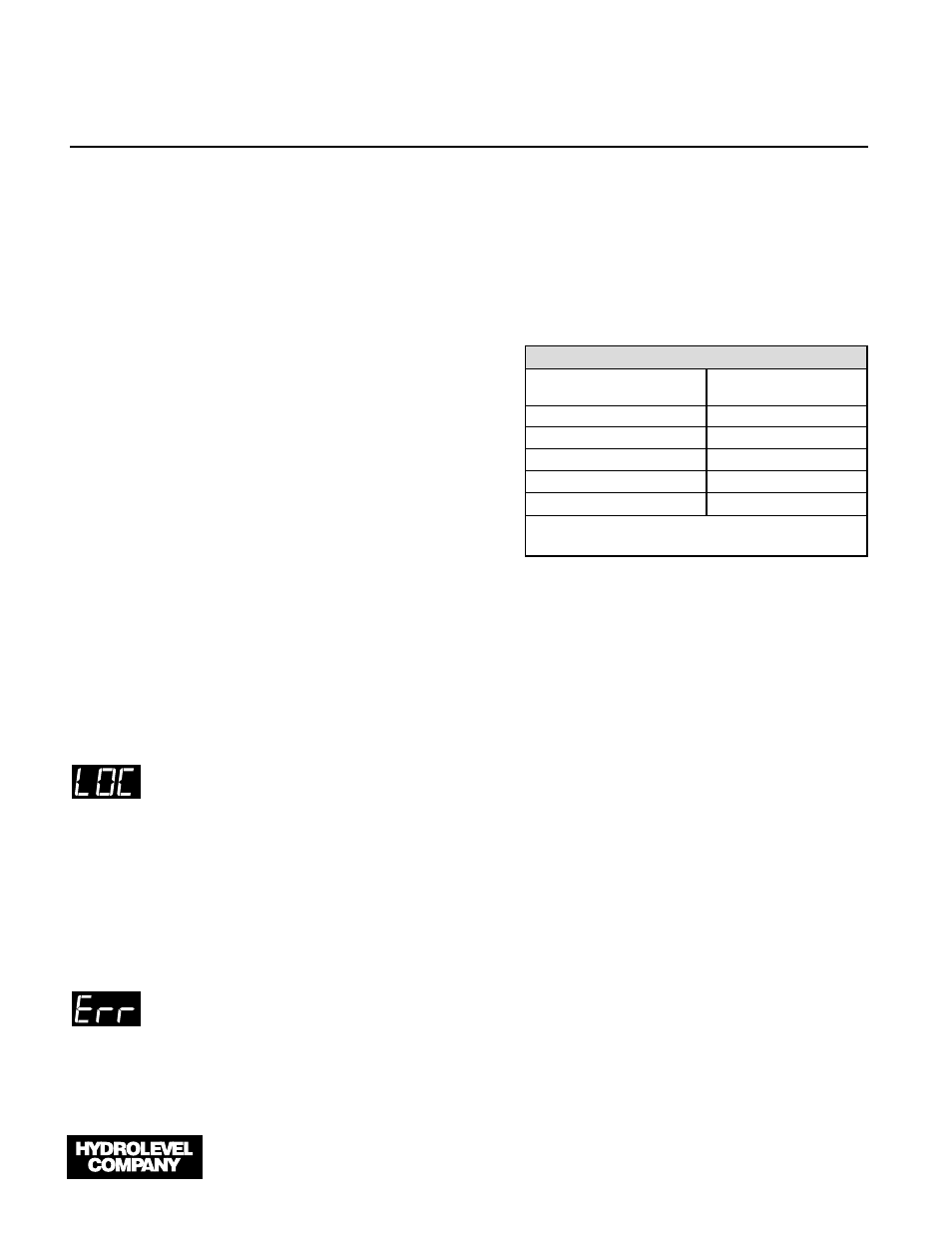

Recommended Limits on Make-Up Water

Many factors, such as the water capacity of the boiler, feed water con-

ditions and boiler design can impact the amount of water that can safe-

ly be added to a steam boiler. As a general guideline for late model

boilers, Hydrolevel recommends the monthly limits in the table at the

right for boiler operation during the heating season. If feed amounts

significantly exceed these levels, the system should be checked for

leaks by a qualified technician. Note: Any feed limits provided by the

boiler manufacturer supercede Hydrolevel recommendations. Please

check the boiler manufacturer’s instructions carefully.

*The VXT Feeder is equipped with an orifice to regulate flow rates over a wide range of

water pressures. The Feed Counter readings are designed to be accurate to ±15% with

water pressures between 20 to 90 PSI.

Service / Maintenance

Check Feeder Operation: Feeder operation should be checked annually during boiler servicing to ensure proper operation

and feed amount.

Record and Reset Feed Counter: The feed counter should be checked annually. If the feed amount falls within the recom-

mendations provided in the table above, record this amount on the card provided and press the reset button (DISPLAY RST)

on the bottom right corner of the circuit board. Note: If the feed amount significantly exceeds the recommendations above, the

system should be checked for leaks by a qualified technician.

Trouble Shooting

If LOC appears in the digital counter, this indicates that the safety lockout feature is activated. This feature

engages only when the feeder completes two consecutive feed cycles and the low water cut-off does not re-ener-

gized the burner. The feeder can be reset by briefly interrupting power to the heating system. Important: The following trouble

shooting steps should be taken to determine the cause of the lockout condition before restoring normal operation.

1. If the boiler is overfilled, the low water cut-off is not functioning properly. Using the manufacturer’s instructions, check the

low water cut-off operation.

2. If the boiler is in low water:

a. Check boiler and return piping for leaks.

b. If no leaks are detected, check to determine if the flow of the feeder is restricted. Check isolation valves around feeder

to ensure they are fully opened.

c. Check the feeder setting to ensure that it is set to feed adequate water in the event of a low water condition.

If ERR appears in the digital counter, this indicates that more than one or no delay or feed button has been select-

ed. See Step 4 and Step 5 for DELAY and FEED setting instructions.

Step

➏

– Attach Service Tag

Complete the information at the top of the service tag provided and attach tag near the VXT Water Feeder.

P.O. Box 1847 • New Haven, CT 06508 • Phone: (203) 776-0473 • FAX: (203) 773-1019 •

www.hydrolevel.com

Recommended Make-Up Water Limits

Net IBR Rating

Gal/month

MBH

Limit

Up to 90,000

6

91,000 - 120,000

8

121,000 - 150,000

10

151,000 - 185,000

12

185,000 & Higher

15

Note: The above limits are based on normal boiler operation during the heat-

ing season. They do not include water added as a result of boiler and/or low

water cut-off maintenance.