8troubleshooting – Hydrolevel 3150 User Manual

Page 8

8

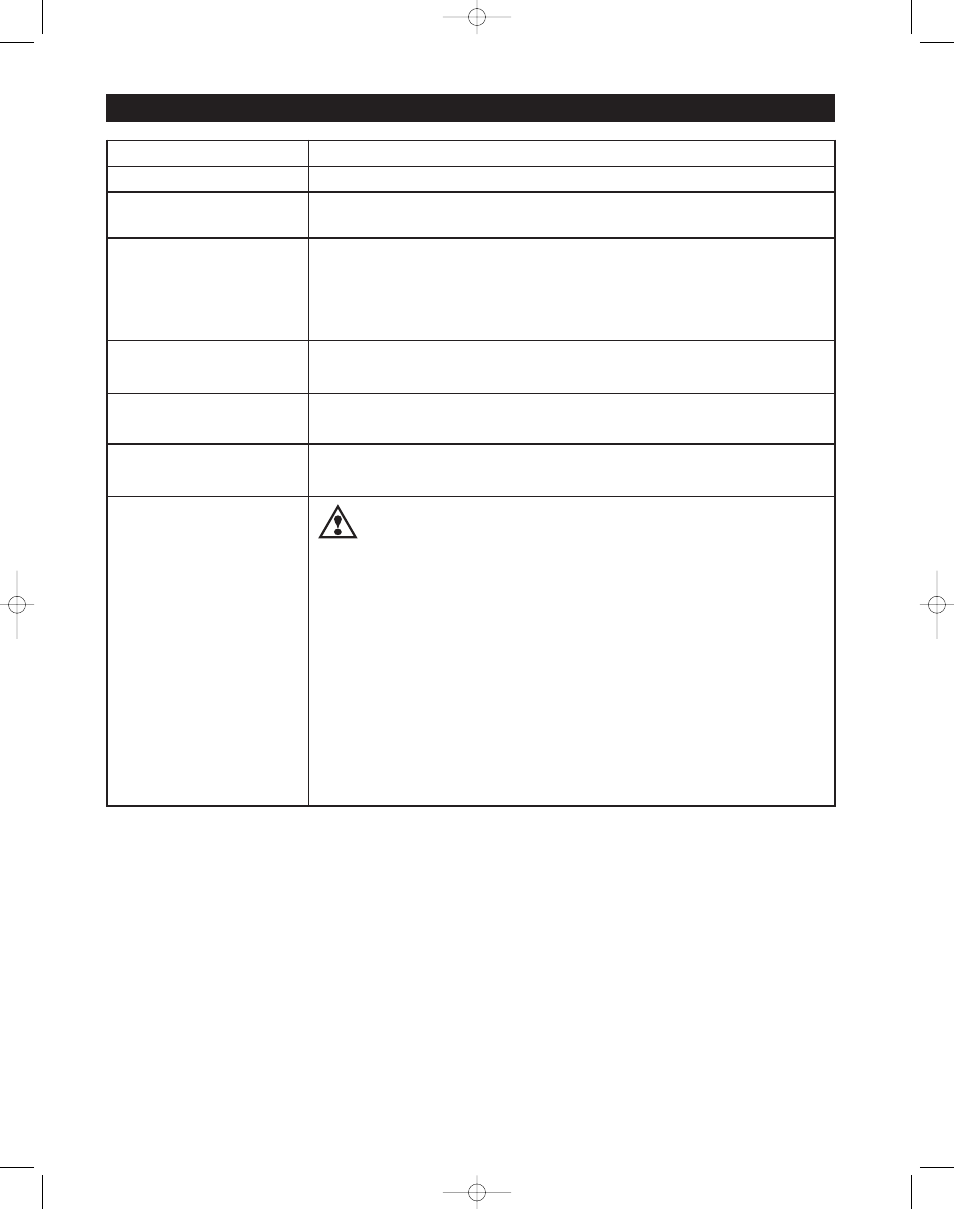

TROUBLESHOOTING

Burner Will Not Fire

See Flow Chart 1, page 9

Burner Will Not Shut Down

See Flow Chart 2, page 10

Temperature Display Exceeds High

Limit Setting

Under normal operation, boiler temperature will continue to rise after the control shuts off the burner.

This condition, known as “thermal stacking”, results from hot boiler surfaces continuing to release

heat into the boiler water.

No or Insufficient

Domestic Hot Water

If the boiler has a tankless coil make sure the low limit setting on the HydroStat is set properly.

NOTE: If the low limit setting is dialed fully counter clockwise, it will shut off the low temperature

maintenance feature and will function as a cold start control. Faster hot water response may also be

achieved by turning off the Thermal Pre-Purge Feature (see page 4). If boiler is operating in con-

junction with an indirect water heater, check to be sure the temperature control on the indirect tank

is set properly. Make sure any valves in between domestic hot water heating device, boiler, and hot

water taps are open.

Boiler Will Not Maintain

Low Limit Temperature

Check for overlapping high temperature setting. If the high limit setting is set below the low limit

setting, the control will default to the high limit setting and the corresponding high limit differential

setting.

Temperature Display

Differs from Boiler

T&P Gauge Temperature Reading

Temperature variances can result from differing water temperatures within the boiler or different

reaction times of the two devices. If the HydroStat temperature is significantly below the T&P gauge

temperature, make sure the thermistor is inserted all the way to the end of the well.

LWCO “Active” Light

(Green LED) Is Not On

The HydroStat will only provide low water cut-off functionality when used in conjunction with an

insulated Electro-Well™. When attached to a standard immersion well, the LWCO “Active” light will

remain off and the HydroStat will provide temperature functionality only.

Low Water Light

(Red LED) Is On

or Blinking

WARNING: A low water condition is a serious and potentially

dangerous condition. Do not attempt to add water to a hot boiler.

Allow the boiler to fully cool before adding water.

When Installed on an Electro-Well™

When the LOW WATER light is on, this indicates that the control is not detecting water in

the boiler. When the LOW WATER light is blinking, this indicates that the control has

been programmed to provide low water lock-out protection and is currently locked out

(see Manual Reset Low Water Cut-Off on page 5). Pressing the TEST/SETTINGS button

after the low water condition is resolved will reset the lock-out condition.

1. If the light is on and the heating system is filled with water, pull the sensor out of the

well and inspect it. Make sure that the metal clip is protruding enough to come in

contact with the inside of the well tube. Check that the well does not have excessive

build-up of heat transfer grease that may interfere with the clip contacting the well.

2. Remove well and examine for excessive residue build-up. Clean and re-install.

When Installed on a Standard Immersion Well

If either LWCO LED lights are illuminated and the control is installed on a standard

immersion well, this is a false reading caused by a loss of continuity between the sensor

and the inside of the well tube. It is recommended when the control is installed on a

standard immersion well, the LWCO Function be turned off (see page 6 for details).

HydroStat 3150 Instructions Page 8