Operating instructions, Maintenance – Hydrolevel CGT450 Series User Manual

Page 3

Operating Instructions

NOTE

For proper low water cut-off operation, the boiler should be cleaned at

initial installation and periodically thereafter. Refer to the boiler manu-

facturer’s instructions for cleaning procedures.

OPERATING TEST PROCEDURE

1. After installation, bring the boiler water to a safe operating level, turn

on power and set the thermostat to call for heat. The amber LED

lamp should be off. The boiler will fire immediately.

2. Slowly lower the boiler water to a point below the probe. The amber

LED lamp on the control will light. The lamp may begin to flicker with

the bouncing water level. Stop draining the boiler when the lamp

glows steadily. NOTE: The water should not be lowered beyond a

visible point in the gauge glass.

3. The boiler will shut down within 15 seconds.

IF BURNER DOES NOT SHUT DOWN IN LOW WATER

1. Check terminal block wiring to insure that all connections are cor-

rect.

2. Check the probe installation to insure that there is 1/4" clearance

from any surface within the boiler or pipe. (Refer to Step 3 on page 1

of this instruction sheet.

3. Clean the boiler in accordance to the manufacturer’s instructions.

Machining oils, grease, rust and other contaminants in the boiler

water can cause foaming or surging and make a low water condition

difficult to detect during burner operation.

IF THE AMBER LED LAMP IS ON

The amber LED lamp indicates that the water is below the probe. If the

gauge glass shows that the water is at the correct operating level and

the amber LED is lit check the following:

1. Check for plugged gauge glass.

2. Make sure probe lead wire is properly secured to the terminal.

3. Check for proper ground between probe and boiler shell. Excessive

use of Teflon tape or sealing compound may isolate the probe from

the boiler shell.

4. Remove probe and examine for oily residue. Clean probe with steel

wool and skim boiler.

IF THE GREEN LED LIGHT IS ON

The green LED lamp indicates that the control is conducting an

Intermittent Level Test. The burner does not fire during the test period.

See Intermittent Level Test Feature on this page for more details.

Maintenance

To ensure optimum performance remove and inspect probe annually.

Clean any sediment or scale from the probe using a scouring pad or

steel wool. Re-install the probe and perform the Operating Test

Procedure described above.

To provide added protection to today’s smaller boilers, the

CycleGard low water cut-off is equipped with an Intermittent

Level Test. This important feature adds protection against

false signals that can be caused by foam and volatile water

conditions inside the boiler. The Intermittent Level Test

removes power from the burner at preset intervals. During the

test, foam dissipates and the water level stabilizes – allowing

CycleGard to monitor the true water level in the boiler assur-

ing safe and accu-

rate operation.

The last four digits

of the CycleGard

model number

determine the fre-

quency and dura-

tion of the Intermittent Level Test (ILT) as shown in the table.

When the optional SmartCycle feature

is activated (see wiring instruction on

previous page), the CycleGard’s test

time sequencing is restarted each

time the burner fires. This feature enables a full burner run

cycle (10 or 20 minutes, depending on model) prior to the

first Intermittent Level Test. On CGT450 models (designed for

boilers equipped with tankless coils), SmartCycle suspends

the Intermittent Level Test during a call for domestic hot water

allowing the boiler to deliver its full BTU capacity to the pro-

duction of hot water.

CycleGard

Intermittent

Level Test

Feature

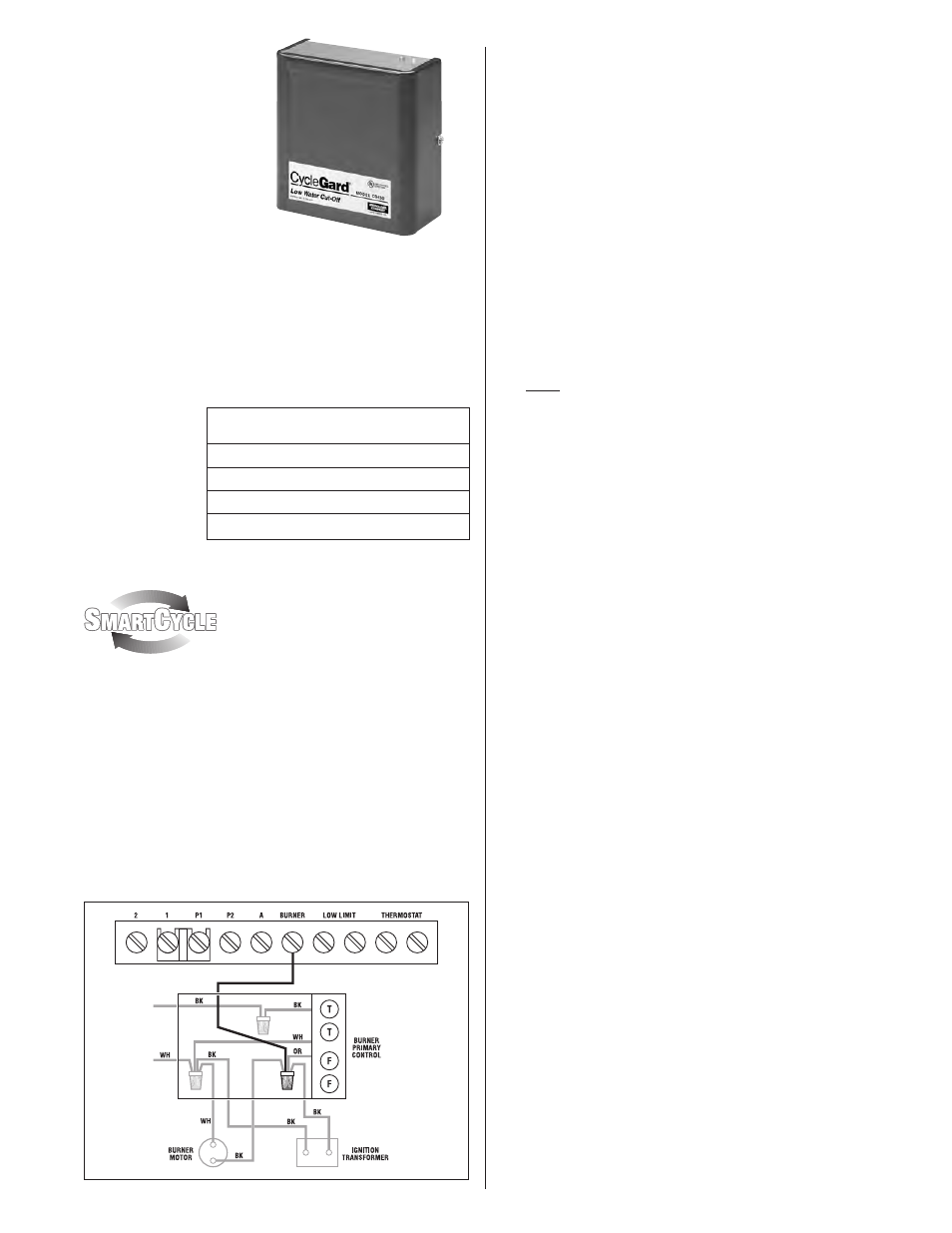

Burner Connection

Model CG450 and CGT450

Last 4 digits

Frequency

Duration

of Model No.

of ILT

of ILT

1090

10 Minutes

90 Seconds

1560

15 Minutes

60 Seconds

2060

20 Minutes

60 Seconds

2090

20 Minutes

90 Seconds