Hydrolevel 450 Series User Manual

Page 2

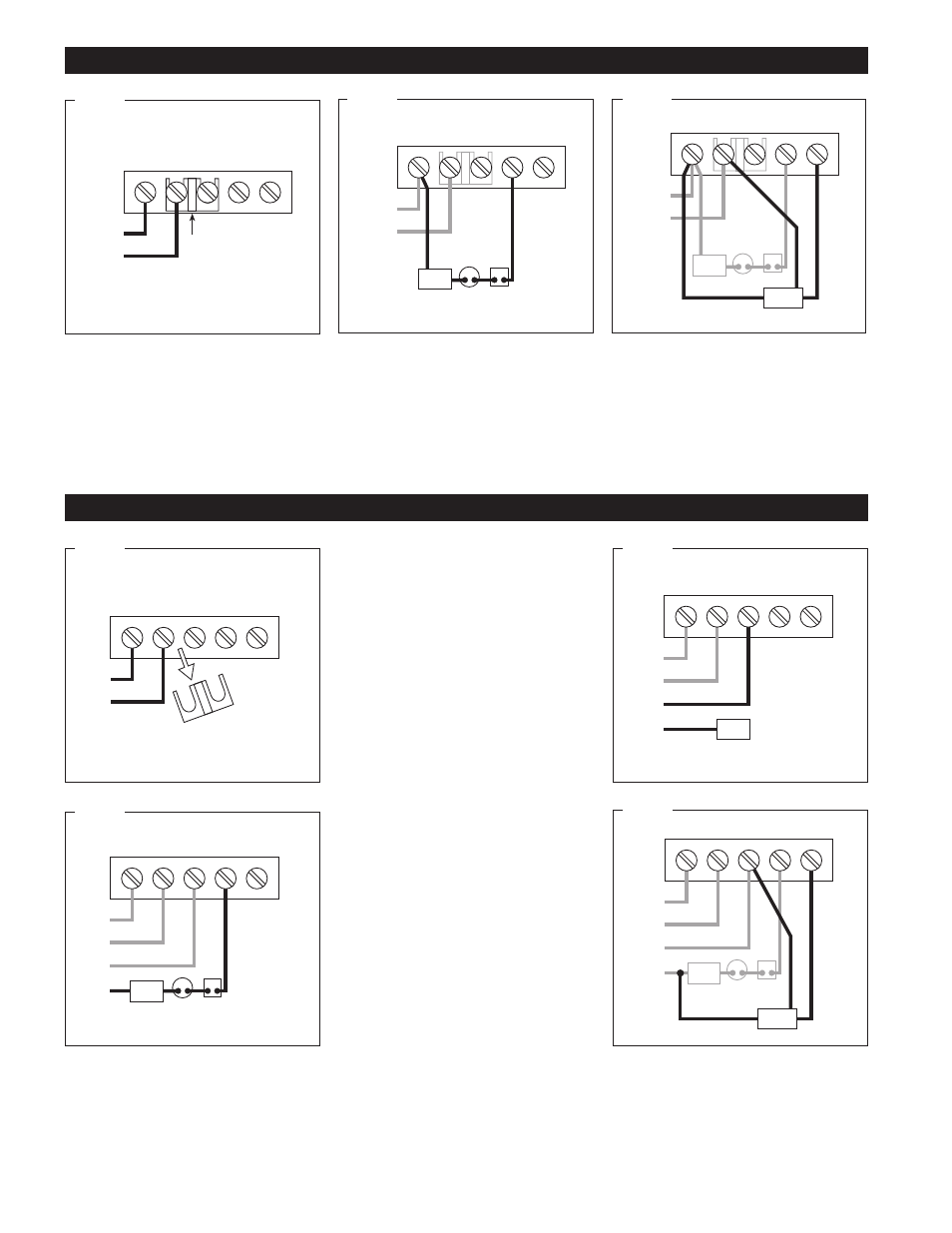

A1

Connect input voltage (120 VAC, 60 HZ)

to terminals 1 and 2. 120 VAC, 60 HZ must be

supplied to terminals 1 and 2 for internal opera-

tion of the control.

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

BURNER

CIRCUIT

HOT

NEUTRAL

FEEDER

OR ALARM

HOT

NEUTRAL

BURNER

CIRCUIT

A

P2

P1

1

2

BURNER

POWER

SOURCE

(24 or

120VAC)

BURNER

POWER

SOURCE

120VAC

A

P2

P1

1

2

FACTORY

INSTALLED

JUMPER

NEUTRAL

HOT

BURNER

POWER

SOURCE

120VAC

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

HOT

NEUTRAL

BURNER

CIRCUIT

120VAC

A

P2

P1

1

2

REMOVE

JUMPER

NEUTRAL

HOT

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

BURNER

CIRCUIT

HOT

NEUTRAL

BURNER

POWER

SOURCE

120VAC

+

0

LIMIT

CONTROLS

A

P2

P1

1

2

BURNER

CIRCUIT

WATER

FEEDER

WIRING METHOD A: SAME POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.

ᮤ

B1

Remove jumper between terminals 1

and P1. Connect input voltage (120 VAC,

60 HZ) to terminals 1 and 2. 120 VAC 60 HZ

must be supplied to terminals 1 and 2 for inter-

nal operation of the control.

Connect hot lead from the burner

B2

ᮣ

ᮣ

control circuit to terminal P1. This terminal sup-

plies power to terminal P2 in normal operating

conditions when water is at the probe. Connect

neutral to burner circuit. Note: consult boiler

manufacturer instructions for proper terminal

connections.

ᮤ

B3

Connect terminal P2 to burner circuit

in series with and before other limit controls.

Optional water feeder connection.

B4

ᮣ

ᮣ

Connect feeder H to terminal P1. Connect feeder

“FEED” or “W” to terminal A. Connect terminal

N to neutral of the burner circuit supply. For

feeders with two leads, connect feeder hot to

terminal A and connect feeder neutral to neutral

of the burner circuit supply. Note: Use of sole-

noid valve or McDonnell & Miller model 101A

water feeder may cause flooding and is not rec-

ommended for use with this low water cut-off.

A2

Connect terminal 2 to burner circuit neu-

tral. Connect terminal P2 to burner Circuit in

series with other limit controls. Consult boiler

manufacturer instructions for proper terminal

connections. Control should be wired in series

with and before other limit controls.

A3

Optional water feeder connection.

Connect feeder N to terminal 2. Connect Feeder

H to terminal 1. Connect feeder “FEED” or “W”

to terminal A. For water feeders with 2 leads,

connect feeder neutral to terminal 2 and feeder

hot to terminal A. Note: Use of a solenoid valve

or McDonnell & Miller Model 101A water feeder

may cause flooding and is not recommended

for use with this low water cut-off.

A1

A2

A3

B1

B3

B2

B4

WIRING METHOD B: SEPARATE POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.